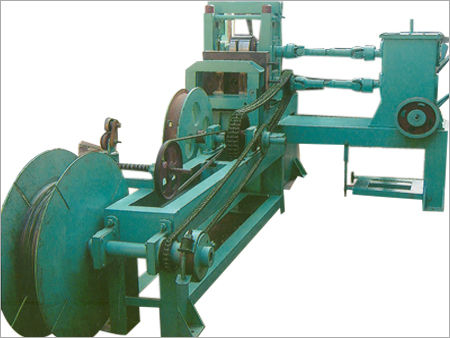

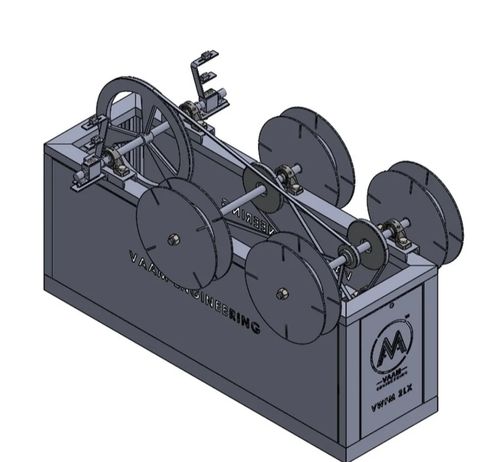

Wire Flattening Machines

Price:

Get Latest Price

In Stock

Product Specifications

| Product Type | Wire Flattening Machines |

| Wire Material | Steel wire |

| Usage | Other, v |

| Color | Multiple |

| Supply Ability | 1 Per Week |

| Delivery Time | 1 Week |

| Sample Policy | Contact us for information regarding our sample policy |

| Packaging Details | Standard packaging |

Product Overview

Key Features

Performance Parameters of Full-Automatic Wire Flattening Machines Manufacturer

(1) Range of input material: 1-5.5 copper round wires.

(2) Number of round wire drawing dies: 1 die/MAX.

(3) Rolling range: Dia.180MM rolls, rolling ratio within 6, (finished product aspect ratio 6/MAX).

(4) Mechanical speed: 350RPM/Max.

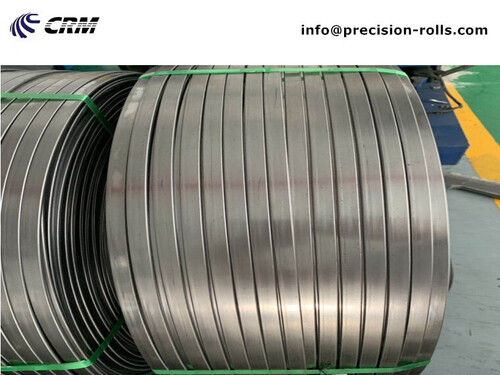

(5) Range of rolled products: width 2-8MM, thickness 1-3MM.

(6) Wire drawing range: the area reduction rate is less than 25%.

(7) Number of rolling mills: 1.

(8) Drawing dies: 1 set for round wire drawing + 2 set for flat wire drawing.

(8) Outer diameter of flat capstan: 750mm, round capstan 600mm.

(9) Die outer diameter: 40MM.

(10) Round drawing machine motor: 4KW deceleration motor and 4KW (sinusoidal) tension type inverter.

(11) motor for rolling mills: 7.5KW AC motor and 7.5KW (sinusoidal) tension type inverter, or 3KW*2 servo + reducer direct drive (sinusoidal) synchronous controller.

(12) Flat wire drawing motor: 5.5KW reducer AC motor and 5.5KW (sine) tension type inverter.

(13) The high wear-resistant tungsten steel material is precisely processed, and the roll hardness is processed by ultra-fine tungsten steel with the highest hardness HRA92.9-93.5 in China. The outer surface roughness is RA=0.012-0.025 microns, and the shaft runout is less than 0.001 mm.

Company Details

Sky Bluer Environmental Technology Co. Ltd is manufacture specialized in precision cold rolling mills and systems for metal shaping, which mainly products includes micro precision rolling mills, micro rolling cassettes, Turk Head,universal rolling mills, and precision rollers. We have independently R&D rectangular spring wire line, flat wire rolling mill, volute spiral spring continuous rolling line, valve spring shaped wire rolling mill, and triangular wire rolling mill to replace brand Europe/USA/Japan cold rolling mills. By the new method of Self-made rolling mill combined with rolling die, our concept will be adjusted to this new method it guarantees for the most cost-saving quality improvement of your products. better quality in evenness and finishing, the straightness up to 0.5mm/m, thickness and width tolerance can be accurate down to within 0.005mm. Active introduction of Brand Japan micro high-precision roll processing and grinding technology, the roundness tolerance is less than 0.001mm., finishing is 0.02 Service Commitment: What we provide is not only precision rolling mills, but also technology and service. We provide users with free-of-charge for profiled wire proofing and hole design.

Business Type

Exporter, Importer, Manufacturer, Distributor, Supplier, Trading Company, Wholesaler, Retailer, Dealer, Fabricator, Producer

Employee Count

80

Establishment

2008

Working Days

Monday To Sunday

Payment Mode

Telegraphic Transfer (T/T)

Related Products

Explore Related Categories

Seller Details

Zhangjiagang, Jiangsu

Sales Engineer

Mr Roller

Members since

5 Years

Address

Huayu Road, Donglai Town, Zhangjiagang City, Jiangsu Province, Zhangjiagang, Jiangsu, 225600, China

wire flattening machine in Zhangjiagang

Report incorrect details