Toothed Double Roll Crushers

Price:

Get Latest Price

In Stock

Product Overview

Key Features

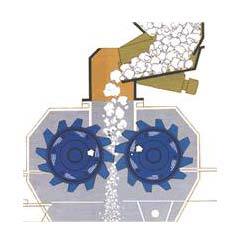

Due to cutting action of the teeth, crushing of material takes place mostly due to shear and not by pressing. Therefore fines generation is bare minimum.

Description:

Crushing takes place due to two rolls running in to each other and crushing the material caught in the valley of the rolls. One roll is fixed, while other one is adjustable & spring mounted, permising of uncrushable to pass through.

Crushing Rolls:

Toothed rings are mounted on the heavy fabricated hub and the rings are kept in position by holding bolts. These rings are made of wear-resistant steel, like 1 4% Mn Steel, K.M.D. or any other hardened Steel depending upon the application.

Drive through V belts or through Gear Box/Geared Motor.

Gap Adjustment:

The design of the ECOMAN's Gap-Adjustment system is such, that during running condition gap can be adjusted and also the spring force. There are two spindles located one inside the other in such a way, that inner spindle tightens or lessens the springs, while outer one changes the position of the roll. Attached sketch is self-explanatory.

Company Details

Business Type

Exporter, Manufacturer, Service Provider, Distributor, Supplier, Wholesaler, Dealer, Fabricator, Producer

Employee Count

175

Establishment

1982

Working Days

Monday To Sunday

GST NO

24ABZPG4301Q1Z7

Related Products

Explore Related Categories

Seller Details

GST - 24ABZPG4301Q1Z7

Vadodara, Gujarat

Asst. Manager (marketing)

Mr Jayesh Jadhav

Members since

15 Years

Address

Factory:- 906/4, GIDC, Near Kiran Motors, Makarpura, Vadodara, Gujarat, 390010, India

double roll crusher in Vadodara

Report incorrect details