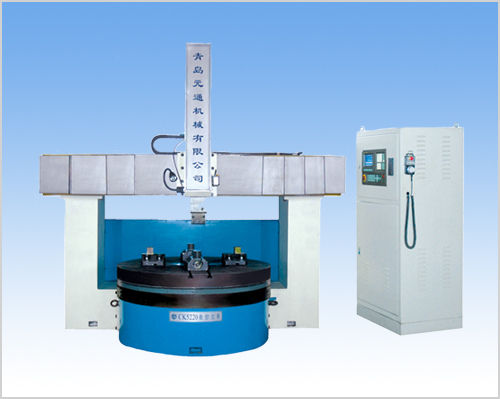

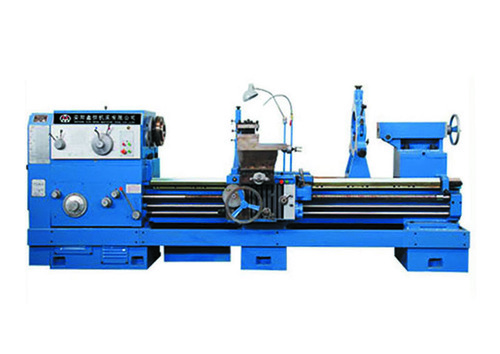

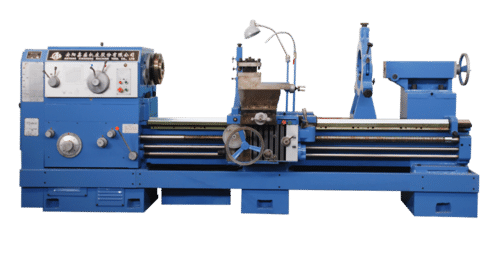

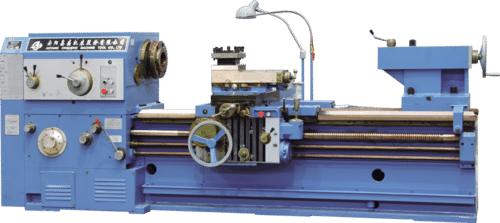

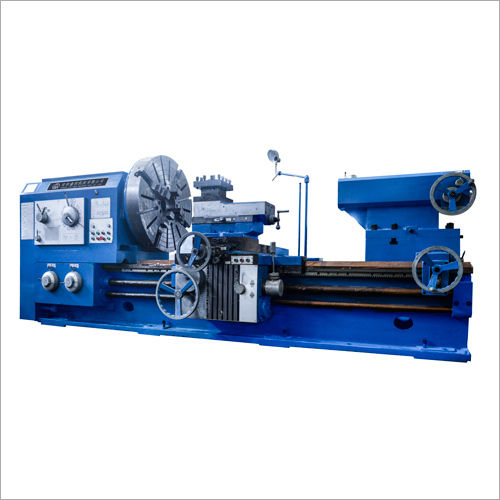

Universal Conventional Lathe For Turning Pipe, Cylinder, Shaft, Propeller

Price: 18000 USD

Get Latest Price

Minimum Order Quantity :

1

In Stock

Product Specifications

| Product Type | Conventional Lathe |

| General Use | Shaft, Pipe, Cylinder, roll, propeller machining |

| Material | Metal |

| Capacity | 2000 Kilogram(Kg) |

| Weight (kg) | 6000 Kilograms (kg) |

| Computerized | Yes |

| Automatic | Yes |

| PLC Control | Yes |

| Bar Feeder | Yes |

| Power Source | Electric |

| Power Consumption | 11 Kilowatt (kW) |

| Rigidity | High |

| Voltage | 440V,380V,220V are all available Siemens Volt (S ) |

| Motor | AC Motor |

| Table Size | 320-6000 mm |

| Spindle Speed | 10-800 RPM |

| Axial Choice | X,Z axises |

| Dimension(L*W*H) | 5700*2100*2100 Millimeter (mm) |

| Color | Gray |

| Warranty | 1 year warranty |

| FOB Port | Qingdao |

| Supply Ability | 300 sets Per Year |

| Delivery Time | 60 Days |

| Sample Policy | Contact us for information regarding our sample policy |

| Packaging Details | Wooden Box Package |

| Main Export Market(s) | Australia, North America, Eastern Europe, Middle East, Western Europe, Africa, South America, Asia, Central America |

| Main Domestic Market | All India |

| Certifications | ISO9001, BV, SGS, etc |

Product Overview

Key Features

A

1. Outstanding Characteristics:A

Our company was established in 1969 as a military enterprise at the beginning. With more than 50 years experience, we are specialized in re-designing and manufacturing customized lathe machines per your special demands and requests.

This series lathe machine has both turning and Grinding functions, it can be called CNC machining center also. It can help you save time and improve efficiency for the part which needs to be truned and Grind like marine/vessel propeller shaft, A

1). Reasonable Structure and excellent performance.A

2.). High Rigidity, Stability and Precision Maintenance

3.) Permanent After-sale Service to ensure maximum customer's profitability. A

4.) Engineers are available for over-sea installation,commissioning and Training the operators in customer's factory.A

5.) All components for machine are freely provided within 3 days by Air to prevent customer's production suspended and minimum customer 's loss.A

A

6.) A The Main machine components are strictly inspected by the advanced CMMA to ensure the excellent quality and high precision.A

Our Principle : Maximize Customer's Profitability under the minimum invest cost.

Application:A This series CNC horizontal lathe can utilize high-speed steel and carbide cutting tools to finish rough or finish turning process for not only the non-ferrous metals like various structure steels, casting steels and irons, but also the external/internal cylindrical / conical/ spherical surfaces, thread of non-metal materials and all kinds of the surface of curve rotary body. What's more, it can also realize the constant speed cutting line. It has both turning and milling functions that can finish machining the part one time, which saves clamping times and improve the working efficiency for customers.A

A

2. Technical Parameters

NameCG61100CG61125CG61160CG61200CG61250CG61300

DescriptionA Unit

Max. Swing Over Bedmm100012501600200025003000

Max. Swing Over the skateboardmm6508001200165018002800

Max. Weight of Work-pieceT101520202040

Max. Length of Work-piecemm3000-12000

Gears of Spindle Speed/Infinitely Variable Speed/step-less speed

Range of Spindle Speedr/Min10-30010-20010-1604-804-801.6-63

Chuck Diametermm80010001250160020002500

X,Z-Axis Feed Rangemm/Min0-3000

Horizontal Strokemm500625800100012501000

Longitudinal Strokemm3000-12000

Main Driving MotorKw112245757575

Cutting Force (Carriage)Kn4620404060

Sleeve Diameter of Tailstockmm180180290290290480

Spindle Diameter of tailstockmm125125160160160240

Remarks:A

1. The above 6 models of Heavy Duty Horizontal CNC Lathe Machine are the standard configurations, we can also design and manufacture customized lathe machines according to the user's work-piece features.A

2. This series heavy duty horizontal CNC Lathe Machine have been exported to Norway, Thailand, Romania, Iran, Russia, Chile for machining railway parts, automobile parts, mining and metallurgy, shipping building, wind power and other machinery industry.A

Company Details

Business Type

Exporter, Manufacturer, Service Provider, Supplier

Employee Count

150

Establishment

1969

Working Days

Monday To Saturday

Certification

ISO9001, BV, SGS

Related Products

Explore Related Categories

Seller Details

Qingdao, Shandong

Marketing Department

Ms Anna Sun

Address

Liuting Industrial Park, Qingdao, Shandong, 266108, China

cnc lathe in Qingdao

Report incorrect details