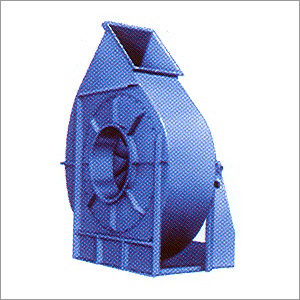

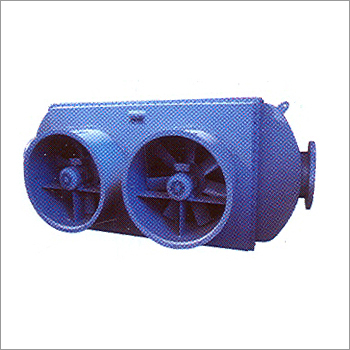

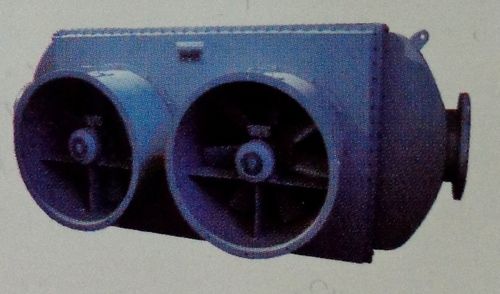

Transfer Finned Type Heat Exchanger

Price:

Get Latest Price

In Stock

Product Overview

Key Features

Company Details

Business Type

Manufacturer, Supplier

Employee Count

400

Establishment

1980

Working Days

Monday To Saturday

GST NO

09AAACS1005N1ZG

Payment Mode

Cash Advance (CA)

Certification

ISO 9001:2000 Certified Company

Related Products

Explore Related Categories

Seller Details

GST - 09AAACS1005N1ZG

Noida, Uttar Pradesh

H.o.d. - Vacuum Marketing

Mr Ramesh Bajpai

Address

C-2, Sector-3, Gautam Budh Nagar, Noida Noida, Uttar Pradesh, 201301, India

plate heat exchangers in Noida

Report incorrect details