Welding Cables - Tpr Insulated, High Flexibility & Durability, Oil And Abrasion Resistant, Various Sizes Up To 120 Sqmm

Price:

Get Latest Price

In Stock

Product Specifications

| Conductor | Copper |

| Insulation | TPR |

| Sheath | Double |

| Sizes | 16-185 sqmm |

| Standards | IS 473 |

| Color | Orange |

| Applications | Welding, Power |

| Features | High Conductivity, Durable, Corrosion Resistant, Flexible, Abrasion Resistant, Heat Resistant, Reliable, Long Lasting |

Product Overview

Key Features

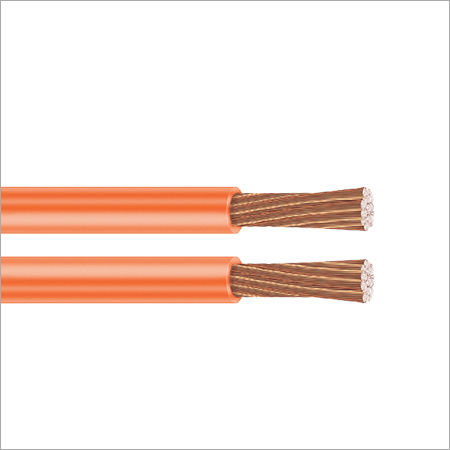

Welding Cables

We are involved in manufacturing and exporting a wide array of Welding Cables. Widely used in various institutions and industries, these are basically used for electrical conduction as well for lifting purpose such as lifts, and other heavy equipment. Moreover, these are developed with finest grade raw material procured from registered vendors of the market. Availed by us at reasonable market price, Welding Cables, offered are strong, corrosion resistant, reliable, durable and more.

FEATURES:

- Based on CENELEC HD 22-6 31, VDE 0282 ,IEC 245-6, IS 473, BS 638-4.

- Outstanding toughness & durability.

- High resistance to cuts , tears & abrasion.

- Resistance to oil , solvents and chemicals.

- Excellent ozone and weather resistant.

APPLICATIONS:

Welding: Designed for the secondary (high current) connection with automatic or hand - held metal arc welding electrodes. It is suitable for flexible use under rugged conditions, on assembly lines and converyor systems, in machine tool and automatically operated line and spot welding machines.

Power:

Earthing/return leads, power feeds to electrolytic plating process, Busbar connection, transformers, generators, aircraft servicing equipments etc.

CONSTRUCTION:

Conductor: High conductivity, bare annealed copper flexible conductor.

Sheath: Double sheathed with specially developed thermoplastic Elastomer (TPR/TPE), outer layer is orange coloured.

CURRENT RATING:

The maximum current ratings of flexible welding cables for different duly cycles are based on an ambient air temperature of 25 C and a maximum conductor temperature of 90 C. The percentage duly cycles for various processes and applications are as follows:

| 1 | Automobile Welding | upto 100% |

| 2 | Semi-automatic welding | 30% to 85% |

| 3 | Manual Welding | 0% to 60% |

| 4 | Very intermittent or Occasional Welding | upto 20% |

VOLTAGE DROP: When total cable lengths in excess of 15 meters, are involved , it may be necessary to use cables of larger cross section to ensure that the voltage drop is not excessive and welding currents are maintained at adequate levels.

| Cross - Sectional | Max. Conductorb resistance at 200C | Nominal Thickness of sheath | Min. Overall diameter | Max. Overall diameter | Current Ratings | ||||||

| Welding | Non Welding Application | ||||||||||

| Duty Cycle | |||||||||||

|

| 100% | 85% | 60% | 30% | 20% |

| |||||

| mm2 | ohm/km | mm | mm | mm | amp | amp | amp | amp | amp | amp | |

| 10 | 1.91 | 2.0 | 7.8 | 10.0 | 105 | 115 | 135 | 190 | 235 | 110 | |

| 16 | 1.21 | 2.0 | 9.0 | 11.5 | 135 | 145 | 175 | 245 | 302 | 138 | |

| 25 | 0.78 | 2.0 | 10.0 | 13.0 | 180 | 195 | 230 | 330 | 402 | 187 | |

| 35 | 0.554 | 2.0 | 11.5 | 14.5 | 225 | 245 | 290 | 410 | 503 | 233 | |

| 50 | 0.386 | 2.2 | 13.0 | 17.0 | 285 | 310 | 370 | 520 | 637 | 295 | |

| 70 | 0.272 | 2.4 | 15.0 | 19.0 | 355 | 385 | 460 | 650 | 794 | 372 | |

| 95 | 0.206 | 2.6 | 17.5 | 21.5 | 430 | 470 | 560 | 790 | 961 | 449 | |

| 120 | 0.161 | 2.8 | 19.5 | 24.0 | 500 | 540 | 650 | 910 | 1118 | 523 | |

| 150 | 0.129 | 3.0 | 21.5 | 26.0 | 580 | 620 | 740 | 1040 | 1297 | 608 | |

| 185 | 0.106 | 3.2 | 23.0 | 29.0 | 660 | 715 | 850 | 1200 | 1476 | 690 | |

| 240 | 0.0801 | 3.4 | 27.0 | 32.0 | 710 | 770 | 916 | 1296 | 1587 | 744 | |

| 300 | 0.0641 | 3.6 | 30.0 | 35.0 | 800 | 850 | 1035 | 1450 | 1790 | 840 | |

| 400 | 0.0486 | 3.8 | 33.0 | 39.0 | 925 | 1000 | 1195 | 1690 | 2070 | 970 | |

| Rating factors for variation in ambient temperature | |||||||||||

| Ambient temperatureC | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 55 | 60 | 65 | |

| Rating Factor | 1.04 | 1.00 | 0.96 | 0.91 | 0.87 | 0.82 | 0.76 | 0.69 | 0.64 | 0.57 | |

Company Details

Focusing on a customer-centric approach, ELECTRO CABLES INDUSTRIES has a pan-India presence and caters to a huge consumer base throughout the country. Buy Wires/Cables & Accessories in bulk from ELECTRO CABLES INDUSTRIES at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

50

Establishment

2009

Working Days

Monday To Sunday

Certification

ISO 9001:2008,ISI Certificate, IS1154:PT1:1998

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Indore, Madhya Pradesh

Accepts only Foreign inquiries

Proprietor

Mr. S. K. Jain

Address

Plot No. 41- B - 42 - 43 - A, Electronic Complex, Pardeshipura, Indore, Madhya Pradesh, 452009, India

copper welding cable in Indore

Report incorrect details