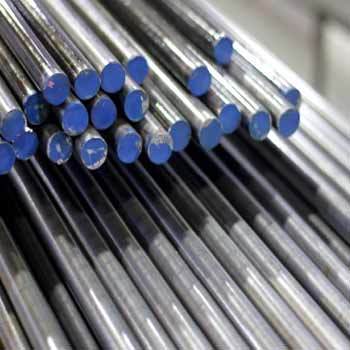

Bright Bars

(11116 products)Round Bright Bars - Color: Sliver

MOQ5 Ton/Tons

MaterialSS

ColorSliver

Product TypeBright Bars

UsageIndustrial

ShapeRound

TechnicsHot Rolled

Hot Die Steel Bars - Durable Alloy Steel, Versatile Mechanical Integrity and Dimensional Precision for Engineering Applications

Product DescriptionWe have many years experience and have good reputation, we are involved in exporting and trading Hot Die Steel Bars. Our Steel Bars fit for various construction and engineering purposes owing to their mechanical and dimensional properties. Our customers can avail these steel bars from us at most rea

Mfs05 Ms Flat Sections - Color: Gray

MOQ100 Kilograms/Kilograms

TypeMFS05 MS Flat Sections

ShapeSquare

ColorGray

TechnicsCold Rolled

UsageConstruction

Surface TreatmentPolishing

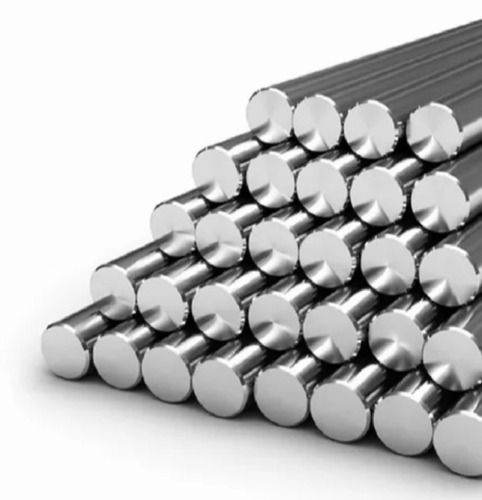

Steel Bright Bars - Color: Silver

Price: 85 INR/Kilograms

MOQ1 Kilograms/Kilograms

Surface TreatmentPolishing

TypeBar

MaterialSteel

ColorSilver

UsageConstruction

ShapeRound

Monel K 400 Round Bars - Aluminium, Small to Large Sizes, Silver Color | High Strength, Anti-Corrosive, Excellent Tensile Strength, Dimensional Accuracy

Price: 650.00 INR/Kilograms

MOQ500 Kilograms/Kilograms

Surface TreatmentPowder Coated

SizeSmall To Large

ColorSilver

Product TypeBars

Weight50-200 Kilograms (kg)

MaterialAluminium

Carbon Steel Round Bar - 3-4 inch Diameter, 36 Meter Length | High Strength, Corrosion Resistant, Hot Rolled Quality

Price: 65 INR/Kilograms

MOQ50 Kilograms/Kilograms

TechnicsHot Rolled

MaterialCarbon Steel

ShapeRound

ApplicationConstruction,Manufacturing

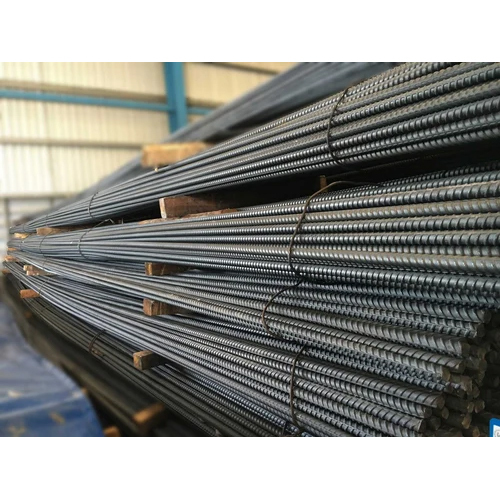

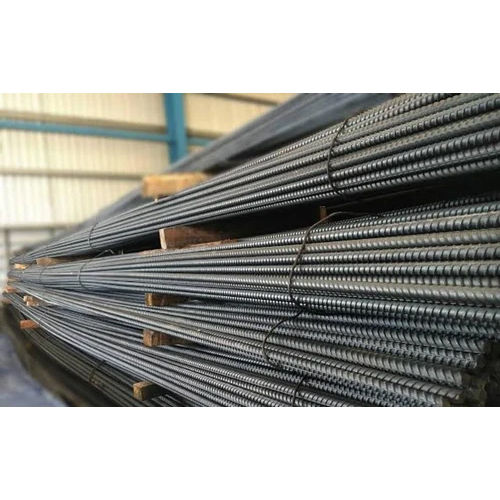

Tmt Bar By Apocalypse Steel and Power Limited

Price Trend: 440000.00 - 500000.00 INR/Ton

MOQ17 Ton/Tons

Supply Ability1000 Per Week

Delivery Time1 Week

Paper Best Price Tmt Bar

Payment TermsCash Against Delivery (CAD)

Main Domestic MarketAll India

Mild Steel TMT Bar - Cold Rolled, Black Finish | Industrial Grade for Comprehensive Usage in Industrial Applications

Price: 50000 INR/Metric Ton

MOQ10000 Metric Ton

ApplicationIndustrial, Construction

TechnicsCold Rolled

TypeTMT Bar

MaterialMild Steel

ColorBlack

UsageIndustrial

Ms Tmt Bar - Material: Stainless Steel

Price: 185 INR/Ton

MOQ25 Ton/Tons

UsageIndustrial

SizeDifferent Sizes Available

Surface TreatmentPolishing

MaterialStainless Steel

ShapeAny Shape

Hastelloy B2 Round Bar - Stainless Steel, Reliable Manufacturing & Supply Chain Efficiency

Payment TermsCash on Delivery (COD), Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Delivery Point (DP), Cash in Advance (CID), Cheque

Delivery Time3-4 Week

Sample AvailableYes

Aluminium Hex Bar 7075 - Application: Industrial

Price: 680 INR/Kilograms

MOQ50 Kilograms/Kilograms

ShapeAny Shape

ColorSilver

ApplicationIndustrial

UsageConstruction

TypeHex Bar

MaterialAluminium

Essto Engineering ( Unit - Ii )

Burdwan

Grey Corrosion Resistant Round Aluminum Bars

Price: 220 INR/Pack

MOQ50 Kilograms/Kilograms

LengthUp To 20 Foot (ft)

UsageIndustrial

ShapeRound

Grade6082 T6 / 6061 T6/ 7075 T651 / 2014 T651 / 2024 T351

TypeAluminum Bars

MaterialAluminum

Stainless Steel Bright Bars - Color: Silver

Price Trend: 10.00 - 100.00 INR/Piece

MOQ10 Piece/Pieces

GradeIndustrial

SizeStandard

ColorSilver

UsageIndustrial

TypeStainless Steel Bright Bars

MaterialSS

Mild Steel Tmt Bars - Grade: First Class

Price: 60 INR/Kilograms

MOQ2 Ton/Tons

TechnicsForged

UsageIndustrial

StandardNormal

MaterialStainless Steel

GradeFirst Class

Shubh M L Shah Sons Steel Private Limited

Navi Mumbai

Bright Bar - Optimal Quality Metal Alloys | Superior Strength, Excellent Formability, Durability, Corrosion Resistance

Product DescriptionAs a renowned entity, we are instrumental in distributing and supplying an excellent quality range of Bright Bar to the clients in Faridabad, Haryana, India. Known for manufacturing different kinds of components, the offered bar is extensively used in construction, automobile, ship building and othe

Standard Ms Bright Bars

Price: 95 INR/Kilograms

MOQ100 Kilograms/Kilograms

ShapeRound

TypeBRIGHT BAR

Applicationindustrial, automobile, construction, machinery, buildings, textile, etc

Thickness3MM TO 30MM Millimeter (mm)

Colorstandard

Product TypeMild Steel Bright bar

Sarvottam TMT Steel Bar

Price: 52300 INR/Ton

MOQ1 Ton/Tons

Supply Ability100 Per Day

Delivery Time6 Days

Main Domestic MarketAndhra Pradesh

Becu Round Bar - Application: Industrial

Price: 3300 INR/Kilograms

MOQ200 Kilograms/Kilograms

SizeStandard

ColorBrass

GradeA

ShapeRound

ApplicationIndustrial

MaterialBronze

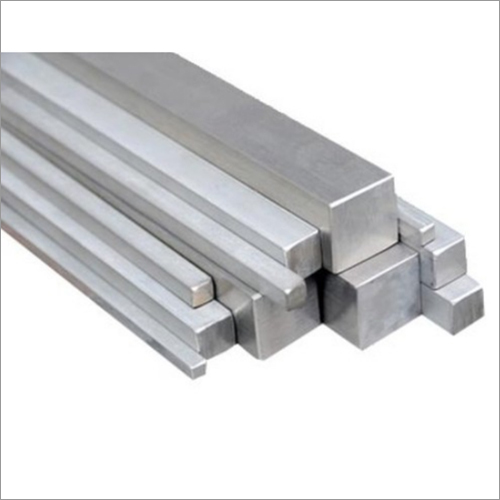

Mild Steel Square Bars - Application: Manufacturing

MOQ100 Kilograms/Kilograms

ApplicationManufacturing,Construction

Surface TreatmentPolishing

ShapeSquare

Product TypeMild Steel Square Bars

UsageConstruction

ColorSilver

En1a Hex Bar

Price Trend: 80.00 - 100.00 INR/Kilograms

MOQ10 Kilograms/Kilograms

Payment TermsCash in Advance (CID), Cheque, Cash Advance (CA)

Supply Ability1000 Per Day

Delivery Time2-3 Days

Righton Impex

Mumbai

Super Seller

Super Seller Premium Seller

Premium Seller11 Years

Galvanized Rods - Premium Quality Material, Long Service Life | Durable and Reliable Performance

Product Description\015\012Our company is considered as a leading company that manufacture, supply and trade a large range of Galvanized Rods. The offered Galvanized Rods are well known for their longer service life, to ensure the same, we manufacture these using supreme quality raw material, sourced from vendors of

Polished Finish Corrosion Resistant Mild Steel Square Shape Bar for Industrial

Price: 60 INR/Piece

MOQ1000 Piece/Pieces

MaterialMild Steel

GradeIndustrial

Surface TreatmentPolishing

TypeBar

Usagefor Industrial

Product TypeBar

Pratap Re Rollers Pvt. Ltd.

Panvel

Premium Seller

Premium Seller2 Years

Square Bright Bar - Alloy Steel, Hot Rolled Polished Finish | Versatile Application in Engineering and Automotive Industries

Price: 150 INR/Kilograms

MOQ1000 Kilograms/Kilograms

ApplicationConstruction Engineering Automobiles

TechnicsHot Rolled

TypeSteel Bright Bars

MaterialAlloy Steel

Surface TreatmentOther, Polished

ShapeSquare

Tmt Steel Bar - Application: Construction

Price: 60 INR/Kilograms

MOQ60 Metric Ton/Metric Tons

Thickness8 MM to 32 MM Millimeter (mm)

ApplicationConstruction

Steel TypeMild Steel

TypeTMT Bars

GradeIndustrial

MaterialSteel

Aluminium Bright Bar - Premium Quality Material | Versatile for Industries, Pharmaceuticals and Architecture

Price: 165 INR

Sample AvailableYes

Sample PolicyContact us for information regarding our sample policy

Main Domestic MarketAll India

Hot Rolled Mild Steel Square Bright Bar - 30 mm Diameter, 70HRC Hardness, 3 Meter Length, Metallic Grey Color, Durable for Construction

Price: 55 INR/Kilograms

MOQ100 Kilograms/Kilograms

Product TypeSquare Bright Bar

ColorMetallic Grey

ApplicationConstruction

Length3-6 Meter (m)

TypeBright Bar

MaterialMetal

Hastelloy C276 Bright Round Bars

Product DescriptionWe are widely recognized exporter, manufacturer and supplier of a populous range of Hastelloy C276 Bright Bars in Mumbai, Maharashtra, India. The offered Hastelloy C276 Bright Bars are broadly demanded for their qualitative features of finishing, strength and durability.\015\012

Latest From Bright Bars

Ready To Ship Bright Bars

What are Bright Bars?

The process of cold drawing stainless steel alloys in a cold reduction mill results in the production of bright bars, which are raw materials. Bright bars are used in a variety of applications. They have a molecular structure that is both geometrically perfect and exceedingly smooth, with a surface finish that is always extremely brilliant.

Because of this, the structure is referred to as a "Bright Bar." The majority of its make-up is stainless steel, but it also contains variable amounts of carbon and trace amounts of a variety of other elements, including chromium, manganese, iron, and others.

Bright bars are utilised extensively throughout practically all sectors of the economy as a result of the strength, durability, and, most significantly, corrosion-resistant qualities that they possess.

They have good weld ability and machinability, which makes them extremely advantageous for precision machining components and the construction of large, durable structures. Because of their outstanding weldability and machinability, they may be used in a variety of applications.

Different Types of Bright Bars

Here are the most common types of bright bars.

1. Bright Round Bars

A bright round bar with great hardness is the result of significant heat treatment during the bright bars manufacturing process. It is not difficult to improve its qualities by including other elements into the alloy.

2. Bright Hex Bars

The hexagonal shape of hex bars is primarily intended for use in the production of small threaded components and fasteners, such as nuts, valves, hose ends, fasteners, and hex bolts, among other things.

Because of their consistent strength and long-lasting nature, hex bars are frequently utilised in all manner of fastening applications.

3. Bright Rectangular Bars

Bright Rectangular Bars Due to their exceptional resistance to both heat and external impacts, bright rectangular bars are widely regarded as the material of choice for the production of machining components that are relatively small.

Before being prepared for machining, rectangular bright bars made of stainless steel go through the processes of heat treatment, cold drawing, annealing, and tempering.

4. Bright Flat Bars

These are ideally suited for engineering applications that require steel with increased strength and find employment in fields such as general engineering and fabrication work, as well as in the grating industry, component manufacture, and other related fields.

The diameter of a standard stainless steel rectangular bar can range anywhere from 12 to 50 millimetres.

5. Bright Square Bars

Bright Square Bars are offered in sizes ranging from 4mm to 80mm, and there are three different manufacturing options to choose from rolling, concast billet, and VSP billet.

Due to the fact that these are made of medium-strength steel, they have exceptional tensile strength, which enables them to be utilised in production procedures that involve studs, keys, shafts, stressed pins, and other similar components.

6. Steel Bright Flat Bars

Steel Bright Flat Bars that are manufactured using raw materials of the highest possible quality to provide long-lasting performance in any given application. The bright steel flat bars can be purchased in a wide range of dimensions, and they are utilised in a wide variety of business sectors.

Where are Bright Bars Used?

Bright bars are an essential component in the production process in a variety of sectors, including the following.

1. The application of engineering and building techniques to rapidly provide massive structures with stability, strength, and durability.

2. In the field of automotive manufacturing for the purpose of designing frames and chassis.

3. For the purpose of designing railings, trellises, and fences in communities and public areas.

4. For the purpose of fabricating machine components in a variety of forms and dimensions.

5. For the manufacture of fastener products ranging in size from micro to mega, suitable for use in all kinds of industrial and non-industrial applications.

Here is a list of some important ways that the Bright bars are used in different fields.

1. Automobile industry

bars made of shiny metal that are going to be put to use in the construction of vehicle frames and chassis. Bright bar manufacturers don't have to go to a lot of trouble to produce these goods because the dimensions, accuracy, and stability are all extremely exact.

2. Production of machine components

brilliant bars are incorporated into the conception of new and enhanced forms of automobile accessories. Bright bars offer strength, durability, and corrosion resistance. These benefits are beneficial for a variety of engine components, including drive shafts and smaller engine parts.

The construction industry and the engineering industry make use of high-grade materials because of the superior resistivity and higher hardness that this material possesses.

They offer a high tensile strength in addition to a stable foundation, both of which contribute to the accelerated completion of projects utilising modular Bright Bars products.

Ferritic steels, which are used to create solenoid bars, are also put to use in the production of electrical and electromagnetic components, electronic fuel injectors, plungers, and a wide variety of other components.

3. For design and decors

Bright bars ensure that the bright bars they produce are of a high enough quality to be used in the production of fashionable and decorative artworks.

Bright bars are used in the production of a wide variety of home accessories thanks to their exquisite formability, dimensional resistance, and finishing.

4. In the Sports and Hospitality sector

Within the Sports and Hospitality Industry Within the Sports and Hospitality Industries, It has resulted in a revolution as well as a significant development in the quality of service provided in these industries.

In addition to being utilised widely in the production of utensils and appliances utilised in the food business, it is extensively utilised in the production of surgical tools and clinical tools in hospitals.

5. In Rails and Trellis

Bright Bars Manufacturers offers square, round, and flat bright bars for use in the manufacturing of trellis and fences under the trade name Rails and Trellis. Because of its sturdiness and ability to tolerate friction, heat, and variations in the environment, the backbone of railway rails is utilised.

6. Manufacturing of tools

The production of tools and other implements relies heavily on the usage of Bright Bars. It is possible to economically mill the tools into a variety of sizes and dimensions thanks to the material that is used in the Bright Bars.

7. In the making of mechanical fasteners

Hardened steel bright bars are used extensively in the production of a diverse range of fasteners, including but not limited to basic nuts and bolts, anchors, rivets, and many others. Manufacturers of Bright Bars create these products in bespoke dimensions to fulfil customers' specific requests.

8. Other Applications

Numerous agro-based businesses employ bright bars as a tool to improve the efficiency of their farming procedures. High-grade stainless steel can also be found in applications such as military hardware, guns, and other such things.

They are also put to use in the high-stress tasks that are common in the mining and petroleum industries.

Because bright bars are used in such a diverse range of applications, they must all be manufactured and tested in accordance with international standards to guarantee their safety and high level of performance.

How are Bright Bars Manufactured?

Bright Bars made by cold drawing, centreless grinding, peeling, shaving, turning, or a combination of these techniques. It has improved mechanical qualities because to its increased precision in size, straightness, and surface finish. When it comes to Bright Bars, Metals can provide them in the following steps.

1. Raw material

The raw/input material consists of steel bar that has been heat rolled. Because of the high temperatures, the products that are hot rolled tend to have a surface that is rough and scaled. They may also have differences in diameter and length as a result of the extrusion process.

2. Drawing

During this stage of the process, the material is allowed to reach room temperature. One end of each bar is then inserted into the gripping device of the drawing machine.

The bar is drawn or pulled through the die by the mechanism that does the drawing. The diameter of the original bar is made thinner by the die, while the length of the bars is made longer.

3. Finished product

The completed item is called a drew bar, which can also be referred to as a cold drawn bar. This process results in a bright or polished surface.

This procedure enhances the mechanical qualities of the material, improves its machining characteristics, and produces diameter tolerances that are exact and uniform.

Peeling process

1. Raw material

The hot-rolled steel bar production process requires raw or input material. Because of the high temperatures, the products that are hot rolled tend to have a surface that is rough and scaled. They may also have differences in diameter and length as a result of the extrusion process.

2. Peeling

During this step of the process, the material is peeled while it is at room temperature. The peeling machine receives the bars from the feeder rollers via the feeding system. The tolerances of the peeled bar are even better than those of the drew bar.

3. Finished product

The peeled bar produces a bright or "spirally" polished finish with improved machining characteristics, increased mechanical qualities, and precise and consistent diameter tolerances. Additionally, the peeled bar has increased mechanical properties.

4. Grades

Steel can be produced in a variety of grades, including EN3A, EN8, EN9, EN19A/R, and EN19T. These grades are referred to as "grades." Various applications make use of each grade in its various forms.

5. Sizes

The size range is rather extensive, going from 16 to 160 millimetres in the peeled form and from 6 to 80 millimetres in the drawn form. The diameter range varies depending on the different types of materials.

The bright bar has very precise tolerances and helps save time during the manufacturing process. Rollers, pins, axles, and precision components are just some of the applications of this material.

FAQ: Bright Bars

Q. Key features of bright bars?

Ans. The most important distinguishing property of brilliant bars is that they are both geometrically in the correct shape and have dimensional tolerance that is extremely tight.

Q. How to select the right bright bar?

Ans. To select the right bright bar, here are some guidelines:

1. Consider the budget

2. Consider the price of the bright bars

3. Size of the bright bars

4. Manufacturing Quality

5. Material

6. Brand

Q. Can you weld a bright bar?

Ans. Yes, bright bars can be moulded and welded easily.

Q. What grade of steel is the bright bar?

Ans. Steel Grade: EN8, EN 19/R EN3A, EN9 and EN19T. These grades are mostly used with their own styles.

Q. Which material is used for bright bars?

Ans. Most of the material is stainless steel, while small amounts of carbon and metals like manganese, iron, chromium, etc. may be present.

Q. What are the sizes of bright bars?

Ans. Sizes are 10mm to 75mm in bring bars and 16mm to 150 mm in black bars.

Q. What grade is the bright bar?

Ans. The Grade of the bright bar is SAE 1008/7887/1010/1018/IS 2062.

Q. What is the difference between bright bars and black bars?

Ans. When raw materials like billets, blooms, etc. are heated to temperatures above 1200 C (about 2100 F), they are run through a series of rolls to make black bars. Steel may be shaped into any form and scaled to any size within this temperature range. On the other side, a bright bar, in the simplest terms, is an enhanced, computer-generated version of a black bar. In cold-reduction mills, bright bars are produced via the drawing process before undergoing additional processes including grinding, annealing, polishing, turning, and temper rolling while still at room temperature.

Related Blog Topic:

Best Listed Bright Bars Manufacturers, Suppliers & Exporters in India - Top 10

Manufacturers & Suppliers of Bright Bars

Company Name | Member Since |

|---|---|

Steel Mart Mumbai, India | 19 Years |

Precise Alloys Pvt. Ltd. Mumbai, India | 18 Years |

Govind Metal Co. Ahmedabad, India | 17 Years |

Jindal Rolling Mills Ltd. Hisar, India | 15 Years |

Vishal Steel Industries Mumbai, India | 15 Years |

Maxal Impex Mumbai, India | 11 Years |

Righton Impex Mumbai, India | 11 Years |

Jai Jirawal Metal & Alloys Mumbai, India | 10 Years |

Apocalypse Steel And Power Limited Howrah, India | 9 Years |

Essto Engineering ( Unit - Ii ) Burdwan, India | 8 Years |

Popular Products