Insulation Material

(4550 products)Metasteel Prefab Private Limited

Gandhinagar

Trusted Seller

Trusted Seller Super Premium

Super Premium Premium Seller

Premium Seller5 Years

Super Premium

Super PremiumAcoustic Insulation Jackets Application: Plants Operating At High Temperatures

Price Trend: 5000.00 - 6000.00 INR/Square Meter

MOQ100 Square Meter/Square Meters

Density100-1000 Kilogram per cubic meter (kg/m3)

Product TypeJackets

MaterialFiberglass

Width600 Millimeter (mm)

ApplicationPlants operating at high temperatures

ColorSilver

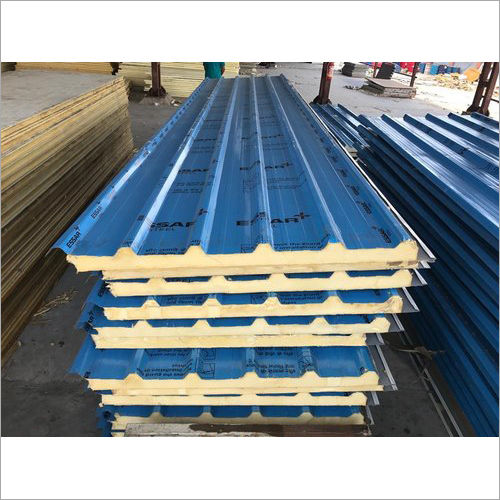

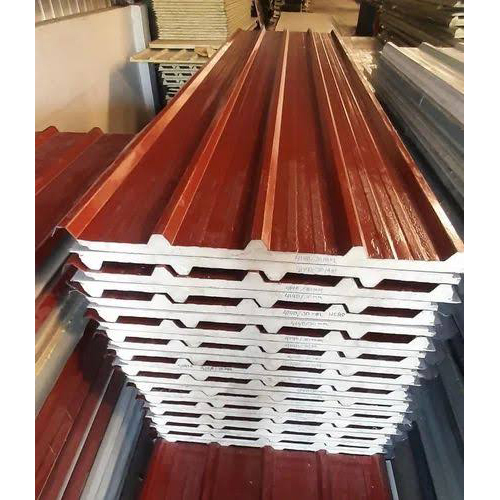

Puf Insulated Panel - Application: Industrial. Commercial & Residential

Price: 1450 INR/Square Meter

MOQ1000 Square Meter/Square Meters

Density40 Kg/Cu.mt to 80 Kg/Cu.mt Kilogram per cubic meter (kg/m3)

ApplicationIndustrial, Commercial

ColorBlue

Product TypePuff Insulated Panel

MaterialPUF

Main MaterialSteel

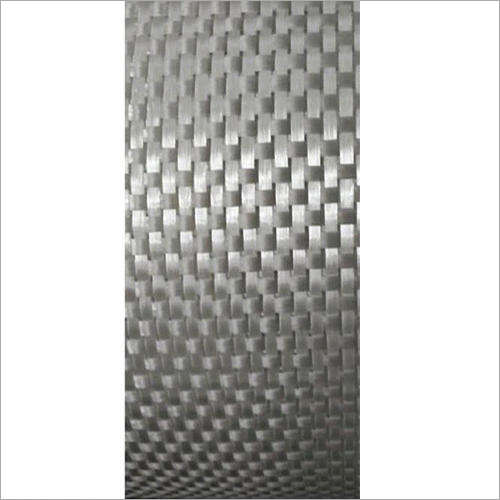

Fiberglass Cloth Application: Transformers

Price: 270 INR/Kilograms

MOQ100 Kilograms/Kilograms

Thickness0.15 / 0.20 / 0.25 / 0.30 Millimeter (mm)

ColorWhite

Length2 Meter (m)

Product TypeInsulation tape

MaterialFiberglass

Width1/2", 3/4", 1", 1.5" 2", 3", 4" Inch (in)

Harnawa Insulations Private Limited

Mumbai

Super Premium

Super Premium7 Years

Super Premium

Super PremiumEpoxy Insulator - Application: Industrial

Price: 16.00 INR/Piece

MOQ10000 Piece/Pieces

Product TypeEpoxy Insulator

MaterialFRP

ApplicationIndustrial

ColorRed

Zaral Electricals

Vadodara

Super Premium

Super Premium10 Years

Super Premium

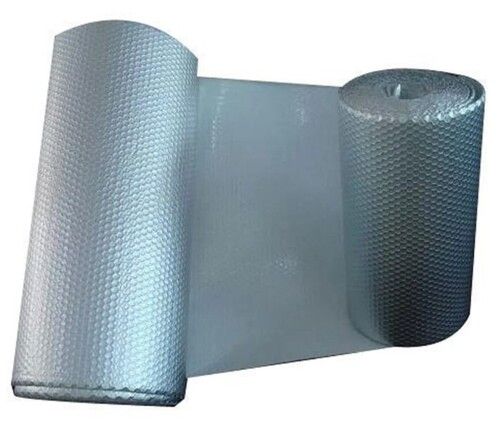

Super PremiumThermal Insulation Sheet - PPGI/PPGL Material, 0.45 Thickness , 0.503 Density for Industrial Applications

Price: 400 INR/Square Meter

MOQ100 Square Meter/Square Meters

Density0.503 Gram per cubic meter (g/m3)

Product TypeThermal Insulation Sheet

MaterialPPGI/PPGL

Thickness0.45 Millimeter (mm)

ApplicationIndustrial

Pushpak Infra Steel Private Ltd.

Pune

Flange Insulation Kit - Reinforced Phenolic & Nylon, API/ANSI/DIN Compliant Gasket Types E, F, D

Price: 2000 INR/Piece

MOQ5 Piece/Pieces

Product TypeINSULATING KIT

MaterialMetal

ApplicationIndustrial

ColorAll Color

Color Coated PUF Insulated Cement Sheet Wall Panel

Product DescriptionColor Coated PUF Insulated Cement Sheet Wall Panel

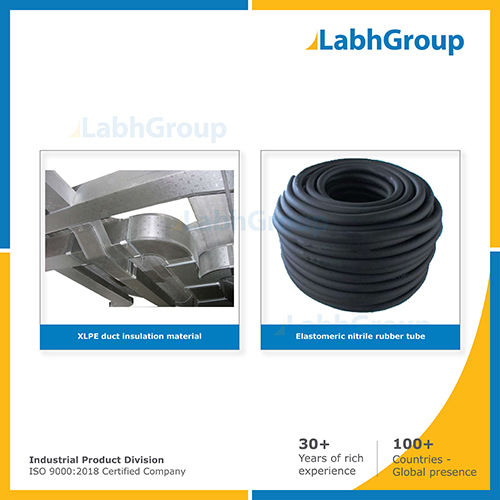

Supreme Hvac Insulation Material - Application: Industrial

MOQ10 , Piece/Pieces

Product TypeSupreme HVAC Insulation Material

Rated Voltage220 Volt (V)

ApplicationIndustrial

ColorGray

The Supreme Industries Ltd.

Mumbai

Super Seller

Super Seller8 Years

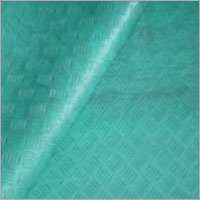

Sea Green Electrical Insulated Rubber Mats

Price: 300.00 INR/Piece

MOQ500 Piece/Pieces

ColorSea Green

Product TypeElectrical Insulated Rubber Mats

MaterialRubber

Thickness2.5 Millimeter (mm)

Softex Industrial Products Pvt. Ltd.

Kolkata

Super Seller

Super Seller18 Years

Insulation Rubber Mats - Application: Industrial

Price: 590 INR/Piece

MOQ1 , Piece/Pieces

ColorBlack

Product TypeInsulation Rubber Mats

MaterialInsulation Rubber

Thickness6-25 Millimeter (mm)

ApplicationIndustrial

Ameenji Rubber Limited

Secunderabad

Thermal Insulation Boards - Application: Industrial

MOQ1000 Piece/Pieces

Product TypeThermal Insulation Boards

MaterialXPS Board

Thickness25, 30, 50, 75 Millimeter (mm)

ApplicationIndustrial

ColorMulticolour

Aditya Packaging & Consulting Service Pvt. Ltd.

Pune

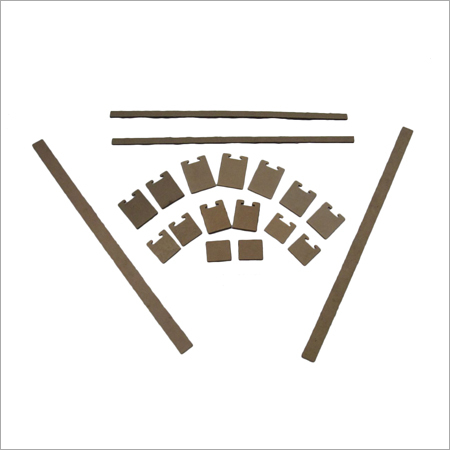

Press Board Strips - Cork Material, Insulating and Non-Corrosive Surface | Accurate Dimensions, Easy Installation, No Carbon Accumulation

MOQ100 Piece/Pieces

Product TypePress Board Strips

MaterialCork

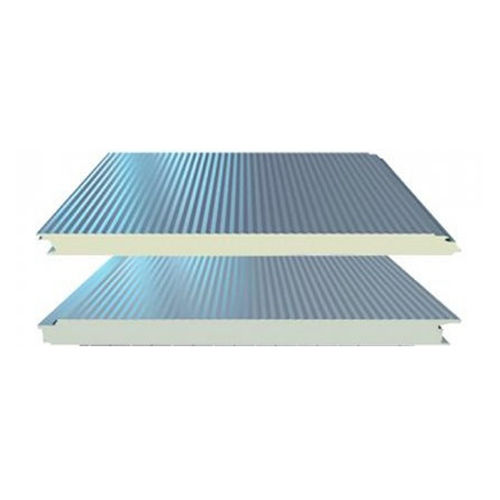

PUF Insulated Panels - Polyurethane Foam, 40 to 150 mm Thickness | High Thermal Resistance, Energy Efficient, Versatile Wall & Roof Application

Price Trend: 1500.00 - 5000.00 INR/Square Meter

MOQ50 Square Meter/Square Meters

Density40 Kilogram per cubic meter (kg/m3)

MaterialPolyurethane Foam

Thickness30 to 200

ApplicationWall & Roof

Krishna Insulations & Engineers Pvt Ltd

Vadodara

Super Seller

Super Seller15 Years

Hvac Insulation Material

Price: 800 INR/Piece

MOQ100 Piece/Pieces

Product DescriptionHvac Insulation Material

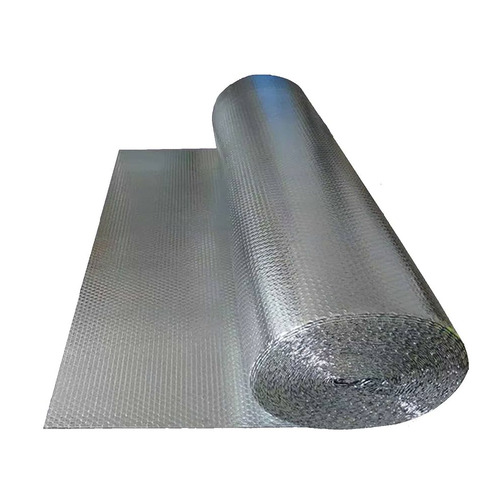

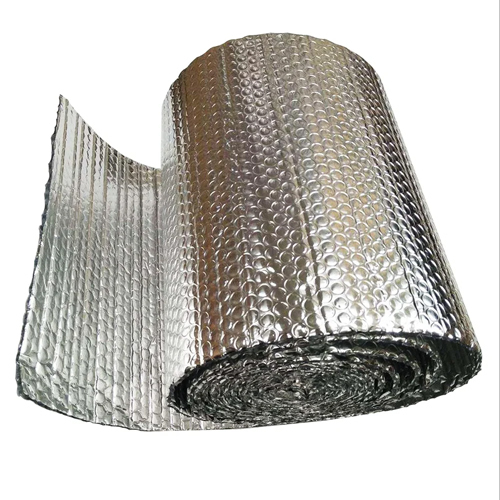

Reflective Insulation - Color: Silver

Price: 1000 INR/Square Meter

MOQ1 Square Meter/Square Meters

ColorSilver

Product TypeReflective Insulation

ApplicationInsulation

Woven Polyester Tape - Application: Industrial

Price Trend: 1.25 - 10.00 INR/Meter

MOQ20000 Meter

Width6 mm to 70 mm Millimeter (mm)

Thickness0.10 mm to 0.50 mm Millimeter (mm)

ApplicationIndustrial

Unitech Insulations & Cables (india) Pvt. Ltd.

Kolkata

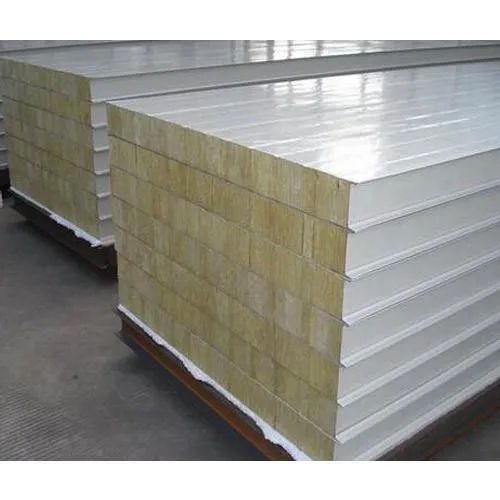

PUF Sandwich Panel - 60 mm Thickness, 1 Meter Width, White Color | Excellent Thermal Insulation, Durability, Fire Resistance

Price: 1600 INR/Square Meter

MOQ100 Square Meter/Square Meters

ColorWhite

Product TypePUF Sandwich Panel

MaterialPUF

Width1 Meter (m)

Thickness60 Millimeter (mm)

ApplicationIndustrial

Sfib-101 Braided

Price Trend: 900.00 - 920.00 INR/Kilograms

MOQ100 Kilograms/Kilograms

Supply AbilityAs per demand Per Week

Delivery Time2-3 Days

Dupont Nomex Paper - Color: White

Price: 4000 INR/Kilograms

MOQ1 Kilograms/Kilograms

ColorWhite

Product TypeDupont Nomex Paper

MaterialNomex Paper

Thickness.25 - 2 mm Millimeter (mm)

PUF Insulated Panels - 12m Length, 30-150mm Thickness | Efficient Cold Room Design for Beverages, Frozen Foods, Dairy Products, and Medicines

Price Trend: 1000.00 - 2500.00 INR/Square Meter

MOQone lot , Square Meter/Square Meters

MaterialOther

Nitrile Rubber Sheet

Price: 800 INR/Unit

MOQ100 Unit/Units

Product DescriptionNitrile Rubber Sheet

Insulated Windows - Application: Home And Hotel

Price: 400 INR/Square Foot

MOQ100 Square Foot/Square Foots

ColorWhite and Brown

Product TypeInsulated Windows

ApplicationHome And Hotel

Solid Core Insulator By Andisc Engineers Private Limited

Price Trend: 1500.00 - 11500.00 INR/Piece

MOQ10 Piece/Pieces

Payment TermsCash in Advance (CID)

Supply Ability1000 Per Week

Delivery Time5-7 Days

Andisc Engineers Private Limited

Kolkata

Hidden Screw Wall Panels - Application: Industrial

Price: 135 INR/Square Meter

MOQ100 Square Meter/Square Meters

Product TypeWall Panels

MaterialPUF

ThicknessDifferent Available Millimeter (mm)

ApplicationIndustrial

ColorOff White, Blue

Elements Technofab Private Limited

Pune

Slitted Insulating Kraft Paper Application: Industry

Price Trend: 500.00 - 2000.00 INR/Kilograms

MOQ1000 Kilograms/Kilograms

Product TypeInsulation Paper

MaterialWood Pulp

ApplicationIndustry

ColorGrey

Signature High Temperature Textile Cloth Temp.1200C - Application: Industrial

Price: 26250 INR/Roll

MOQ1 Roll/Rolls

ColorCream

Product TypeHigh Temperature Textiles

MaterialInsulation

ApplicationIndustrial

Latest From Insulation Material

Explore More Cities

Ready To Ship Insulation Material

Most Common Insulation Material In Industry

Introduction

Fiber materials including fiberglass, natural fibers, rock, slag wool, and cellulose are on the bulkier end of the insulation spectrum, while other options include stiff foam boards and sleek foils. In a building's hollow, bulky materials act as a barrier to both conductive and, to a lesser extent, convective heat flow.

Fiberglass is the most common insulation material in the Industry. Fiberglass, made of microscopic glass strands, is a popular insulator. Insulation blankets loose-fill, rigid boards, (both rolls and batts), and duct insulation all make use of this material.

These days, you may find fiberglass batt insulation in densities that are both somewhat denser and have better R-values than the old standard batts. Cathedral ceilings and other spaces with limited cavity space can benefit from the denser products.

Main Types of Insulator Materials

1. Insulation Facings

During production, insulation materials have their facings attached using fasteners. Facings are used to prevent damage to the insulation's surface, keep the insulation from shifting, and make it easier to attach the insulation to structural elements.

Some facings are also effective as air barriers, radiation barriers, and/or vapor barriers; others offer fire resistance.

If the seams between insulation boards are taped and sealed, then all of these materials will function as a vapor barrier and air barrier.

2. Phenolic Insulation Material

In the past, rigid foam board insulation made of phenolic foam was rather common. Available in board and foamed-in-place forms, its board insulation form is currently in short supply.

Air is used as the foaming agent in blown-in phenolic insulation. The fact that cured phenolic foam might shrink by as much as 2% is a major reason for its declining popularity.

3. Cementitious Insulation

Cementitious insulation is a spray-foam or foamed-in-place insulation made from cement-based foam. Aircrete® is a brand of cementitious spray insulation that has an initial viscosity like shaving cream because it contains magnesium silicate. When a space needs to be sealed, the professionals use air krete®.

Made from minerals (like magnesium oxide) derived from saltwater, cementitious foam is both inexpensive and safe to use.

4. Perlite Insulation Materials

Homes constructed prior to 1950 often have attics insulated with perlite. In order to create perlite, rock pellets are heated until they pop, resulting in very small, lightweight pellets. These results in a concrete that is lighter and less heat-conductive, or even a loose-fill insulating stuff composed of pellets that can poured into place.

5. Polyurethane Insulation Materials

Polyurethane is a low-conductivity gas-filled thermoset foam that is widely used as an insulator. Insulation made from polyurethane foam comes in both closed-cell and open-cell varieties.

High-density cells of closed-cell foam are sealed off and filled with a gas that allows the foam to expand and fill any empty spaces. Since the cells of open-cell foam are not as dense and are filled with air, the insulation has a softer, less dense feel and a lower R-value. It is possible for the R-value of closed-cell polyurethane Insulation Material to decrease with time, much like that of polyiso foam, due to thermal drift or ageing, which occurs when air replaces some of the low-conductivity gas that was previously there.

A material's R-value remains stable unless the foam is damaged, and thermal drift is greatest in the first two years following production.

6. Polyisocyanurate Insulation Materials

Low-conductivity gas is used to fill the closed-cell foam, which is manufactured of thermosetting plastic.

Polyisocyanurate insulation comes in a variety of forms, including liquid, sprayed foam, or rigid foam board. It's also useful for creating laminated insulation panels with customizable skins. Foamed-in-place uses of polyisocyanurate insulation can be more cost-effective than using foam boards due to the insulation's ability to conform to irregularly shaped areas.

7. Polystyrene Insulation Materials

Foam beads are another form of the insulating material molded expanded polystyrene (MEPS), which is more usually seen in foam board form. Although they are useful as pouring insulation for concrete blocks, these beads are famously difficult to regulate due to their small weight, susceptibility to static electricity, and the difficulty of removing the insulation once it has been poured.

8. Cellulose Insulation Material

Cotton, sheep's wool, straw, and hemp are just few of the natural fibers that are put to use in the insulation industry.

- Hemp: In the United States, the usage of hemp insulation is uncommon because of its lack of public awareness.

- Straw: Straw bale building, common on the Great Plains of the United States 150 years ago, is seeing a renaissance.

- Sheep’s Wool: When sheep's wool is treated with borate, it becomes pest-, fire-, and mold-resistant, making it ideal for use as insulation.

- Cotton: Similar to cellulose insulation, cotton insulation is constructed from 85% renewable materials and 15% polypropylene fibers sprayed with carbonate to put out fires and repel pests and mice.

Wall Insulation Materials

For External Wall Insulation:

1. Insulation Layer

The primary insulator, typically mineral wool or expanding polystyrene. In most cases, this is attached to the exterior of the house using self-tapping screws:

Polystyrene features:

- Soft, breathable fabric

- The material has a low heat conductivity and absorption of water.

- High resilience to chemicals and aging

Mineral Wool Features:

- Additive for water resistance is possible.

- Fabric that allows airflow

- Low heat transfer

- Exceptional toughness

2. Glass Fibre mesh

- Made to improve the insulation wall's stability, adaptability, and binding

- Added after the insulation boards but before the final coat of render

- Applied by being pressed into an adhesive mortar and then smoothed over

For Internal Wall Insulation:

1. Stud Wall

Mineral wool is stuffed into a connected metal or wooden studwork frame. Paint or wallpaper can be applied after the surface has been plastered.

2. Rigid Insulation Boards

Rigid insulating material, typically foamed plastic, is adhered directly to the back of plasterboard and then mounted on the interior wall. There are additional fasteners used to keep the boards in place, and the joints are sealed to prevent air leakage.

Cavity wall Insulation:

The three most prevalent types of cavity wall insulation materials are:

1. Blown mineral fibre

Compressed air is used to blow strands of fiberglass or mineral wool into the space. For cavity walls, this is the norm.

2. Polystyrene beads or granules

The granules will either naturally adhere to one another, or a sticky resin will be added to them (beads).

3. Urea formaldehyde foam

The cavity instantaneously filled after two chemical components were delivered at the same time.

Type And Use of Insulation Materials

There are several uses for insulating materials, including

- Transmission lines and cables

- Technology-based Methods

- Electrical grids

- Equipment for use around the house that may be carried with relative ease

- Electric cable insulation tape

- Gear for self-protection

- Rubber floor mats with built-in electric conductors

These days, cellulose, foam, and fiberglass are typically used as insulation. Now spray foam, loose-fill, Batts, and rigid foams are the most commonly used types of insulation. Even though these are the most frequently chosen options, the best choice will depend on your individual circumstances.

There isn't really a "best" insulation available. Each has advantages and disadvantages, and some are better suited to certain tasks than others. What kind of insulation is ideal for your home depends on a number of factors, including your climate, the areas of your home you intend to insulate, the amount of money you have available, and whether or not your home is already built.

FAQs: Insulation Material

Q. What are hot and cold insulation materials?

Ans: Hot Insulation material is made to reduce heat loss for energy efficiency and to shield workers from potentially dangerous temperatures. Reducing heat transfer to pipes, preventing condensation and ice buildup on outside surfaces, and ensuring worker safety are all made possible by cold insulation material.

Q. Best insulation materials suppliers in india?

Ans: Aerolam is one of the best insulation suppliers in India. To be more precise, Aerolam is a multifaceted organization that has manufacturing expertise in FIBC (PP Woven Jumbo Bags), Reflective Insulation Material, and CPP Film Especially for Medical & Food grade Packaging.

Q. What is the cost of insulation materials?

Ans: The price of insulation materials is between Rs 400-5500 square meter in India.

Q. How we can purchase insulation materials in bulk?

Ans: If you’re looking insulation material in bulk, Trade India would be the best place to get ideal deal. Look for the supplier who offers the reasonable and high quality insulation material at Trade India.

Manufacturers & Suppliers of Insulation Material

Company Name | Member Since |

|---|---|

Mag Hard Insulators Mumbai, India | 21 Years |

Everest Composites Pvt. Ltd. Vadodara, India | 18 Years |

Softex Industrial Products Pvt. Ltd. Kolkata, India | 18 Years |

Ganpati Engineering Industries Jaipur, India | 16 Years |

Ganapathy Industries Bengaluru, India | 16 Years |

Natraj Insulation Vadodara, India | 15 Years |

Krishna Insulations & Engineers Pvt Ltd Vadodara, India | 15 Years |

Shree Umiya Glass Works Anand, India | 15 Years |

Andisc Engineers Private Limited Kolkata, India | 15 Years |

Ameenji Rubber Limited Secunderabad, India | 13 Years |

Popular Products