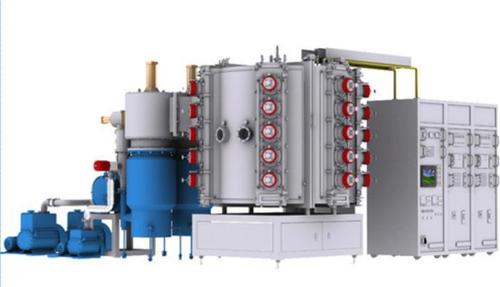

Vacuum Metallizing Machine - 2500mm Coating Width, High-speed 800m/min | Electric Drive, Plc Control, Customized Color Options, Advanced Cooling System

Price Trend: 350000.00 - 800000.00 USD

Get Latest Price

Minimum Order Quantity :

1

In Stock

Product Specifications

| General Use | food packaging flexible packaging battery film |

| Weight (kg) | 50000 Kilograms (kg) |

| Coating Speed | 12 m/s |

| Coating Head | Gravure Roller |

| Coating Width | 2500 Millimeter (mm) |

| Coating Material | Plastic |

| Computerized | Yes |

| Automatic | Yes |

| Control System | PLC Control |

| Power Source | Electric |

| Heating System | Electric |

| Drive Type | Electric |

| Voltage | 410 Watt (w) |

| Humidification System | No |

| Rewinder Type | Single Rewinder |

| Unwinder Type | Duplex Unwinder |

| Dimension(L*W*H) | 18000*8000*45000mm Millimeter (mm) |

| Color | customized |

| Warranty | 1 YEAR |

| FOB Port | shanghai |

| Supply Ability | 30 Per Year |

| Delivery Time | 5 Months |

| Sample Policy | Contact us for information regarding our sample policy |

| Packaging Details | factory standard packaging |

| Main Export Market(s) | North America, Eastern Europe, Africa, Central America, Middle East, South America, Western Europe, Asia, Australia |

| Main Domestic Market | All India |

| Certifications | ISO9001 |

Product Overview

Key Features

Substrate: PET, CPP, OPP, PE, PVC and Paper

Application: Food packaging film, flexible packaging holographic film, tobacco packaging paper, anti-counterfeit packaging, battery/capacitor film, hot stamping materials, and high-class print package material.

Introduction:

1. Evaporating boat type vacuum metallizer mainly utilized to metalize all kind of plastic thin film and special treatment paper that used for packaging industry, capacitor or other new energy industry, anti-counterfeit industry, decorating industry, textile and other industries. The new technology of metalizing 4.5 micron PET film with both side metalized by one time has been No. one in China.

2. The steady and reliable winding system, normal winding speed is up to 600-700m/min, maximum speed up to 800m/min, film width range is 1000mm-3000mm.

3. Free span type or drum touch type metalizing system as per customer requirement on film, in this case maxi guarantee metalizing performance and quality.

4. High quality core parts: 1, Siemens motor and inverter, Siemens touch screen and PLC control, 2, Germany Leybold pump or other international brand pump, 3, Imported SKF bearing 4, High quality Polycold system or USA Polycold, 5, Main and sub roller cooling system.

Feature:

1. Evaporation boat adopt a stagger clampinga method, same group electrodes independently inlet & outlet of cooling water, greatly improves the cooling effect and ensure the evaporation performance and laid a good foundation for improving metallizing speed, and improve evaporation boat life.

2. Stagger arrangement ensures good reliability, larger evaporation volume, better uniformity of metallizing, and eliminate the phenomenon of trim line and pinhole.

3. According different user requirements to improve the main drum size, leaving more room for the layout of the winding system, ensuring better cooling and winding effect when metalizing.

4. In regard to the defense of aluminum slag, we assimilate advantage of Leybold Germany, not let the aluminum slag enter into, ensuring the corona value namely ensuring the printing quality, well received by users.

5. In terms of cooling and heating system, we increased the cooling liquid storage, adopts double compressor system, shortened the time back to the temperature, increase product output, reduce the electricity consumption, thus relatively increased profits for the user.

6. Inside the winding chamber, except for the evaporation shutter, all the connecting pipes adopt hard tube, which eliminates the phenomenon of pipe explosion caused by pressure too large and pipe aging when once adopt rubber connecting pipe.

7. About cooling roller size, enlarge the size of second cooling drum which greatly ensuring the metalizing quality. Drum coating reaching to -20a can cooling the heating systems to prevent film thermal damage.

8. Evaporation coaming adopts the latest German technology, four sides all use whole aluminum plate, but our companies have made improvement on it again, make sure good uniformity and power saving, reducing phenomenon of striking a light

9. Optional multi-channel non-contact thickness measurement system measures film sheet resistance and optical density, providing accurate analysis for product quality control.

10. Four Siemens motors drive technology to assure high availability, reliability and extreme speed. Maximum winding speed can reach to 800 m/min, which greatly increases the production efficiency.

Company Details

Focusing on a customer-centric approach, Sichuan Sis Vacum Technology Co., Ltd. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Coating Machine in bulk from Sichuan Sis Vacum Technology Co., Ltd. at Trade India quality-assured products.

Business Type

Exporter, Manufacturer

Employee Count

50

Establishment

2008

Working Days

Monday To Sunday

Related Products

Explore Related Categories

Seller Details

Chengdu, Sichuan

Manager

Mr Bright

Address

Dragon Industry Zone, Lognquanyi District. Chengdu, Sichuan, 610100, China

vacuum coating machine in Chengdu

Report incorrect details