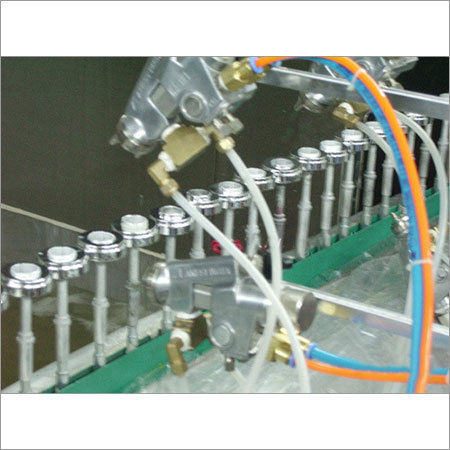

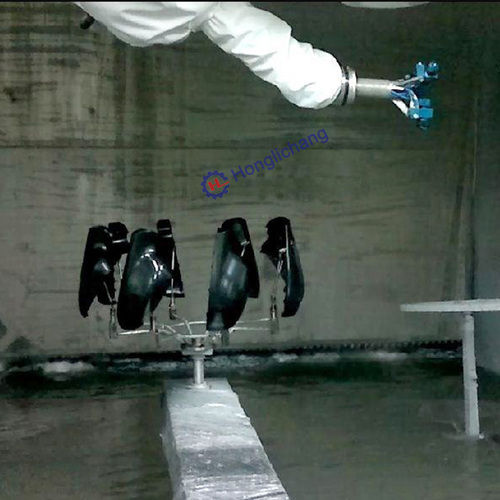

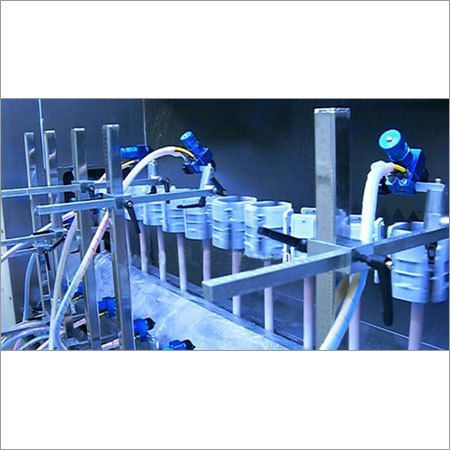

With the support of our workforce, we are continuously able to manufacture, export and supply a quality array of UV Metalising Coating Line for Bottle Caps. Highly demanded for its efficient functioning and easy maintenance, this line is widely used in paint and chemical industries to offer an optimum solution of painting by spraying on tank, components and many more. At our well-versed manufacturing setup, this line is manufactured by utilizing excellent quality components and the advanced technology. Tested on various parameters, the offered UV Metalising Coating Line for Bottle Caps is available at reasonable rates to the clients. Features: Easy to operate and high in performance It requires negligible maintenance User friendly operations Ensures longer functional lifeIdeal for various plastic, automobile, injection molded plastic part Process of UV Metalising Coating Line for Bottle Caps:1. We prepare a design of a 2-spraybooth coating line: loading-flame treatment-ionization-primer coat booth-flashoff-topcoat spraybooth-UV flashoff-UV preheating-UV oven-cooling and unloading-metalising. As per the design, post metalising process, you need to carry the metalised lamp to the original loading area and do again the preceding process (only stop the flame treatment booth, primer coat booth). By doing this, the conveyor will operate without any work therefore, some of the electricity energy will be lost due to the fact that the entire procedure is not continuous. Nevertheless, this functional design will save you purchasing cost.The various devices in this design are: conveyor-1, ionization booth-1, flame booth-1, spray booth-2, flashoff section-2, UV oven-1, IR oven preheating-1, metalising plant-1 (and also air shower and AHU)2. We make a design of a 3-spray booth coating line: loading-flame treatment-ionization-primer coat booth-flashoff-topcoat spray booth-UV flashoff-UV preheating-UV oven-cooling and unloading-metalising-loading-ionization-topcoat spray booth-UV flashoff-UV preheating-UV oven-cooling, unloading and packing. In such design, the entire process is constant, different from the 2-spray booth line. You can observe the devices in this design are: conveyor-1(longer), ionization booth-2, flame booth-1, spray booth-3, flash off section-3, UV oven-2 (air shower and AHU extra), IR oven preheating-2. Therefore, as per this design, your purchasing cost will be greater (nearly double the price of the first design) but operating cost will be saved.Application of UV Metalizing Coating Line for Bottle Caps ( Cosmetic Bottle Cap Automatic UV Coating Line )This type of Automatic UV Coating line is popularly used for application in camera casing, painting phone casing, toy, music player casing, LCD panel, pen casing, cosmetic bottle caps, wine bottle caps, etc., while the acceptability can touch 95% mark and the quality stands unchanged.Type of Available Lines:Cosmetic Bottle Cap Automatic UV Coating LineUV coating lineAutomatic UV coating lineDustfree UV coating lineUV Spray Coating LineTurnkey UV coating lineUsed for different Automobile Parts, Plastic Parts, or Injection Moulded Plastic Parts