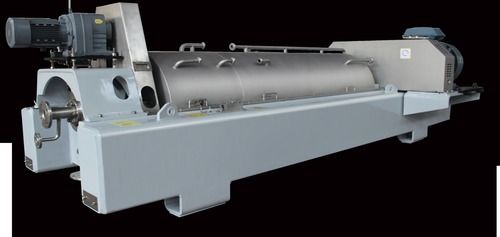

Top 3 Phase Sludge Dewatering Horizontal Decanter Centrifuge

Price:

Get Latest Price

In Stock

Product Overview

Key Features

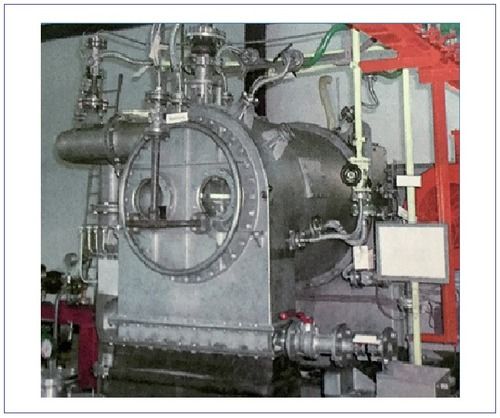

TOP 3 phase Sludge dewatering Horizontal Decanter Centrifuge

1-Feeding pipe;2-Main motor belt pulley;3-Main bearing oil injecting nozzle;4-Bearing of screw;5-Spiral vane;6-Rotary drum;7-Bearing of screw;8-Main bearing;9-Main bearing oil injecting nozzle;10-Secondary motor belt pulley;11- Main bearing;12-Solid discharge;13-Outlet;14-Liquid discharge;15-Liquid baffle;16-Differential;

Working principle:

The suspension, through the feeding pipe 1, goes from the outlet 13 into the drum 6.Under the centrifugal force generated by high-speed rotation, the solid particles of large proportion deposited on the inner wall of the drum, the spiral vanes 5, performing relative movements with respect to the drum, continuously scrap the solid particles deposited on the drum wall and rolled to solid discharge 12. After-separation clear flow out through opening 14 on liquid layer adjusting plate. The relative movement between the spiral vanes and the drum is called differential rotation, which is realized by the differential 16. Its scope is controlled by secondary motor, thus realizing the continuous separation process of centrifuge.

Product advantages(Product performances):

Good adaptability: All kinds of special requirements of raw material and technique on centrifuge are fully considered in the design. the main function parts are improved in speciality and adjustability. As long as users explain the location of their installation, physical and chemical characteristics and process requirements, we will provide users the most suitable models.

High degree of automation

Good running stability: The differential used by centrifuge is second-stage involute planetary gear differential, which adopts the unique low oil level operation technology of our factory, with low working temperature, large transmission torque and reliable performance.

Strong technique:The centrifuge adopts dual motors, double frequency conversion energy feedback differential speed system, which can realize flexible speed regulation and online intelligent control for differential speed, and adjust differential speed at any time according to the change of material.

Corrosion resistance:drum , screw body, hood and other parts contacting with material are made of high quality stainless steel

Good operating environment

Complete safety protection device: Torque protection, power control, vibration and temperature measurement and other multiple protection.

Good appearance

Selection table for specifications and technical parameters of decanter centrifuge

Company Details

Business Type

Exporter, Manufacturer, Supplier

Employee Count

80

Establishment

2002

Working Days

Monday To Friday

Related Products

Explore Related Categories

Seller Details

Chengdu, Sichuan

Sales Manager

Ms Selena

Address

No.146 of Konggang, 2nd Road, Southwest Airport Economic Development Zone, Shuangliu, Chengdu, Sichuan, 610220, China

decanter centrifuges in Chengdu

Report incorrect details