Upper And Lower Side Slitter Sip Cutter Core Material: Customized

Price Trend: 100.00 - 1000.00 USD

Get LatestPrice

| Life Span | Depends on the steel material and your request |

| Tolerance | Depends on your request Millimeter (mm) |

| Core Material | customized |

| Material | Steel |

| Shaping Mode | Plastic Mould |

Product Overview

Key Features

We are indulged in making and exporting Upper and Lower Side Slitter SIP Cutters in Wuxi, Jiangsu, China.

Specification - high performance; large supply ; on-time delivery

Brand Name: OEM

Die Type: punch

Draw Format: Auto CAD/DWG/PDF etc

Tolerance: A 0.002mm

Hardness: Upon request

Mould size: Customized size

Production Application: automobile/ electron / air conditioner /refrigerator etc

Surface Treatment: Polishing/ mirror polishing/ plating/ heat treatment or according to your parts

Precision Machining: CNC/ surface grinding machine/ punching machine/ wire cutting/ EDM/ WIDA optical curve grinder etc

Measuring Instruments: Profile projector/ electronic height gauge/ 2D measuring instrument/ caliper/ microscope/ micrometer etc

Steel Material: KD20/ DC53/ GD650/ SKD11/ SLD/ YG15/ CR12MOV/ SKH-9/ Tungsten etc

Mould Life: Depends on the steel material and your request

Main Service: Made-to-order

Main characteristics:

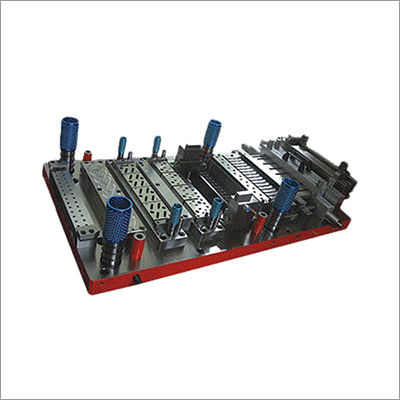

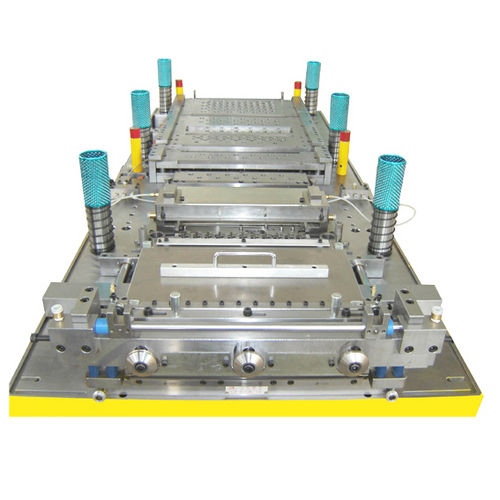

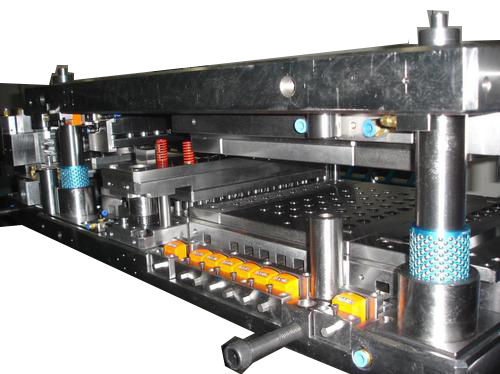

The fin die includes upper & lower die plates; draw & form station; pierce extrude sub-die, louver sub-die; edge trim station; longitudinal cut sub-die; mechanical feeder station; cut-off station; the fin die and sub-dies are provided with guidepost, guide sleeve, and ball retainer.

The pierce extrude sub-die and louver sub-die have the ball support bushings to lengthen the service life of the piercing and louver puncher.

The drawing and forming punch, dowel pin and piercing die are all made of tool steel, with machining, heat treatment, shaping grinding and polishing.

Upper & lower piercing punch & die are made of customized material with machining, heat treatment.

Upper and lower side slitters, upper and lower slitter, cut-off blades are made of customized material with milling, heat treatment and grinding.

The die plate and sub die are made of high carbon steel with CNC processing, homogenizing, grinding and assembly.

Specification - high performance; large supply ; on-time delivery

Brand Name: OEM

Die Type: punch

Draw Format: Auto CAD/DWG/PDF etc

Tolerance: A 0.002mm

Hardness: Upon request

Mould size: Customized size

Production Application: automobile/ electron / air conditioner /refrigerator etc

Surface Treatment: Polishing/ mirror polishing/ plating/ heat treatment or according to your parts

Precision Machining: CNC/ surface grinding machine/ punching machine/ wire cutting/ EDM/ WIDA optical curve grinder etc

Measuring Instruments: Profile projector/ electronic height gauge/ 2D measuring instrument/ caliper/ microscope/ micrometer etc

Steel Material: KD20/ DC53/ GD650/ SKD11/ SLD/ YG15/ CR12MOV/ SKH-9/ Tungsten etc

Mould Life: Depends on the steel material and your request

Main Service: Made-to-order

Main characteristics:

The fin die includes upper & lower die plates; draw & form station; pierce extrude sub-die, louver sub-die; edge trim station; longitudinal cut sub-die; mechanical feeder station; cut-off station; the fin die and sub-dies are provided with guidepost, guide sleeve, and ball retainer.

The pierce extrude sub-die and louver sub-die have the ball support bushings to lengthen the service life of the piercing and louver puncher.

The drawing and forming punch, dowel pin and piercing die are all made of tool steel, with machining, heat treatment, shaping grinding and polishing.

Upper & lower piercing punch & die are made of customized material with machining, heat treatment.

Upper and lower side slitters, upper and lower slitter, cut-off blades are made of customized material with milling, heat treatment and grinding.

The die plate and sub die are made of high carbon steel with CNC processing, homogenizing, grinding and assembly.

Product Specifications

| Life Span | Depends on the steel material and your request |

| Tolerance | Depends on your request Millimeter (mm) |

| Core Material | customized |

| Material | Steel |

| Shaping Mode | Plastic Mould |

| FOB Port | Shanghai |

| Payment Terms | Cash on Delivery (COD), Letter of Credit (L/C), Paypal, Others, Western Union, Letter of Credit at Sight (Sight L/C), Delivery Point (DP), Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Days after Acceptance (DA), Cash in Advance (CID), Cheque, Cash Advance (CA) |

| Supply Ability | 1000 Per Month |

| Delivery Time | 10 Days |

| Sample Available | Yes |

| Sample Policy | Free samples are available |

| Packaging Details | Standard export packing for Parts: aEURC/With plastic bag, with pearl-cotton package. aEURC/To be packed in cartons. aEURC/Use glues tape to seal cartons. Or according to customers' requirement. aEURC/Packing: plastic bag + bubble wrap+ box/carton + wooden box |

| Main Export Market(s) | Australia, Middle East, Western Europe, Central America, Africa, South America, Asia, Eastern Europe, North America |

| Main Domestic Market | All India |

| Certifications | DIN,JIS,ISO,MISUMI,PUNCH,DAYTON,HASCO,FIBRO,LANE, and DME standards |

Company Details

WUXI SIP INDUSTRY Co.,Ltd is a highly specialized manufacturer and trader of mould and die components .

Sip process various of mold components according to supplied special drawings and also according to DIN,JIS,ISO,MISUMI,PUNCH,DAYTON,HASCO,FIBRO,LANE, and DME standards.

Types of mould and die parts include air conditioner and heat exchanger fin die spare parts, spare parts for return bend machine and cooper tube; Press and plastic mould components; Precision semicon pin series; Carbide parts and hot runner valve pinsa

Based on the knowledge of precision machining, Sip also produces other precision machining components according to customersa designs or samples.

Set up by technologists with 20 years in the mold components industry, processed by well trained workers, goods can be ensured with qualified quality and timely delivery. Serviced by sellers with years of international business, you will always be satisfied.

Sipa s mission is to work with mold industries partners together and create a win-win share!

Business Type

Exporter, Manufacturer, Service Provider

Employee Count

10

Establishment

2013

Working Days

Monday To Saturday

Payment Mode

Telegraphic Transfer (T/T)

Seller Details

Sip Industry Co.,Ltd

Name

Eva Qian

Address

Room 1016,No.286, Changjiang North Road, Xinwu District, Wuxi, Jiangsu, 214028, China

fin die in WuxiReport incorrect details

Related Products

More Products From This Seller

Explore Related Categories

Recommended Products

Popular Products

Human HairForklift TrucksServo Voltage StabilizerBasmati RiceBackhoe LoaderCarry Bag Making MachineDrum LifterElectric StackerScissor LiftsIndustrial Vibrating ScreenRotameterFlowmeterRotary Air CompressorIndustrial Eto SterilizerRice Packaging MachinesShredding MachineHammer MillAutomatic Labelling MachineDiesel ForkliftAerial Work PlatformStorage Rack SystemEpoxy ResinMild Steel BarStainless Steel SheetsStainless Steel StripsBag Filling MachinesAsphalt PlantsSlat ConveyorOintment PlantPlanetary MixersLadies KurtisLed LightsCctv CameraBall ValveAnti Cancer MedicineAir CompressorIncense SticksSolar LightsGoods LiftsVitrified TilesStainless Steel CoilsPvc PipesPvc Pipe FittingsUpvc PipesUpvc Ball ValvePipe Elbows