CNC Machines

(9877 products)Black Special Purpose Router

MOQ1 Piece/Pieces

Product TypeSpecial Purpose Router

General UseIndustrial

MaterialMetal

Power SourceElectric

Dimension (L*W*H)1.27 A--1.27, 1.3A--2.5, 1.5A--3.0 Millimeter (mm)

ColorBlack

Angel India Cad Cam Pvt.ltd.

New Delhi

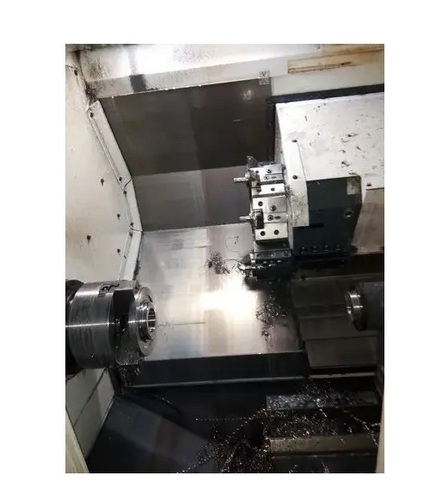

Slant Bed Turn Mill Centre - Feature: Low Energy Consumption

Price: 50000.00 INR/Unit

MOQ1 Unit/Units

General UseIndustrial

MaterialMetal

AutomaticYes

Power SourceElectric

MotorAC Motor

FeatureLow Energy Consumption

Didac International

New Delhi

Trusted Seller

Trusted Seller11 Years

Tcp-V-500 (3 Axis) Cnc Drilling Machine - Color: White

Price: 76500 INR/Unit

MOQ1 Unit/Units

ColorWhite

General UseIndustrial

MaterialStainless Steel

ComputerizedNo

AutomaticYes

Power SourceElectric

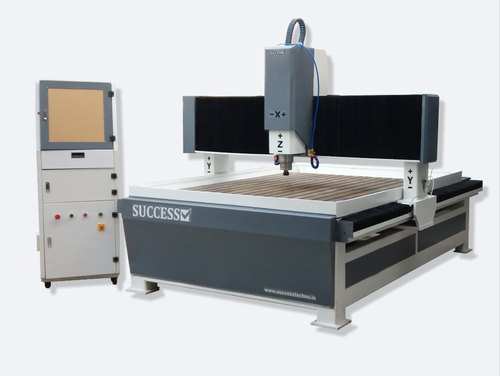

Cnc Stone Router Machine - Feature: Low Energy Consumption

Price: 600000 INR/Unit

MOQ1 Unit/Units

Product TypeCNC Stone Router Machine

General UseIndustrial

MaterialStainless Steel

ComputerizedNo

AutomaticYes

Power SourceElectric

High Precision Cnc Facing Centring Drilling And Tapping Spm For Round Bar

Price: 16000000 INR/Piece

MOQ1 Number

ColorOther

Product TypeCNC Facing And Centring SPM

MaterialMetal

TypeHorizontal

Weight (kg)10 Tonne

AutomaticYes

Cnc Water Cutting Machine

Product DescriptionTECHNICAL SPECIFICATION OF Cnc Water Cutting Machine\015\012- DWJ46126-BB CNC x-y cutting table \015\012- Structure: Bridge Structure\015\012- Cutting table size (XxY): 4600mmx12600mm\015\012- Travel of X axis: 4600mm\015\012- Travel of Y axis: 12600mm\015\012- Travel of Z axis: 210 mm / 310mm\015

CNC Wirecut Machine - Reusable Molybdenum Wire, 1200x900x1300mm | High Speed, Low Maintenance, Automatic Centering, Fine Surface Quality, Multi-Pass Capability

Price Trend: 730538.00 - 3017437.00 INR/Set

MOQ1 Set/Sets

Product TypeCNC WIRECUT

Materiala, [, ', M, e, t, l, ', ]

Type[, ', V, e, r, t, i, c, a, l, ', ,, , ', H, o, r, i, z, o, n, t, a, l, ', ]

Weight (kg)800-8500 Kilograms (kg)

Computerized[, ', Y, e, s, ', ]

Automatic[, ', Y, e, s, ', ]

CNC Pattern Router Machine

Price: 3500000.00 INR/Piece

MOQ1 Piece/Pieces

ColorGreen

Product TypeCNC PATTERN ROUTER

MaterialAluminum

TypeOther

Weight (kg)4500 Kilograms (kg)

ComputerizedYes

CNC Engraving Machine

Price Trend: 1400000.00 - 1600000.00 INR/Unit

MOQ01 Unit/Units

Supply Ability05 Per Week

Delivery Time3-5 Days

Main Domestic MarketAll India

Automatic Cnc Stone Engraving Machine

Price: 550000 INR/Unit

MOQ1 Unit/Units

ColorWhite

Product TypeLaser Engraving Machines

Laser TypeCO2

ComputerizedNo

Automatic GradeAutomatic

Cnc Synchronize Press Brake Machines Industrial

MOQ1 Piece/Pieces

Product TypeCNC Synchronize Press Brake Machines

General UseIndustrial

MaterialStainless Steel

AutomaticYes

Power SourceHydraulic

Weldor Engineering Pvt. Ltd.

Rajkot

Gray Cnc Stone Engraving Router Machine

Price: 750000 INR/Unit

MOQ1 Unit/Units

ColorGray

Product TypeCNC Stone Engraving Router Machine

General UseIndustrial

MaterialMetal

TypeCNC Router

ComputerizedNo

CNC Internal Grinding Machine - Height 150 / 200 mm, Speed Range 20 - 650 rpm | Rapid Feed 7000 mm/min, Work Head 4 / 5 MT

Product TypeCNC Internal Grinding Machine

CNC Drilling Machine - 4000x4000x2000 mm, Gray Color | High Speed, Low Energy Consumption, Automatic Operation, BTA Drilling for Metal Applications

Product TypeCNC Four Spindle Gun Drilling Deep Hole Drilling Machine

General UseCNC Four Spindle Gun Drilling

MaterialMetal

Weight (kg)6000 Kilograms (kg)

AutomaticYes

Power SourceElectric

CNC Controllers - Compact Digital CNC System with Delta Tau Pmac2 Technology, 5-Axis Universal Motion Control, Embedded PC104 Computer, Flat-Screen Front Panel, Programmable F-Keys and Keyboard

Product DescriptionWe are offering a wide range of CNC Controllers, These have optical encoder or scale feedback operation and are a compact, low cost, computerized numerical control for metal cutting machine tools and other equipment requiring positioning and contouring axes.\015\012\015\012\015\012CNC Systems (Advan

Lakshmi Electro Controls & Automation

Bengaluru

CNC Bending Machine - For 0.5mm-25mm Carbon Steel, 0.5mm-20mm Stainless Steel, Precision Cutting Capability, Versatile Metal Processing

Price: 12000 USD ($)/Case

MOQ1 Number

Product DescriptionCNC Bending Machine

Single Head Outer Assembly - General Use: Industrial

Price: 945000 INR/Unit

MOQ1 Unit/Units

General UseIndustrial

MaterialStainless Steel

ComputerizedNo

AutomaticYes

Power SourceElectric

Mahale Automations Private Limited

Pune

Trusted Seller

Trusted Seller3 Years

CNC Wire Cutting EDM Machine - High Speed & Medium Speed Options for Customized Workpiece Thickness and Precision | Tailored for Taper Needs, High Accuracy

Product DescriptionCNC wire cutting edm for workpiece producing, you can choose high speed wire cut machine or middle speed wire cut machine. So machine type we can provide, as your taper need, workpiece thickness. Accuracy

Taizhou Winstrong Special Net Co., Ltd.

Taizhou

Rear Cylinder Cnc Hydraulics Press Brake

Product DescriptionRear cylinder CNC hydraulics press brake\015\012Standard Features\015\012\302\267Purvaj manual quick clamp and standard tooling set\015\012\302\267Front sheets support Arms\015\012\302\267Stroke depth measurement through high precision linear scales\015\012\302\267CNC CONTROLLER \342\200\223Cybelec

CNC Press Brake Machine - Stainless Steel, Fully Automatic, Cream and Black | Electric Powered, One-Year Warranty, Ideal for Metalworking

Price: 1700000 INR/Piece

MOQ1 Piece/Pieces

ColorOther, Cream And Black

Product TypeCnc Press Brake Machine

MaterialStainless Steel

ComputerizedNo

AutomaticYes

Power SourceElectric

Technex Machines (india) Llp

Rajkot

Numerical Control Pipe End Beveling Machine (Top and bottom Asynchronous Clamping)

Product DescriptionWe are a leading Exporter, Manufacturer & Supplier of Numerical Control Pipe End Beveling Machine (Top and bottom Asynchronous Clamping). We are based in Shanghai, China. \015\012\015\012Performance Features: asynchronously clamping with bottom screw lifter and top hydraulic cylinder; radial differ

Shanghai Qianshan Piping Technology Co., Ltd.

Shanghai

Industrial CNC Router Machine - Metal Compatible, 1300x2500x200mm Working Area | High Speed Operation, Automatic Tool Changer, Multi-Axis Movement

MOQ1 Unit/Units

Product TypeIndustrial CNC Router Machine

General UseIndustrial

MaterialMetal

AutomaticYes

Power SourceElectric

FeatureHigh Speed

White Cnc Fiber Laser Machine

Price: 3500000 INR/Piece

MOQ1 Piece/Pieces, Piece/Pieces, Piece/Pieces

ColorWhite

Product Typecnc

MaterialMetal

TypeHorizontal, CNC Router, Other

Weight (kg)4000 Kilograms (kg)

ComputerizedYes

Mini Cnc Metal Engraving Machine Industrial

Price: 625000 INR/Unit

MOQ10 Unit/Units

Product TypeMini CNC Metal Engraving Machine

General UseIndustrial

MaterialStainless Steel

ComputerizedNo

AutomaticYes

Power SourceElectric

Multiple Thread CNC Machining Center - Metal, 11 kW Power, 8000 RPM Spindle Speed | High Rigidity, Automatic PLC Control, Reliable and Accurate Performance

Price: 236444.00 USD ($)/Set

MOQ1 Set/Sets

Product TypeZMC-3000

MaterialMetal

ComputerizedYes

AutomaticYes

PLC ControlYes

Power SourceElectric

P-one Machinery Co., Ltd.

Taichung

Premium Seller

Premium Seller4 Years

Industrial Cnc Stone Router Machine Capacity: 500 M3/Hr

Price: 350000 INR/Unit

MOQ1 Unit/Units

ColorWhite

Product TypeRouter Machine

General UseIndustrial

MaterialMetal

Capacity500 m3/hr

Weight (kg)1600 Kilograms (kg)

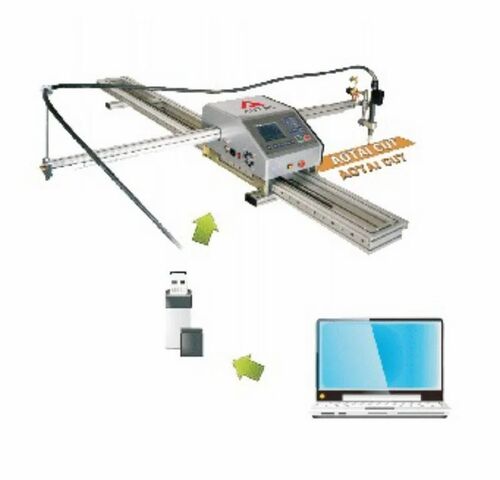

Cnc Profile Cutting Machine - Feature: Low Energy Consumption

Price: 950000 INR/Unit

MOQ1 Unit/Units

Product TypeCNC Cutting Machine

General UseIndustrial

MaterialMetal

AutomaticYes

PLC ControlYes

Power SourceElectric

Ycm Vmc Machine - General Use: Industrial

Price: 68500000 INR/Piece

MOQ1 Piece/Pieces

Product TypeYCM VMC Machine

General UseIndustrial

MaterialStainless Steel

ComputerizedNo

AutomaticYes

Power SourceElectric

Latest From Cnc Machines

CNC Machines Repair & Maintenance

By:

M/s Biswas Trading

Conventional CNC Machines

By:

Bluecon Llc Fz

Cnc Machines Lathe Machine

By:

Quality Machinery Suppliers

Cnc Machines Lathe Mac

By:

Kabir Foundry Works

Cnc Machines

By:

R.s. Technology

Cnc Machines For Industrial Applications Use

By:

Axis India

router machines

By:

Sai C N C Router

Stainless Steel CNC 2D Wire Bending Machine

By:

Auto Link Technology Co., Ltd.

Ready To Ship Cnc Machines

CNC Machine: Introduction

CNC stands for "computer numerical control," and CNC machining is defined as a subtractive manufacturing method that commonly employs computerised controls and industrial machinery to eliminate material layers from a stock piece, referred as the blank or workpiece, to generate a custom designed item.

Several industries can benefit from this technology, including those that require tighter tolerances, such as those involved in aerospace manufacturing, telecommunications, and large-scale CNC machining.

Both CNC machines and CNC machining are right in their own ways, but there is a crucial difference between the two. CNC machines, or computer numerical control machines, are programmable machines capable of doing CNC machining tasks automatically with little to no human interaction.

Definition & Types of CNC Machine:

CNC machining is defined as a subtractive manufacturing method that uses computer numerical control (CNC) machines to remove material layer by layer from a stock piece (the blank or workpiece) to create an end product to exact specifications. Different types of CNC machines.

1. Pick and place CNC machine

Computers, tablets, mobile phones, and other electronic devices are typically built with the help of the CNC Machines of this particular type. It is made up of a number of nozzles that are able to pick up the electrical components and deposit them somewhere else according to the requirements of the person operating it.

In a similar manner, it is also capable of performing the pick and place procedure for additional components.

2. CNC Electrical Discharge Machine

Electrical Discharge Machining, or EDM for short, is used to cut harder materials, and this particular type of EDM has a high MRR Material Removal Rate. For a proper grasp of CNC EDM, a familiarity with conventional electrical discharge machining is necessary.

CNC EDM, or electrical discharge machining, is a type of CNC machine that employs sparks to erode the surface of a workpiece.

The component is installed in the section of the circuit that connects the anode (the work table) and the cathode the tool electrode. When the power is turned up too high, the dielectric fluid ionises, and the power is passed through the fluid to the workpiece, where it dissolves the material. This happens when the power is set up too high.

Parts made using a CNC machine have a superior surface polish to those made on conventional machines since the entire process is automated by a computer programme.

3. CNC Computer Numerical Control

It was one of the pieces of equipment that helped companies across the board produce components more quickly and was utilised extensively.

In this instance, the software is written by a group of engineers, and after it is complete, it can be saved in the memory unit of the system. Once you have uploaded the code to the CNC machine unit for the repeating purpose, there is no need to update it once you have done so.

It is necessary to have a semi-skilled operator in order to run the working of the lathe machine.

4. CNC Milling Machine

Milling machines typically have anything from three to six axes in their arrangement. Components are going to be machined with the assistance of a Multi-point Milling Cutter on this particular machine. This machine is used to produce holes, generate bores, and also create slots in the workpiece. It can also find its application in the construction of Spur gears.

This machine is employed. When it comes to the CNC Milling Machine, Need to build a part programme that takes the form of G Codes and M Codes, and then need to insert that part programme into the brain of the CNC Machine.

It is able to carry out its operations in accordance with the task allotment in the programme in relation to the coordinates.

When compared to traditional milling machines, the CNC Milling machine has a productivity level that is far higher than its counterparts.

5. CNC Laser Cutting Machine

The process of cutting, which is referred to as "Laser Cutting," is carried out with the assistance of a laser, as the name suggests. When performed on a computer numerically controlled machine, this process is referred to as CNC Laser Cutting Machine.

In most cases, it is utilised in the cutting of metal sheets. They are meant to cut through the tougher materials, and the process is very similar to plasma cutting, with the exception that a plasma torch is used to cut through the materials rather than a laser torch.

6. CNC Plasma Cutting Machine

Plasma cutting machines may cut through materials in a manner that is analogous to that of CNC laser cutting machines. They make use of a plasma torch in order to cut through the most difficult materials, as this is not achievable with laser cutting equipment. The plasma has a temperature that is far higher than 20,000 degrees Celsius.

Main Parts of CNC Machine:

The parts of a CNC machine are as follows.

1. Memory Controlled Unit

The MCU functions similarly to the human brain by receiving data from the various inputs, processing that data, and then implementing its conclusions through the various outputs of the CNC machine.

Since the machine only understands the binary system of information, the MCU must include a component known as an arithmetic logic unit to transform the decimal system into the binary system and back again as needed (ALU).

2. Mini computer

The programme will be entered into the minicomputer via keyboard and stored in the minicomputer's memory as software. The above code ensures that the procedure may be carried out without any input from the operator, and with great dimensional accuracy to boot.

3. Drive unit

It is the apparatus that facilitates the transformation of electrical energy into the kind of mechanical energy that is necessary for moving along the axis. When performing CNC Machining, make use of Servo Motors as the drive unit.

4. Feedback Devices

A Displacement Measuring Device measures the actual distance travelled by the Axis and feeds that information back to the MCU, which then compares that distance with the target distance to calculate the displacement.

The number of pulses will be determined by the MCU and transmitted to the drive unit. This process repeats itself in a cycle.

5. Very Few Manual Controls

Manual controls refer to the actions, such as turning the machine on and off, loading and unloading the workpiece, etc., that are required even though the CNC machine has the aforementioned components.

Applications of CNC Machine:

Here are some applications of CNC machines .

i. When compared to traditional machines like milling, grinding, drilling, and turning, the primary advantage of utilising a machine that is controlled by a computer numerically is the greater precision with which metal can be removed. This is a fundamental benefit of employing a CNC machine.

ii. It is used for prototyping by many different components in the world of business.

iii. It is frequently utilised in the machining of aluminium and brass.

iv. It finds use in production environments of all sizes, from the very large to the very small.

v. It is used in the production of additive manufacturing materials.

Advantages of CNC Machine

These are some advantages of using CNC Machine.

a. The positional accuracy of the component that is manufactured is significantly improved thanks to the utilisation of Servo Motors as the driving units.

b. The programme can be entered into the system much more quickly and easily through the keyboard.

c. It will be simpler to duplicate software programmes; for example, the software programme can be duplicated onto floppies or discs, and it can be installed on an unlimited number of computers.

d. The lifetime of a programme is effectively infinite because of the software that runs it.

e. Modifications to the design can be readily implemented into the programme that is already in place.

f. It is possible to automate the CNC machine entirely because to the fact that there are relatively few manual controls.

This type of system is software-based, so it follows that the machine tools are also managed by computer programmes. Using this approach, traditional machining procedures are made much easier to implement. In spite of the fact that computer numerical control machines (CNCs) are ubiquitous at this point, the productivity of any given industry has likely decreased due to their introduction. It is to one's advantage to acquire competence in the field of CNC machinery given the direction in which Manufacturing Technology is moving.

FAQ: CNC machine

Q. What is a CNC cutting machine used for?

Ans. The CNC cutting machine are used for slice through a wide range of materials, including wood, composites, metals, plastics, glasses, and foams.

Q. Is CNC the same as lathe?

Ans. CNC is an abbreviation for "computerised numerical control, and The traditional lathe relies on the operator's manual control of all axis motions.

Q. What are CNC machined parts?

Ans. Control Panel, Machine Tools, Motors, Feedback Mechanism, Screen are the main parts of CNC machine.

Related Blog Topic:

Manufacturers & Suppliers of Cnc Machines

Company Name | Member Since |

|---|---|

Lakshmi Electro Controls & Automation Bengaluru, India | 19 Years |

A Innovative International Ltd. Ahmedabad, India | 17 Years |

Patson Machines Pvt. Ltd. Pune, India | 16 Years |

Solar Cnc Automation Vadodara, India | 13 Years |

Hunkjet Laser Pune, India | 12 Years |

Shanghai Qianshan Piping Technology Co., Ltd. Shanghai, China | 12 Years |

Didac International New Delhi, India | 11 Years |

Success Technologies Ahmedabad, India | 11 Years |

Taizhou Winstrong Special Net Co., Ltd. Taizhou, China | 11 Years |

Tirupati Cnc Products Rajkot, India | 6 Years |

Popular Products