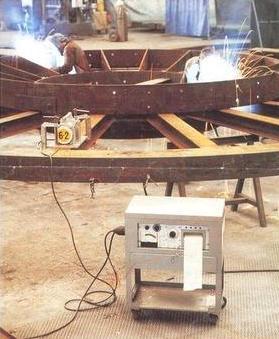

We offer to our valuable clients a wide range of Vibratory Stress Relief Machine that is manufactured in compliance with defined industry norms using quality approved components and high end technology. Offered machine can be used on any 220/230 volt, 50 Hz single phase power source at 100% duty cycle. Owing to features like impeccable performance, high strength and energy efficiency, this reliable machine is highly acclaimed by our clients spanning across market. The Vibratory Stress Relief Machine is available in various specifications at an economical price.Features Most effective means for reducing residual stresses by vibration. More pronounced stress redistribution compared to the sub resonant frequency methods. Are used as a carrier to deliver high amplitude energy to a metal fabrication, or machined part. Uses The process can be used on a wide range of ferrous and non-ferrous metals. Typical materials can be treated like carbon steels, stainless steel, aluminum, cast iron, manganese, incolnel, etc. Into a variety of conditions such as: wrought or cast, forged, formed, welded, ground, polished or machined. Characteristics: Heavy duty vibrator unit with attachment plate. Casters. A.C. supply cord. Accessory kit containing accelerometer, accelerometer clamp and coaxial cables. Instruction manual containing: Operating instructions, engineering information, maintenance manual, parts catalog, diagrams and trouble shooting guide. Unit comes with a written 3 year warranty. Technical Specifications Modes of operation: (3) manual, manual resonant/non-resonant, automatic. Variable frequency control. Analog resonance meter. Manual time indicator. Resettable circuit breaker protection. Cabinet size (inches): 16D x 26L x 33H (cm) 40.6D x 66L x 84H. Approx. Shipping Wt.: 168 Lbs. (76 Kgs.). Voltage Options: 200, 210, 220, 230, 50/60 Hz., 1 phase.