Dies & Moulds

(6679 products)Polycarbonate Moulded Products - Color: Transparent

Price: 500 INR/Number

MOQ100 Number

UsageIndustrial

SizeStandard

ColorTransparent

TypeSynthetic Rubbers

Shaping ModeBlowing Mould

GradeIndustrial Grade

Polyerubb Industries

Ahmedabad

Super Bonanza

Super Bonanza16 Years

Plastic Hdpe Molded Bend 90 Degree

Price: 100.00 INR/Piece

MOQ120 Piece/Pieces

ColorBlack

Weight100 Kilograms (kg)

UsageFor pipe fitting

Product TypeHDPE Molded Bend 90 Degree

MaterialPlastic

Sangir Plastics Pvt. Ltd.

Valsad

10 Years

Quick Release Nipple - Color: Silver And Golden

Price: 365.00 INR/Piece

MOQ10 Piece/Pieces

Product TypeNipple

ColorSilver and Golden

UsageFire Fighting Equipment

MaterialSteel

Shaping ModeBlowing Mould

Warranty1 Year

Brilliant Engineering Works

Mumbai

21 Years

Multicolour Tablet Die Punch Polishing Kit

Price: 25000 INR/Unit

MOQ1 Unit/Units

Product TypeTablet Die Punch Polishing Kit

UsageIndustrial

ColorMulticolour

MaterialMetal

Innovative Engineering Works

Ahmedabad

Super Bonanza

Super Bonanza4 Years

Super Premium

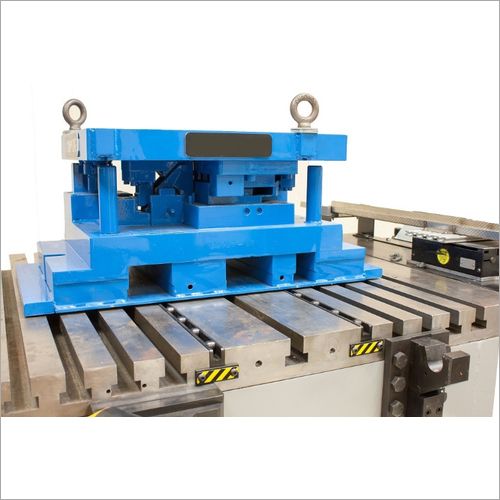

Super PremiumSheet Metal Stamping Dies - High-Quality Material, Custom Specifications | Precision Engineering and Durable Design

Product DescriptionOur organization is well recognized and identified as a major manufacturer and supplier a substantial selection of Sheet Metal Die in Indore, Madhya Pradesh, India. Offered Sheet Metal Die is designed and manufactured using optimum grade material and emerging techniques under the visionary supervisi

Mnt Industries

Indore

10 Years

Printed Pvc Moulding And Flower - Color: Golden

MOQ10 Piece/Pieces

Product TypePrinted PVC Moulding And Flower

UsageIndustrial

ColorGolden

SizeStandard

MaterialOther, PVC

Shaping ModePlastic Mould

J R Enterprises

Bhiwandi

3 Years

Kbr Hydraulic Laboratory Presses - Color: Blue

Price: 37950 INR/Unit

MOQ2 Unit/Units

UsageIndustrial

ColorBlue

SizeDifferent Size

MaterialMetal

WarrantyYes

Athena Technology

Thane

11 Years

Puri Cutting Dies

Price: 10500 INR/Piece

MOQ1 Piece/Pieces,

Supply Ability10 Per Day

Delivery Time15 Days

Jackson Machine

Ahmedabad

7 Years

Super Premium

Super PremiumDumbbell Cutting Die - Color: Silver

Price: 12000 INR/Piece

MOQ1 Piece/Pieces

UsageIndustrial

Product TypeDumbbell Cutting Die

ColorSilver

Power440 Volt (v)

Warranty1 Year

MaterialMild steel

Tej Engineers

Ahmedabad

5 Years

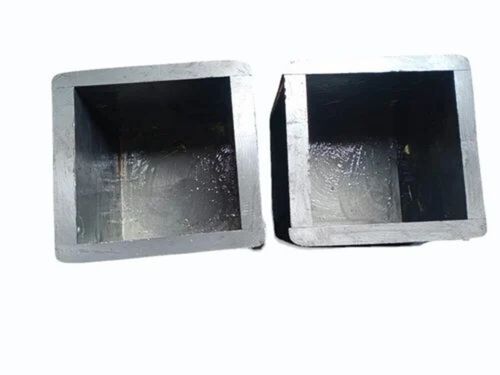

Beam Mould Capacity: 2000 Kg/Hr

Price Trend: 25000- 135000 INR/Piece

MOQ1 , Piece/Pieces

Usagecube testing

Capacity2000 Kg/hr

Machine Weight150 Kilograms (kg)

Yesha Lab Equipments

Ahmedabad

7 Years

Latches For Three Plate Mould Type C Application: Industrial

Price: 2000 INR/Unit

MOQ15 Unit/Units

ColorSilver

UsageIndustries

Warranty1 year

Length500 aEUR" 1000 mm Millimeter (mm)

SizeSurface Finish: 0.2 micron -.04 micron

Product TypeLatches

Vardhaman Dies And Moulds Tools

Mira Bhayandar

14 Years

Vertical Doulble Brick Mould Application: For Industrial Use

Price: /Unit

MOQ1 Unit/Units

FeatureLight Weight

ApplicationFor Industrial Use

Surface TreatmentGalvanized

TypeVertical Doulble Brick Mould

MaterialPlastic

ColorCream And Brown

Pam Industrial Plastics

Navsari

9 Years

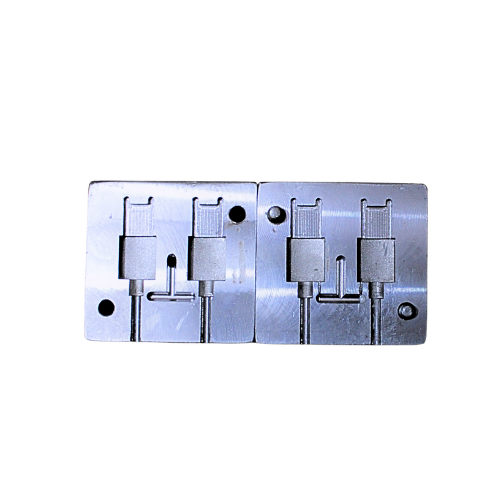

Paper Cup Mould Set, Type of CNC Machine: Mould

Product DescriptionPaper Cup Mould Set

Khalsa Engineering Works

Delhi

12 Years

Pvc Pipe Die Head - Color: Silver

Price: 100000 INR/Unit

MOQ1 Unit/Units

SizeCustomized

UsageIndustrial

ColorSilver

Product TypePVC Pipe Die Head

MaterialSteel

Shaping ModeDie Casting

Vital Force Engineering

Ahmedabad

7 Years

Super Premium

Super PremiumH C & Company

Pune

11 Years

Cube Moulds - Heavy Graded C.I. Casting , Available in 5cm, 7.5cm, 10cm, 15cm Sizes

Price: 750 INR/Pack

MOQ50 Pack/Packs

Product DescriptionWe manufacture cube moulds of 5 cm, 7.5 cm, 10 cm and 15 cm size. Our moulds are made of heavy graded C.I. casting.These are made by high grade of material. For further details, please visit our catalog

Balaji Construction Machinery

Rajkot

14 Years

Cast Iron Concrete Cube Mould - 150mm Size | Rugged Design, Lightweight, Smooth Finish, Longer Functional Life, Easy Maintenance

Price: 650 INR/Unit

Size150mm

MaterialOther, Cast Iron

Royal Hardware Mart

Kolkata

8 Years

Ve To Clamping Systems Private Limited

Faridabad

7 Years

Industrial Die Mounting

Price: 70000 INR/Piece

MOQ1 Piece/Pieces,

Product TypeDie Mounting

UsageIndustrial

MaterialStainless Steel, Other

J. B. Industries

Jaipur

14 Years

Cube Mould Box

Product DescriptionCube Mould Box:\015\012\015\012We are the leading manufactures and supplies a variety of scaffolding and fitting products. Among the offered products variety, our cube mold having base plate gained appreciation from our clients. It is manufactured and supplied in compliance to industrial standards

Guru Kirpa Scaff Private Limited

New Delhi

11 Years

Door Frames Rubber Mold - High-Quality Rubber, 7 Feet Tall, Sleek Black Finish | Precision Die Casting, Durable Threading Design

Price: 900 INR/Piece

MOQ50 Piece/Pieces

Working ProcessThreading

Height7 Foot (ft)

UsageConstruction

ColorBlack

MaterialRubber

Shaping ModeDie Casting

Saboo Plastics Pvt. Ltd.

Nagpur

1 Years

Pvc I Shaped Mould - Color: Yellow

Price Trend: 100.00 - 300.00 INR/Piece

MOQ100 Piece/Pieces

SizeStandard

Product TypePVC I Shaped Mould

ColorYellow

UsageIndustrial

MaterialOther, PVC

Royal Tile Machines

New Delhi

15 Years

Silver Vertical Molds

Price: 10000 INR/Piece

MOQ1 Piece/Pieces

ColorSilver

Product TypeVertical Molds

UsageIndustrial

MaterialSteel

Drishti Polymers

Ahmedabad

18 Years

Raameshth Electro Plasta Private Limited

Surat

11 Years

Aluminum Gravity Die Casting Dies

Price: 500000 INR/Set

MOQ1 Set/Sets

Product DescriptionAluminum Gravity Die Casting Dies

Castx Dies And Tools

Pune

3 Years

Regular Sev Sancha

Payment TermsOthers, Cash Against Delivery (CAD), Cheque

Sample AvailableYes

Sample PolicyContact us for information regarding our sample policy

Steel Sas Condor Stamper

Price: /Set

MOQ1 Set/Sets

UsageIndustrial

MaterialSteel

Shaping ModeDie Casting

Mahalaxmi Engineering Work

Mumbai

14 Years

Aluminium Extrusion Dies - Premium Quality Raw Material, Innovative Technology | Superior Durability, Customer-Centric Design

Product DescriptionBeing a customer centric organization, we are involved in manufacturing and supplying a supreme quality range of Aluminium Extrusion Dies in Silvassa, Dadra and Nagar Haveli, India. These dies are manufactured by utilizing supreme quality raw materials and innovative technology. Furthermore, we prov

Darshan Extrusions Pvt. Ltd.

Silvassa

1 Years

Latest From Dies & Moulds

Industrial Dies Moulds

By:

Rapid Techno Services

Mould Spare Parts

By:

Gaurabh Technology

PVC Plumbing Fitting Mould

By:

Shree Mahavir Enterprises

Industrial Dies

By:

Harindra Industrial Corporation

Dies Moulds Fixtures

By:

Ohm Sakthi Tooling

Ready To Ship Dies & Moulds

Dies and Moulds: Types & Applications

Compression molds, injection molds, transfer molds, and blow molds are all examples of basic mold types used in plastic processing, and they are typically categorized according to the number of cavities they include.

Dies And Moulds Meaning

Tools for making precise shapes include dies and molds. Sheet metal and other metal shapes can be shaped with dies. The automotive industry is a prime example of this type of use. In contrast, injection molding employs molds for the creation of plastic parts from liquid resin or metal castings from molten metal

In modern manufacturing, molds and dies are indispensable instruments for mass production. Molds are used in injection molding to form resin and in casting, while dies are used in stamping; both play critical roles in the production process. Modern methods allow for the creation of molds and die with micron-order precision, facilitating the mass manufacture of products with consistent form and quality across many industries.

Mould And Die Design

1. Stacked mold Design

The cavities in a stacked injection Dies & Moulds are arranged in rows and columns. This allows several cavities to be set up in a single device. By stacking four single cavities in an injection machine, for instance, four identical parts can be manufactured in a single cycle. As a result, the efficiency of the machine is increased. Injection molds are further classified as either Hot runner molds or Cold runner molds based on the feeding system.

2. Hot Runner mold Design

It is common practice for a hot runner mold system to include hot nozzles, temperature control boxes, manifolds, and accessories. An integral part of hot runner molds is the runner system, which is heated in advance by means of rods, coils, or heating components. In a three-plate mold, the runner system is contained within a stationary plate.

Even if the part cools down, the runner system will keep it at a safe temperature. A runner's mold is one in which the runner does not release the portion. There won't be a need to go through an extra step to get rid of the runner.

Due to the necessity for a heating system to heat the runner, hot runner molds tend to be more costly. It also increases the price of the mold by adding an extra plate. It's also difficult to clean the runner system because the runners are hard to access due to being embedded in the mold. Hot runner molds are more difficult to run and keep in good condition than cold runner molds. Changing the material of the part requires extensive labor on the part of the mold.

3. Transfer Die Design

Several tools can be operated with just one press using the transfer die. Using transfer dies has certain benefits, especially in mass production. To finish shaping a metal workpiece, it can freely transfer the work by adding shape.

In the past, each step of these procedures was completed by hand, with the workpiece being transferred manually between separate presses and dies. Single-press efficiency is greatly improved by automating the transfer process.

4. Progressive Die Design

A progressive die can do numerous operations at once, but it does so in stages at different machines. The progressive die is superior because of the increased productivity that comes from working quickly while using less force. The progressive die makes it simpler to achieve peak punching efficiency in a multi-station layout, despite the fact that its management is more complex than that of a single-station device. To mass produce complex components like those used in automobiles and electronics, engineers employ progressive dies.

Die Types:

1. Simple Die

One operation of every press slide stroke characterizes a simple die, also called a single-operation die. This die style is more commonly employed for less substantial tasks in the business world. Producing lightweight metal components is one such application.

2. Compound Die

With a compound die, you can accomplish more than one thing at once, such as cutting or punching. For more complicated blanking and piercing tasks, a compound die can complete the work more quickly. Instead of performing each step individually, the compound die may blank and pierce in one fell swoop. For mass-produced items, this is the best option.

3. Combination Die

The combination die is functionally and aesthetically identical to the compound die. Its multitasking abilities mean it can process multiple requests simultaneously, so you get more accurate and timely responses. The combination die has additional utility as a cutting and shaping tool.

Mold Types:

1. Single Cavity Mold

One of the most fundamental mold concepts is this mold. Only one part at a time can be molded using this mold.

2. Dedicated Multiple Cavity Mold

In order to mass-produce an item, factories will use specialized molds with several cavities. Because it is simple to regulate the plastic flow using this mold, it has found widespread use.

3. Family Mold

Due to the short molding times, prototype molds benefit greatly from family cavity molds. Multiple cavities in a family injection mold allow for the simultaneous creation of several identical products within a single molding run.

4. Two-Plate Mold

When creating plastic components, a two-plate mold is employed. This sort of molding is extremely frequent because of how simple it is to execute.

5. Three-Plate Mold

In three-plate molds, the runner is housed in the third plate, known as the striper. A double-action ejector mechanism ensures that the runner is not thrown out along with the component.

Difference Between Mould And Die

Die

A die is a specialized piece of machinery utilized in the industrial sector for cutting and/or forming materials into the desired form. A die is used to shape only two of a part's three dimensions, as opposed to a mold, which shapes the item from start to finish. Other process variables determine the third dimension, which is typically thickness or length. Tool steel, a special type of carbon steel and alloy steel is commonly used in the production of dies and other types of tooling such as cutting tools and hand tools. High strength, wear resistance, plus impact toughness at both room temperature and higher temperatures are the hallmarks of tool steels' unique alloy composition. Dies are helpful because of the volume of material they can cut.

Mold

A mold is a tool used in manufacturing that is designed to create objects of a specific design and dimensions. Materials can be shaped into components or finished goods by applying pressure using specialized tools that are mounted on the press as part of the manufacturing process. A mold is used to create a complete three-dimensional plastic item during plastic manufacturing. Metal-plastic forming molds, mold injection molds, and Casting molds are just a few examples of the many categories of molds, but their common purpose is obvious. Blow molding, reaction injection molding, thermoforming, and Injection molding are all mold-based plastics processing techniques.

Die And Mold Industry

1. Overview

From 2020 to 2025, the Indian dies and molds market is forecast to expand by USD 1.47 billion, representing a compound annual growth rate (CAGR) of 9%.

2. Trends and Challenges

As far as we can tell, the expansion of the market before, during, and after the COVID-19 era was unaffected. Growth in the dies and molds market in India is being propelled by new possibilities in aluminum metal injection molding, but the market could be stymied by issues including a shortage of competent workers in the industrial sector. The researchers have analyzed past data to identify the leading market drivers and the consequences of the COVID-19 pandemic for India's dies and molds sector. In order to deduce objectives and fine-tune advertising campaigns to get an advantage over the competition, a comprehensive analysis of the drivers is required.

3. Key Players

a- Godrej & Boyce Manufacturing Co. Ltd.

b- Alfa Plast Mould, Classic Die Tools

c- Hindustan Die Castings

d- Sankalp Engineering & Services Pvt. Ltd.

e- Nagata Auto Parts Co. Ltd.

f- JPM Group

g- Dietech India Private Limited

FAQs: Die And Mould

Q. What are the top die and mould manufacturers in India?

Ans. Here are the top manufacturers:

a- Godrej & Boyce Manufacturing Co. Ltd.

b- Hindustan Die Castings

c- Sankalp Engineering & Services

d- Greatoo Intelligent Equipment Inc.

Q. How to start dies and mould in India?

Ans. Here are the steps:

a- Find a niche and focus

b- Plant Layout

c- Warehousing for injection molding

d- Required molding machine

e- Select the equipment

Q. What are the applications of dies and mould?

Ans. Die cutters and molds serve the same function in the manufacturing industry. Metal sheets and other shapes can be formed using dies. Fabricating car bodies is a common use case. Conversely, injection molding, which can be done with molten resin or metal, requires the usage of molds.

Manufacturers & Suppliers of Dies & Moulds

Company Name | Member Since |

|---|---|

Brilliant Engineering Works Mumbai, India | 21 Years |

Drishti Polymers Ahmedabad, India | 18 Years |

Polyerubb Industries Ahmedabad, India | 16 Years |

Royal Tile Machines New Delhi, India | 15 Years |

Vardhaman Dies And Moulds Tools Mira Bhayandar, India | 14 Years |

Balaji Construction Machinery Rajkot, India | 14 Years |

J. B. Industries Jaipur, India | 14 Years |

Mahalaxmi Engineering Work Mumbai, India | 14 Years |

Khalsa Engineering Works Delhi, India | 12 Years |

Athena Technology Thane, India | 11 Years |

Popular Products