Ventury Scrubber - High-quality Air Purification Solution | Efficient Impurity Removal For Industrial Ventilation Systems

Price:

Get Latest Price

In Stock

Product Specifications

| Product Type | Air Scrubber |

| Dominant Color | Light Blue |

| Material | Steel |

| Dimensions | Variable |

| Pressure Drop | 10-20 kPa |

| Efficiency | 90-99% |

| Usage | Industrial air purification, removing particulate matter and gaseous impurities from factory emissions |

| Compliance | EPA compliant |

| Features | High efficiency, Dust removal, Gas cleaning, Low emissions, Easy maintenance |

Product Overview

Key Features

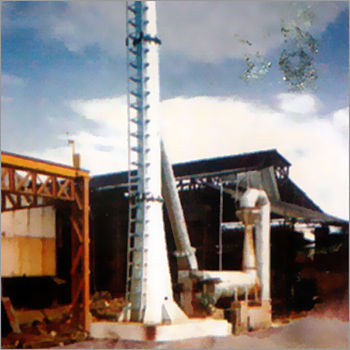

With the support of our high-ranking professionals, we are able to manufacture, export and supply high quality Ventury Scrubber. These scrubbers are installed in factories to remove impurities, dust and other particles from the air. Our team of expert professionals fabricate these systems by making use of latest machines and tools. We procure quality materials and components from the reliable vendors of the market which are used to fabricate these scrubbers. The Ventury Scrubber is quality examined and tested before delivery to ensure high performance and durability.

Other information:

Scrubbers have played a very important role in industrial ventilation for many decades. These are only devices, which can remove particulate matter as well as gaseous impurities. Wet scrubbing of industrial gases has improved over many years to accommodate fine cleaning requirements of todays industry. Any activity like burning metal forming, chemical reaction or material handling will generate pollutants like particulate matter, unwarranted gases and these pollutants need to be removed from the gas stream and cleaned gases are to be left in the atmosphere to ensure the environment fit for living creatures.

Scrubbers can be grouped into 2 types. Type 1 is for particulate collection, where equipment like wet cyclones, cyclonic scrubbers and venturi scrubbers are involved, and type 2 is for gaseous absorption / removal, where equipment like static packed bed, dynamic packed bed, baffle plate scrubbers or impingement plate scrubbers are involved. These divisions are only for understanding the finer aspects of wet collectors and there is no hard and fast rule about which collector can be used. A decision can be arrived at only by experience and from the results available.

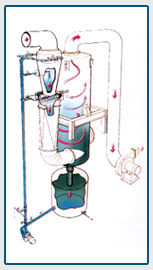

Process of wet collection occurs in following 3 basic operations:

Saturation of the incoming dirty gases

Contacting and capturing of contaminants

Separation of contaminants/liquor from the cleaned gases

Wet collectors capture dirty gases transform item into liquid slurry and in solution or suspension for disposal into effluent treatment plant. Depending on the application, wet collectors can be designed for particulate removal or gaseous removal.

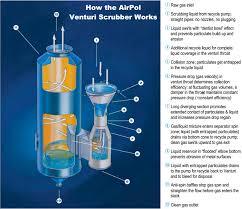

Venturi Scrubber

In its simplest form a venturi scrubber consists of a constriction in a gas duct, into which water is introduced. The scrubbing occurs at the restriction, where high gas velocities atomize the water into fine droplets. After scrubbing, the gas and water are separated in a cyclonic separator, the water gravitating to a pumping tank for re-use and the clean gas leaving from the top of the separator.

Features affecting design and performance of Venturi:

Assuming that the gas conditions are known, the other major considerations affecting a venturis performance are the size analysis of the particulates, the pressure drop across the venturi and to a lesser extent the L/G ratio.

Advantages:

High temperature gases will not create any problem. These will be cooled and washed in one equipment.

Corrosive gases can be neutralized simultaneously with the collection of particulate matter also.

Soluable material may be recovered and pumped in slurry form for additional treatment, if necessary.

Possibility of fire or explosive hazard is eliminated.

When gases are near due point condition, wet collectors avoid the problem or building up sticky deposits on dry surface. This is an important factor to be considered before going in for a dry system with a pre-cooler. If the dew point is very high one will have to insulate the dry system.

Typical Applications:

Some of the typical applications for wet collectors are:

Gas cleaning for blast furnaces, boiler flue gas

Black liquor recovery for pulp and paper

Refusal incineration scrubbing

Dolomite lime kiln exhaust

Zinc oxide fume collection

Aluminium smelting furnace exhaust ventilation

Bagasse fired and oil fired stream/power generation

Apart from these, non-metallic scrubbers are used for acid scrubbing, SO2 scrubbing and NOx scrubbing.

Company Details

Aswathi Industries Limited is an ISO 9001: 2015 Certified Company engaged in providing turnkey solution for Air Pollution Control and Scrap Battery Recycling Plant. Company Started Way back in 1997 as designers, engineers & turn-key solution providers, having its Corporate Office & Manufacturing facility at Mumbai, India. Aswathi Industries Limited has full-fledged Design & Engineering team, manufacturing facility & team of experienced engineers for project execution, erection and commissioning of Plant & Machineries on turn-key basis. Our vast experience in various fields helps us to cater our services to various Industries viz Iron & steel, ferrous & non-ferrous industries, Chemicals & Pharmaceutical Industries. Our equipment are custom built to meet the individual requirement & we pay our special care to deliver user friendly solutions. Company has inherent mix of young /dynamic engineering talent with guided by experienced seniors. We are into Business of the following areas to serve the Industries with high quality & engineering excellence: Air Pollution Control Equipment, Used Lead Acid Battery recycling plants, Furnaces Heat Treatment & Reheating , Dryers Rotary & Spray dryers, Aluminium Scrap Recycling Plants, Hazardous waste Incineration System, Bio ÂA Medical Waste Incineration System, VOC Incineration/Thermal Oxidisers, Centrifugal Fans, Solution for Waste disposal systems, Material Handling Equipment.

Business Type

Exporter, Manufacturer, Supplier, Fabricator

Employee Count

300

Establishment

1997

Working Days

Monday To Sunday

GST NO

27AACCA0541R1ZJ

Certification

ISO 9001: 2015

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 27AACCA0541R1ZJ

Mumbai, Maharashtra

Sr. Manager Sales & Marketing

Mr. Atul Dehankar

Address

Apeksha Enclave Building, Ground Floor, Mahavir Nagar, Kandivali (W), Mumbai, Maharashtra, 400067, India

venturi scrubber in Mumbai

Report incorrect details