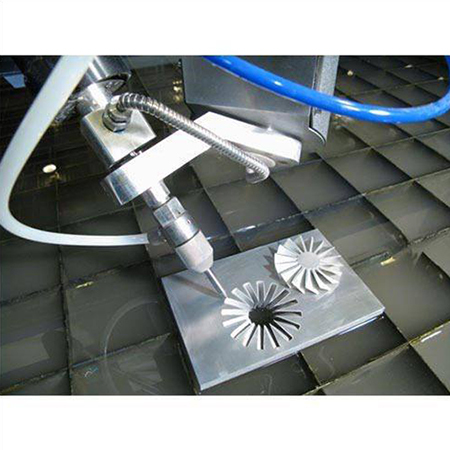

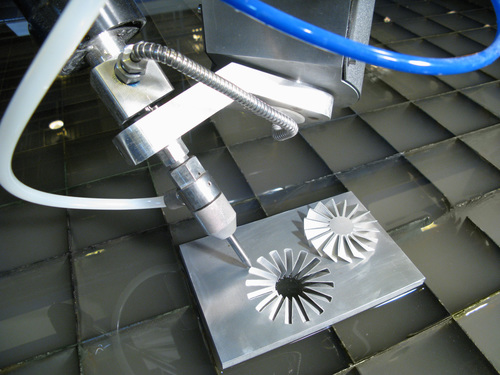

Waterjet Cutting - 2" Thick Sponge Rubber, ±.010" Tolerances, Clean Cut Edges Without Concavity

Price:

Get Latest Price

In Stock

Product Overview

Key Features

When and why to utilize WaterJet Cutting:

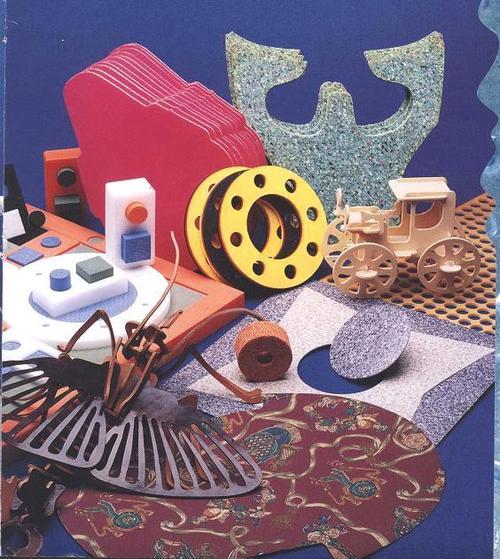

When parts are in the prototyping phase and designs are being proven. Waterjet cutting allows for design modifications without incurring multiple tool purchases.

When the material being used is expensive. Waterjet cutting offers tighter yields that can offset this more time intensive process.

When the part has adhesive on 2 sides. The edge quality of a waterjet part well exceeds that of a die cut part with adhesive on 2 sides.

When the part demands tight tolerances. Waterjet cutting in most cases, can hold tighter tolerances than die cutting.

When the part is complex. Waterjet systems are capable of cutting abnormal curves or odd geometry where tooling up a steel rule cutting die may be difficult.

When large gaskets are needed. Waterjet cutting large gaskets without having to commit to expensive tooling can be very beneficial.

When materials are thick, such as A " thick - die cutting may result in edge concavity. Waterjet cutting results in a clean edge without edge concavity.

Company Details

Focusing on a customer-centric approach, CMT CUTTING MACHINE TOOLS (SHANGHAI) CO., LTD. has a pan-India presence and caters to a huge consumer base throughout the country. Get Water Jet Cutting Machine from CMT CUTTING MACHINE TOOLS (SHANGHAI) CO., LTD. at Trade India quality-assured services.

Business Type

Exporter, Importer, Manufacturer, Service Provider, Supplier

Employee Count

18

Establishment

2011

Working Days

Monday To Sunday

Related Products

Explore Related Categories

Seller Details

Shanghai, Shanghai

Mr. Robert Tong

Address

255, Xinjinqiao Road #602, Pudong New Area, Shanghai, Shanghai, 201206, China

Report incorrect details