Fasteners

(17780 products)Silver Threaded Fasteners

75 INR (Approx.)/Kilograms

MOQ500 Kilograms/Kilograms

ColorSilver

HardnessHard

GradeIndustrial

Product TypeThreaded Fasteners

Surface TreatmentPolishing

FinishPolish

Hex Bolts Size: Different Available

1000 INR (Approx.)/Piece

MOQ1 , Piece/Pieces

SizeDifferent Available

Surface TreatmentOther

Product TypeHex Bolts

UseIndustrial

Silver Coil Spring Pin

Price: 15 INR/Piece

MOQ1000 Piece/Pieces

Product TypeCoil Spring Pin

UsageIndustrial

ColorSilver

Size1/32-3/4"

MaterialStainless Steel

Spring India

Mumbai

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller25 Years

Stainless Steel Industrial High Tensile Fasteners

Price Trend: 100-1000 INR/Unit

MOQ500 Unit/Units

UsageIndustrial, Automobile

Product TypeHigh Tensile Fasteners

Surface TreatmentPolishing

MaterialStainless Steel

Full Threaded Rods By Niko Steel and Engineering Llp

Price Trend: 160.00 - 190.00 INR/, Kilograms

MOQ20 , Kilograms/Kilograms

Payment TermsCash Against Delivery (CAD), Cash on Delivery (COD), Letter of Credit (L/C), Cash in Advance (CID), Cheque, Cash Advance (CA)

Supply Ability1 Per Day

Delivery Time1 Days

Niko Steel And Engineering Llp

Mumbai

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller22 Years

Metal Brass Fasteners

Price: 5000 INR/Number

MOQ1 Number

Product TypeBrass Fasteners

Metal TypeOther

UsageIndustrial, Engineering, Manufacturing, Fitting, Furniture, Electronics, Electrical, Compass, Watches, Gears, Valves, Bearings, Plumbing, Marine Industry, etc.

MaterialMetal

Jayant Impex Pvt Ltd

Mumbai

Trusted Seller

Trusted Seller4 Years

Super Premium

Super PremiumCa104 Aluminum Bronze Fasteners Application: All Fittings

Price: 150.00 INR/Kilograms

MOQ10 Kilograms/Kilograms

Surface TreatmentPowder Coated

GradeCA 104 , NES 833 , C63000 ETC

ColorGolden

MaterialAluminum

ApplicationAll fittings

Govind Metal Co.

Ahmedabad

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller17 Years

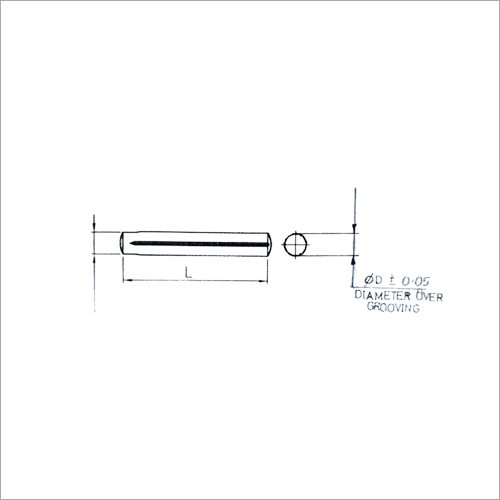

Grooved Dowel Pin - Application: Industrial

Price: 10 INR/Piece

MOQ1000 Piece/Pieces

ColorGray

Surface TreatmentGalvanized

Grade316,SS 304,316 L

UsageConstruction

Product TypeFastener

MaterialSteel

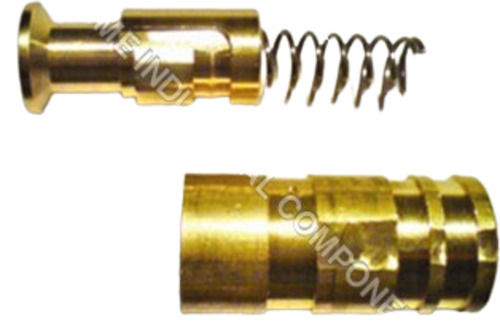

Brass Spring Anchors Capacity: 1-5 Ton/Day

Price Trend: 20.00 - 200.00 INR/Piece

MOQ1000 Piece/Pieces

ColorGolden

Capacity1-5 Ton/day

GradeA

Surface TreatmentPolishing

MaterialBrass

Prime Industrial Components Llp

Jamnagar

Trusted Seller

Trusted Seller19 Years

Super Seller

Super Seller3031500 Flattener With Hand Protection - Color: Black

MOQ100 Unit/Units

UsageIndustrial

ShapeRound

LengthDifferent Size Inch (in)

ColorBlack

SizeDifferent Size

Head TypeRound

Obo Bettermann India Pvt. Ltd.

Chennai

Trusted Seller

Trusted Seller1 Years

Super Seller

Super SellerTrustweld Shear Stud Insert Plates

Price: 12000.0 INR/Ton

MOQ1 Ton/Tons

Main Export Market(s)[, ]

Main Domestic Market], [

Trustweld Engineers India Pvt Ltd

Pune

Dark Grey Blanking Plugs

Price: 3.00 INR/Unit

MOQ1 Unit/Units,

UsageElectrical enclosures, panels, junction box.

ColorDark Grey, Light Grey, Black.

GradeNylon.

Surface TreatmentOther

MaterialPlastic

Silver Anchor Rail Fasteners

Price: 25 INR/Piece

MOQ100 Piece/Pieces

StandardHigh

ColorSilver

Head TypeRound

Size22 Mm

Product TypeAnchor Rail Fasteners

GradeA

Radhe Krishna Industries

Rajkot

Trusted Seller

Trusted Seller3 Years

Premium Seller

Premium SellerNIPPEN Fasteners

Product DescriptionOur company is well versed in manufacturing, supplying and exporting a top of the line range of Fasteners in Mumbai, Maharashtra, India. Our Fasteners is made from supreme quality material and modern technology for best long lasting fastening jobs

Xylan Coated Fasteners - Steel, 6-100 mm Diameter | Hexagonal Head, Corrosion Resistant, Accurate Dimensions, Durable Finish

Price: 5 INR/Unit

MOQ10000 Unit/Units

Product TypeXylan Coated Fasteners

Head TypeHexagonal

Surface TreatmentPowder Coated

Diameter6-100 Millimeter (mm)

GradeIndustrial

ColorMultiple

Ss Multi Grip Blind Rivet Application: Industrial

Price Trend: 2.00 - 5.00 INR/Piece

MOQ1000 Piece/Pieces

Product TypeMulti Grip Rivets

ColorGray

UsageConstruction

Surface TreatmentPowder Coated

MaterialStainless Steel

ApplicationIndustrial

Ketan Engineering Co

Mumbai

Trusted Seller

Trusted Seller13 Years

Super Seller

Super SellerMetal Screws

Price Trend: 10.00 - 60.00 INR/Piece

MOQ1000 , Piece/Pieces

Supply Ability1 Per Month

Delivery Time1 Week

Unique Industrials

Secunderabad

Trusted Seller

Trusted Seller10 Years

Super Seller

Super SellerGolden Brass Stainless Steel Inserts

Price: 20 INR/Piece

MOQ500 Piece/Pieces

Product TypeBrass & Stainless Steel Inserts

UsageIndustrial

Surface TreatmentPolishing

SizeCustomize

ColorGolden

MaterialOther, Brass & Stainless Steel

Vinay Engineering Company

Vasai

Trusted Seller

Trusted Seller8 Years

Premium Seller

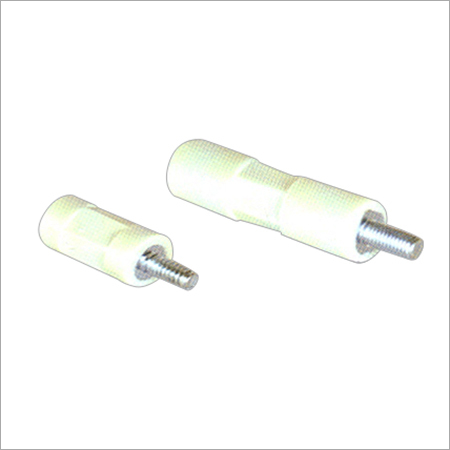

Premium SellerPBT Insulated Spacer

Price: 150 INR/Piece

MOQ500 Piece/Pieces

Supply Ability5000 Per Month

Delivery Time10-25 Days

Flucon Components Pvt Ltd

Thane

Trusted Seller

Trusted Seller17 Years

Premium Seller

Premium SellerInconel Nuts And Bolt Application: Pipe Fitting

Price: 20 INR/Piece

MOQ10 Piece/Pieces

FeatureGood Quality

UsageIndustrial

Grade304

FinishPolish

ColorSilver

HardnessHard

Shree Rajlaxmi Forge

Mumbai

Trusted Seller

Trusted Seller7 Years

Super Seller

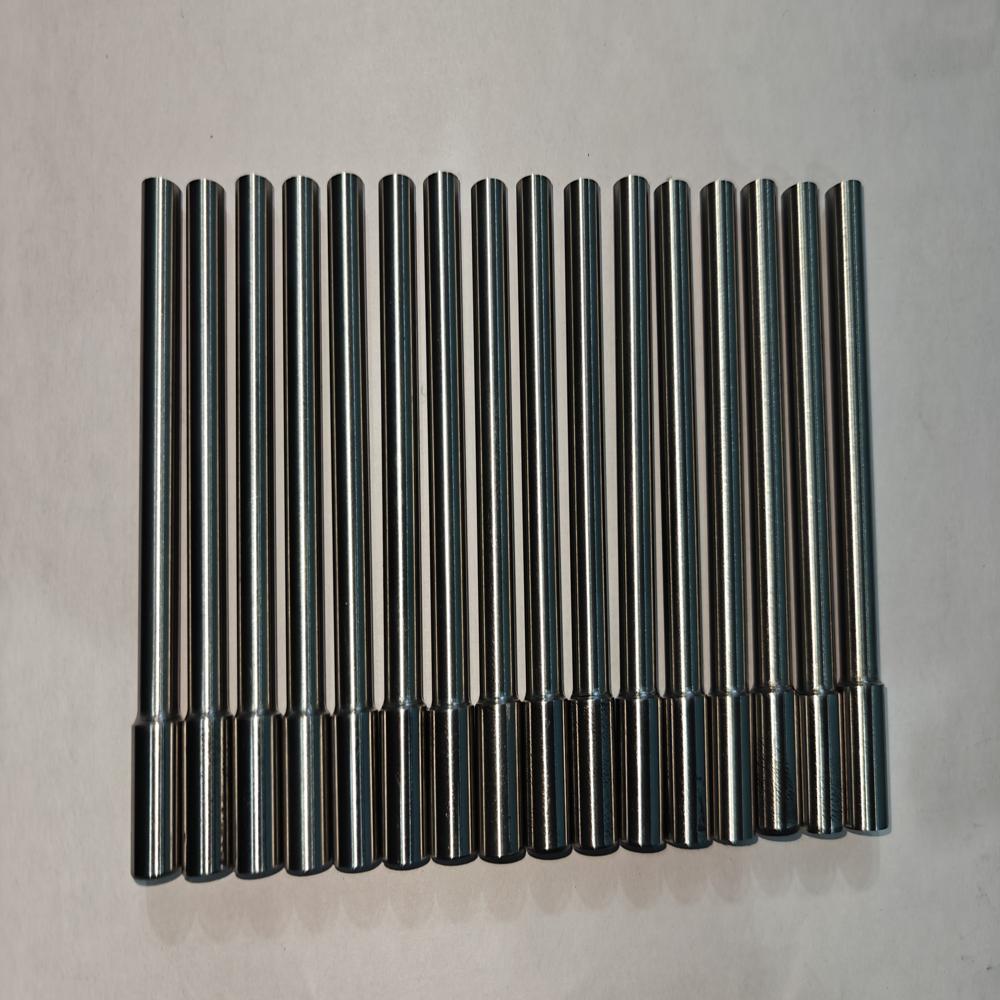

Super SellerBig Bucket Pin Application: Industrial

Price: 1800 INR/Piece

MOQ10 Piece/Pieces

SizeDifferent Available

Surface TreatmentPolishing

GradeDifferent Available

MaterialSteel

ApplicationIndustrial

Shree Adarsh Enterprises

Indore

Trusted Seller

Trusted Seller4 Years

Premium Seller

Premium SellerTitanium Fasteners Grade: Gr.2/Gr.5 And Gr.7

Price: 250 INR/, Kilograms

MOQ500 , Kilograms/Kilograms

Product TypeFasteners

Size2 mm to 30 mm

ColorSilver

GradeGr.2/Gr.5 and Gr.7

MaterialOther

Nascent Pipes & Tubes

Mumbai

Trusted Seller

Trusted Seller11 Years

Super Seller

Super SellerMale Threaded Adaptor - High-Quality 319 Type Material, Sizes 1/2" to 2", Customizable Threading Options

Product DescriptionThe Male Threaded Adaptor provide by us are manufactured, exported & supplied from Jamnagar, Gujarat, India. These are made form excellent quality of raw material which ensure durability at its user end. These Male Threaded Adaptor are acclaimed by large number of customer. These products are availa

Bhargav Brass Industries

Jamnagar

Trusted Seller

Trusted Seller14 Years

Premium Seller

Premium SellerCopper Hollow Rivet Application: Contruction/Electrical

Price: 850 INR/Kilograms

MOQ100 Kilograms/Kilograms

Product TypeCOPPER

GradeELECTROLYTIC

Head TypeROUND/FLAT/SNAP/UNIVERSAL

Capacity250 Kg/day

Diameter1-12 Millimeter (mm)

Length1-120 Millimeter (mm)

Rajesh Rivet Industries

Mumbai

Super Seller

Super SellerSilver Corrosion Resistant Weatherproof Hexagonal Reducer

Price: 88 INR/Piece

MOQ100 Piece/Pieces

UsageHardware Fitting

GradeA

ColorSilver

Product TypeHexagonal Weather Proof Reducer

Surface TreatmentNickel Plating

Head TypeHexagonal

Metal Craft Industries

Rajkot

Trusted Seller

Trusted Seller6 Years

Super Seller

Super SellerIndustrial Fasteners Application: Fitting

Price: 20.00 INR/Piece

MOQ100 Piece/Pieces

UsageIndustrial

GradeA

ColorMetallic

Capacity280 Kg/hr

HardnessHard

Surface TreatmentPolishing

Allied Power Solutions

Delhi

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller14 Years

Silver Net Hooks

Price: 12 INR/Piece

MOQ100 Piece/Pieces

ColorSilver

Surface TreatmentPolishing

GradeA

UsageIndustrial

FeatureGood Quality

FinishPolish

Narayan Engg. Co.

Mira Bhayandar

Trusted Seller

Trusted Seller10 Years

Super Seller

Super SellerDrywall Screw Application: Industrial

MOQ100 Kilograms/Kilograms

UsageIndustrial

ColorGray

Product TypeDrywall Screw

Surface TreatmentPowder Coated

MaterialSteel

ApplicationIndustrial

Polished Mild Steel Point Coil Nails

Price: 3600 INR/Carton

MOQ50 Carton/Cartons

ColorGolden

Surface TreatmentPolishing

Head TypeRound

UsageUsed to fastening two objects

Product TypePoint Coil Nails

Size1/2 Inch

Rudani Enterprises Pvt. Ltd.

Nashik

Trusted Seller

Trusted Seller8 Years

Super Seller

Super SellerMild Steel Riveting Machine, Material: Mild Steel

Product DescriptionMild Steel Riveting Machine

Prateek International

Faridabad

Trusted Seller

Trusted Seller7 Years

Premium Seller

Premium SellerLatest From Fasteners

Pin Type Anchor Fasteners

By:

V S Traders

All Types Of Fasteners

By:

Front Line Fire Services

Fasteners Manufacturer in India

By:

Mahadev Steel India

Anchor Fasteners

By:

M/s Shubh - Labh

RAA4-9-6 Aluminum Right Angle Fasteners

By:

Aar Industrial Supplies And Solutions India

Ready To Ship Fasteners

Fasteners

The majority of today's machinery is composed of a number of individual components that, when put together, form a whole that is fully functional. On the other hand, these components of the machine often produce enormous forces and are subject to vibrations that are sufficient enough to cause the parts to become disassembled and the machine to fail. The use of fasteners, which are crucial parts of hardware, helps to reduce this difficulty by attaching two or more components together in a single assembly. Fasteners, on the other hand, are available in a wide variety of types, and each of those types is best suited to a particular set of uses.

Types of Fasteners and How to Choose Them

The term "fastener" refers to any piece of hardware that can be used to join two or more separate components together in a mechanized manner. There are many different kinds of fasteners, which are typically made of metal and can be broadly categorized as either permanent or temporary fasteners. Permanent fasteners are designed to create a joint between two components that are intended to be there permanently. These devices are single-use, which means that you can only use them once due to the fact that removing these fasteners would destroy them. Temporary fasteners, on the other hand, provide simple removal and reuse while providing a level of strength that is equivalent to that of permanent fasteners or even superior. The following are the five most common types of fasteners:

Screws: A screw is a type of temporary fastener that consists of a head and shank that both have threads that are extremely sharp. To use a screw to link two components together, you would first need to insert the screw into the pieces using a screwdriver. After that, you could then attach the two parts together.

Bolts: External threads, also known as male threads, begin at the tips of bolts, just as they do with screws. Bolts have a structure that is comparable to that screws. However, in contrast to screws, bolts do not have a self-threading feature (they do not cut threads into the material). Instead, in order to engage and establish mechanical connections, they need prepared pieces (like nuts) and pre-tapped holes. The most common kinds of bolts are detailed in the following list.

Nuts: A threaded hole, also known as female threads, is located in a nut, which is a kind of fastener that is normally used in conjunction with a matching bolt to create a bolted connection. The ability to build large machines while yet benefiting from the great strength and simplicity of installation offered by nuts and bolts is a significant advantage offered by employing these types of fasteners (and removal).

Washers: Washers are metal discs that are circular in shape and are used in combination with nuts and bolts. They contribute to the reduction of friction and provide an equal distribution of load from nuts and bolts on the portion that is being secured. Plain washers and spring washers are the two kinds of washers that are available. The form of a plain washer is a disc with a hole in the center. These washers are also referred to as flat washers. They are the form of washer that is used the most often, particularly in situations where the sole need is to guarantee that nuts and bolts on components have an equal distribution of load.

Rivets: Permanent fasteners known as rivets have a shaft that is designed to be put into pre-existing holes in order to bind two or more components together. When you enter a rivet into the parts that you wish to put together, it will generate a permanent head at the other end, which will prevent the rivet from being removed.

How Fasteners Are Made

Although fasteners may be found in a dizzying array of sizes and contours, the fundamental manufacturing process is, for the most part, the same across the board. First, the steel wire is cold-forged into the desired form, then it is heat-treated to enhance its strength, and last, it is surface-treated to improve its durability, and only then is it packaged and ready for shipping. On the other hand, the manufacturing process may need a greater number of extra processes in order to accommodate more complex bolt designs:

1. The process of cold forging begins with the uncoiling and subsequent cutting to the desired length of massive steel wire rods. The grade of steel used in all products manufactured in the industry is standardized in accordance with the standards of ISO 898-1. After that, the wire is cold-forged into the desired form by using specialized equipment. In this process, the steel is shaped while it is still at room temperature by passing it through a sequence of dies while the pressure is turned up to a high level. The actual tooling may be rather complicated; it may consist of up to 200 separate pieces, each of which must adhere to tolerances that are measured in hundredths of a millimeter. Cold forging, once the technique has been developed, enables bolts may be manufactured fast, in huge numbers, and with a high degree of homogeneity.

2. The act of subjecting the bolt to temperatures so high that the steel is caused to become more brittle is known as heat treatment, and it is a routine procedure for all types of fasteners. When the steel is softer, cutting or rolling are often used to apply to the thread prior to heat treatment. The process of rolling is quite similar to that of cold forging; it entails passing the bolt through a die in order to form and shape the steel into threads. Threads are formed by the process of cutting and extracting steel from the material.

Factors that Can Affect Fasteners Working

Some of the things that may have an effect on how well fasteners operate are as follows:

What is the purpose of using the fastener? The first thing that should be thought about is the purpose that both the fastener and the product itself will serve. For instance, if the fastener is opened and closed often, it would make sense to choose a solid metal fastener that is both sturdy and reliable. If a fastener is opened very seldom, if at all, a less expensive option, such as plastic, could be appropriate.

Where is the fastener being used? The kind of fastener that your product could require is determined in part by environmental considerations. It is possible for fasteners that are used inside in settings that are not demanding to be less resistant than those that are used outside or in an environment that is harsher. Consider additionally special environmental needs.

How do I determine which type of fastener I need? You are aware that there are many different kinds of fasteners available, and that each type of fastener has several different variants within itself. For instance, you have the option of selecting screw heads with a variety of various shapes and designs. There are many different kinds of nuts, such as hex nuts, cap nuts, acorn nuts, jam nuts, flange nuts, square nuts, tee nuts, torque locks, k-locks, slotted nuts, connection nuts, and castle nuts.

Which type of material should I use? You should also be able to choose the appropriate material for your fasteners with the assistance of knowing how and where the fastener will be utilized. The choice of material has an effect not only on the cost of the fastener but also on its resistance to corrosion and its level of strength.

Which type of coating is appropriate? Coatings are frequently applied to fasteners in order to increase their resistance to corrosion. However, in some instances, coatings serve no purpose other than to add aesthetic value.

What is the appropriate measurement? The size of the fastener is also determined by the manner in which it is utilized as well as the environment in which it is used. Applications that demand a heavier load may call for bigger fasteners, while designs that are more compact may call for smaller ones.

What is fastener and when to use them?

A mechanical connection between two or more things may be made with fasteners, and this connection can be made either permanently or temporarily. There is a wide variety of distinct kinds of fasteners, each serving a particular function. Due to the simplicity with which they may be inserted and removed as necessary, threaded fasteners are among the most widely utilized when it comes to the process of putting components together. Bolts, screws, and studs are the three primary kinds of threaded fasteners that are often used. When clamping two or more pieces together, nuts and bolts are often used in combination with one another. The hexagonal nut is the most common sort of nut, although there are many other varieties of nuts that may be used for a variety of purposes. It is usual practice to place a washer between the head of a bolt, screw, or nut and the material that is being clamped by the fastener. Rivets are a kind of permanent fastening, meaning that once they have been removed from their position, they cannot be used again. Rivets have a wide variety of uses and businesses that make use of them, but the most prevalent usage is in the joining of metal sheets and plates.

Buy Fasteners Online

Purchasing fasteners in bulk quantity is very convenient with the availability of a number of fasteners manufacturers in India. Buyers can connect with the fastener manufacturers and fastener suppliers, Washers suppliers, etc.. Interested buyers may also check other available sub-categories including:

- MS Bolt

- Brass Bolts

- Cap Head Bolt

- Custom Hex Head Bolts

- Titanium Fasteners

- Stainless Steel Bolts

- Quick Release Fasteners

- Roofing Screw

- Ball Screws & Lead Screws

Buyers can contact suppliers and send their purchasing needs of different types of fasteners.

FAQs: Fasteners

Q. Why fasteners are so commonly used?

Ans. Fasteners are widely used hardware product in almost every walk of life. Everywhere people come across machines, equipment, devices, apparatus and appliances which all use one or the other types of fastener.

Q. What is a hex nut?

Ans. A hex or hexagonal nut has a hexagonal-shaped construction whit female thread inside. The nuts are fastened with a corresponding-sized wrench to a bolt.

Q. What are the materials in which fasteners are made?

Ans. Fasteners are made in different types of materials, such as steel, nickel, aluminium, brass, titanium, iron and alloy steel among others.

Q. Where can buyers find trusted manufacturers of fasteners?

Ans. Buyers can check out B2B portals to get a list of fastener manufacturers and place their purchasing requirements.

Q. What is the advantage of a screw over a nail?

Ans. Screws have firm holding capacity than nails. In addition, screws can be easily removed by unscrewing and can be reused but this is not the case with nails. Technically nails become dysfunctional when removed while screws can be fixed on the same slot once again.

Q. What are examples of fasteners?

Ans. Some examples of fasteners are nuts, bolts, rivets, washers, etc.

Q. What is the difference between fasteners and bolts?

Ans. A bolt is a fastener with really no tapered end that is frequently used in combination with washers and nuts. A screw is a kind of tapered fastener that either fits into an already existing thread in a material or, as it rotates, makes its own thread in the material.

Q. What is another word for a fastener?

Ans. A few different words for fasteners are screws, clasps, buckles, bolts, etc.

Q. What is the most common fastener?

Ans. Fasteners come in a variety of forms, the most common of which is the bolt. These mechanical components are often used to join two unthreaded parts. On one end of a bolt is a hexagonal head, and the other end of the bolt has external male threads. On the opposite end of the bolt, there is typically a nut that is used to secure it.

Related Topic:

Top 10 Fasteners Manufacturers, Suppliers & Exporters in India

Manufacturers & Suppliers of Fasteners

Company Name | Member Since |

|---|---|

Spring India Mumbai, India | 25 Years |

Niko Steel And Engineering Llp Mumbai, India | 22 Years |

Prime Industrial Components Llp Jamnagar, India | 19 Years |

Govind Metal Co. Ahmedabad, India | 17 Years |

Flucon Components Pvt Ltd Thane, India | 17 Years |

Vsm Plast Pune, India | 16 Years |

Bhargav Brass Industries Jamnagar, India | 14 Years |

Allied Power Solutions Delhi, India | 14 Years |

Neeta Enterprises Mumbai, India | 13 Years |

Ketan Engineering Co Mumbai, India | 13 Years |

Popular Products