Toughen Plant

Price:

Get Latest Price

Product Overview

Key Features

1.1.Main Technical Parameters

1.1.1.Glass thicknessi 4-19mm

1.1.2.Glass sizei 2440A 3660mmi Maxi for Glass thickness is 4-19mmi

150x250mm (Min)

For 4mm glass, the Max load area is 2440x1500mm

1.1.3.Prodcct standardi Standard for Tempered Glass GB9963-2000

1.1.4.Production ratei a Y95%

1.1.5.Capacityi 145M2/hi 5mm glass ,85%loading ratei

1.2.Power capacity

1.2.1Intsallation power

1.2.1.1.Heating sectioni 580KW

1.2.1.2 Driving systemi 10KW

1.2.1.3.Cooling bloweri 250 KW (total)

1.2.1.4.Total Power Capacityi 630KVA

1.2.2.Panumatic airi Flow 0.6M3i mina Max Pressure: 0.8MPa

Tank volume: 0.5M3

1.3.Suitable glassi

Float glass, Coated glass, Color Glass.

1.4.Supply scopei

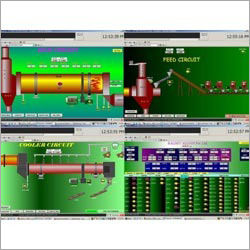

Loading table, Unloading Table, Heating furnace, Tempering section, Electrical control system, blowers , Inverter for blower , Ventilation pipe system.

Company Details

Business Type

Exporter, Importer, Manufacturer, Supplier

Employee Count

200

Establishment

1980

Working Days

Monday To Sunday

GST NO

06AENPB5313E1ZZ

Related Products

Explore Related Categories

Seller Details

GST - 06AENPB5313E1ZZ

Faridabad, Haryana

Proprietor

Mr Balwinder Singh

Members since

23 Years

Address

111-G, DLF Industrial Area, Phase-1, Faridabad, Haryana, 121003, India

sponge iron plant in Faridabad

Report incorrect details