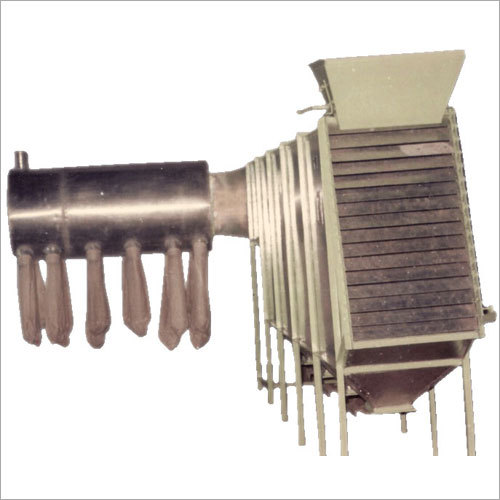

Vibroscreen Sorters

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Steel |

| Dimensions | Variable |

| Screens | Up To 5 |

| Motor | Variable |

| Capacity | Variable |

| Vibration | Multi-Plane |

| Discharge | Tangential |

| Features | High Capacity, Accurate Screening, Long Screen Life, Space Saving, Minimal Blinding, No Vibration, Multi-Screen, Precise Sizing |

Product Overview

Key Features

The top weight on the motor shaft rotates in plane close to the center of the mass of assembly. Rotation of the top eccentric weight creates vibration in the horizontal plane which causes material to move across the screen cloth to the periphery. Increasing the top eccentric mass increases the horizontal throw causing over size material to be discharged at a faster rate.

The bottom eccentric weight rotates below the center of the vibrating mass creating tilt on the screen causing vibration in vertical & tangential planes. Increasing the vertical component of this motion promotes turnover of material on the screen surface helping maximum quantity of undersize material to pass through the screen. The effective vertical motion helps in minimizing blinding of screen by near size particles.

The tangential component of this motion is controlled by the angle of lead given to bottom weights in relation to the top weight.

Variation in lead angle controls the spiral pattern of material travel over the screen cloth. Typical material travel patterns generated at various lead angles are shown below :

The material is fed on to the centre of top screen. The undersize material passes rapidly through the screen during its travel to the periphery. The oversize material gets continuously discharged through a tangential outlet. Vibroscreens are equipped to handle upto five different screens one on the top of the other with feed trays in between to give six precise sized fractions in single screening operation.

Salient Features & Advantages:

- Greater Capacity More Accurate Screening : Vibroscreen gives greater capacity per meter square of screening area and oversize material is discharged with relatively much less percentage of fines than other screening machines.

- Longer Screen Life : Screen cloth is held in uniform tension on specially designed mesh frames. The drum tight screening surface vibrates rigidly without flexing of wires, greatly reducing screen wear and increasing screen life.

- Less Space Required : For equivalent capacity, Vibroscreen requires less space than other screening systems. Compact units can fit into existing production lines.

- Minimum Blinding : Vibroscreen multi plane action limits screen blinding to an acceptable minimum. However for material having inherent blinding characteristics, Vibroscreen offers anti-blinding accessories to eliminate blinding.

- No Transmitted Vibration : No special flooring or foundation is required. The Vibroscreen may be placed wherever it is needed, like on top of bins, on wooden or upper floors or light structures.

Note:-Due to a continuous process of development the design is subject to change without notice.

Company Details

Business Type

Exporter, Manufacturer, Supplier

Establishment

1949

Working Days

Monday To Sunday

GST NO

19AAACT8460G1Z4

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 19AAACT8460G1Z4

Kolkata, West Bengal

Executive Chairman

Mr. Sajjan Bagaria

Address

11, Jassal House, 4-A, Auckland Square, Kolkata, West Bengal, 700017, India

tea processing machinery in Kolkata

Report incorrect details