Heat Exchangers

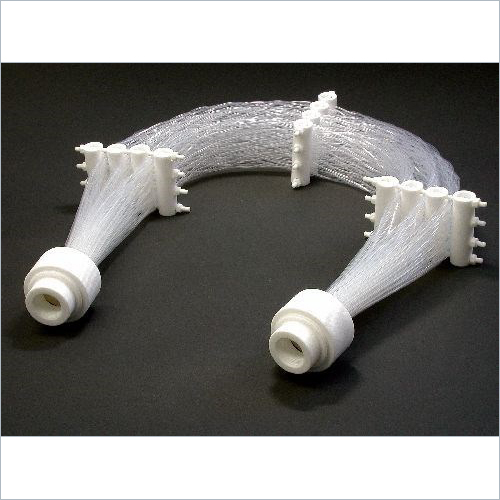

(5157 products)White Fluoropolymer Heat Exchanger

MOQ10 Unit/Units

ColorWhite

Product TypeFluoropolymer Heat Exchanger

Usageindustrial

ConditionNew

Structuretube Heat Exchanger

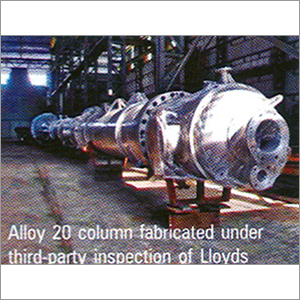

Industrial Heat Exchanger - Stainless Steel, Automatic Operation at Up to 280 Volt | High Durability, Effective in Cooling and Heating Processes

Price: 200000 INR/Unit

MOQ1 Unit/Units

Product TypeHeat Exchangers

UsageIndustrial

ConditionNew

Structuretube Heat Exchanger

Heat Exchangers - High-Performance Aluminum Alloy , Compact Design for Efficient Thermal Transfer

Price: 200000.00 INR/Unit

MOQ1 Unit/Units

Supply Ability10 Per Week

Delivery Time4-5 Months

Packaging DetailsPacking in corrugated box, shrink wrapping and wooden crates available.

Heatless Air Dryer - Color: White

Price: 5000 INR/Unit

MOQ1 Unit/Units

TemperatureHigh-temperature

Max. Capacity10 Cubic Feet Per Minute (ft3/min)

ColorWhite

UsageIndustrial

ConditionNew

Structuretube Heat Exchanger

Shell And Tube Heat Exchanger - Usage: Industrial

MOQ1 Unit/Units

TemperatureHigh-temperature

UsageIndustrial

ConditionNew

Structuretube Heat Exchanger

Voltage280 Volt (v)

Luftsol Engineering Private Limited

Pune

Gray Scraped Surface Heat Exchanger

MOQ1 Unit/Units

ColorGray

UsageIndustrial

Product TypeScraped Surface Heat Exchanger

ConditionNew

Structuretube Heat Exchanger

Voltage220 Volt (v)

Silver Thermic Fluid Heat Exchanger For Sago Industries

Price: 60000 INR/Piece

MOQ1 Piece/Pieces

UsageIndustrial

SizeDifferent Sizes Available

Colorsilver

Structuretube Heat Exchanger

Heat Exchanger - Color: Any

Price: 100000 INR/Unit

MOQ1 Unit/Units

ColorAny

UsageIndustrial

Product TypeHeat Exchanger

ConditionNew

Sunrise Process Equipments Private Limited

Mumbai

Grey Plate Pack Distribution Unit (Heat Exchanger)

Price: 400000.00 INR/Unit

MOQ1 Unit/Units

Product TypePlate Pack Distribution Unit (Heat Exchanger)

UsageIndustrial Use

ColorGrey

ConditionNew

Weight20.00 Kilograms (kg)

Sliver Heat Exchanger

Price: 150000 INR/Unit

MOQ1 Unit/Units

ColorSliver

Product TypeHeat Exchanger

Usageindustrial

ConditionNew

StructureOther, Heat Exchanger

Pratham Engineering

Mira Bhayandar

Trusted Seller

Trusted Seller14 Years

Industrial Plate Heat Exchanger - Stainless Steel Clad with SMS/IDF/Din/Tri Clover Fittings | Hassle Free Operation, Low Maintenance, Long Operational Life

Price Trend: 100000.00 - 300000.00 INR/Unit

MOQ1 Unit/Units

Product TypePlate Heat Exchanger

UsageIndustrial

ConditionNew

Heat Exchanger - Heavy Duty Raw Material for High Durability , Ideal for Various Industries

Product DescriptionThese Heat Exchanger are made by using very heavy and high quality raw material which ensures high durability at its user end. These Heat Exchanger are widely finds its applications in various industries

Vertical Thermic Fluid Heater - Up to 300°C, 25,000 to 1,500,000 Kcal/Hr | Fully Automatic Operation, High Thermal Efficiency, Clean & Smokeless Combustion

Product DescriptionIn recent times, thermic fluid heaters have found wide applications for indirect process heating. Employing petroleum - based fluids as the heat transfer medium, these heaters provide constantly maintainable temperatures for the user equipments. The combustion system comprises of a fixed grate with

Wood Fired Thermic Fluid Heaters Usage: Industrial

Price: 2500000 INR/Unit

MOQ1 , Unit/Units

Product TypeWood Fired Thermic Fluid Heaters

UsageIndustrial

ConditionNew

Voltage380 Volt (v)

Surface Steam Condenser - Alloyed Material, Large Cylindrical Design, High Rigidity and Strength | New Condition, Safe Operation at Extreme Temperatures and Pressures

Price: 2500000 INR/Unit

MOQ1 Unit/Units

ThicknessDifferent Available Millimeter (mm)

Product TypeSurface Steam Condenser

SizeDifferent Available

UsageIndustrial

ConditionNew

Karunanand Hydro-pneumatic Controls Pvt. Ltd.

Ambernath

Spiral Wound Heat Exchanger - Medium-Temperature, Grey | New Industrial Usage

TemperatureMedium-Temperature

ColorGrey

UsageIndustrial

Product TypeSpiral Wound Heat Exchanger

ConditionNew

Heavy Duty Heat Exchanger - Size: Different Sizes Available

Price: 135000.0 INR/Unit

MOQ1 Unit/Units

SizeDifferent Sizes Available

UsageIndustrial

ConditionNew

Heat Exchanger

Price: 15000 INR/Piece

MOQ1 Piece/Pieces

Supply Ability25 Per Day

Delivery Time25 Days

Packaging DetailsTransport

Air Cooled Heat Exchanger - Color: Black

Price: 1000000.0 INR/Unit

MOQ1 Kilograms/Kilograms

UsageIndustrial

SizeStandard

TemperatureHigh-temperature

Product TypeAir Cooled Heat Exchanger

ColorBlack

ConditionNew

Akshar Precision Tubes Pvt. Ltd.

Vadodara

Fpc Heat Exchanger System - Color: Grey

Price: 60000.0 INR/Piece

MOQ5 Piece/Pieces

ColorGrey

TemperatureMedium-Temperature

UsageIndustrial And Commercial

Product TypeFpc Heat Exchanger System

TypeSolar

ConditionNew

Sunzone Solar System India Private Limited

Bengaluru

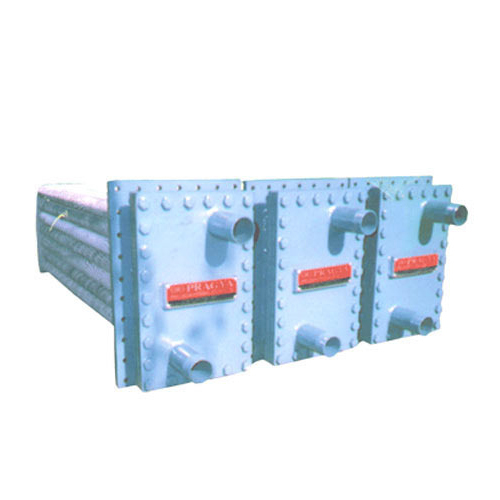

Grey Heat Exchangers

Price: 1000000 INR/Unit

MOQ1 Unit/Units

ColorGrey

UsageIndustrial

Product TypeHeat Exchangers

ConditionNew

Voltage220 Volt (v)

Power228 Watt (w)

Pragya Precision Equipment Private Limited

Indore

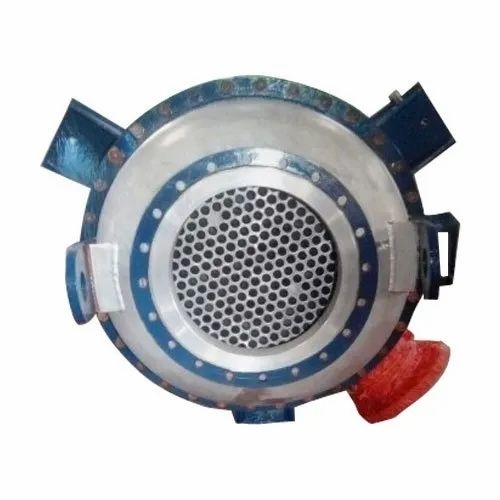

Shell and Tube Heat Exchanger

Price: 10000 INR/Unit

MOQ1 Unit/Units

FOB PortVadodara

Payment TermsCash Advance (CA), Cash in Advance (CID), Cheque, Others

Supply Ability100 Per Month

Prime Advance Polishing System Pvt. Ltd.

Vadodara

Shell And Tube Heat Exchanger - Customized Size for High-Temperature Use, Durable Design for Industrial Applications

Price: 45000 INR/Unit

MOQ5 Unit/Units

SizeCustomized

TemperatureHigh-temperature

UsageIndustrial

ConditionNew

Structuretube Heat Exchanger

Msm Process Solutions Pvt. Ltd.

Pune

Double Pipe Heat Exchanger - Copper Alloy, Compact Design, Efficient Heat Transfer, High Durability, Versatile Applications

Price Trend: 500000.00 - 1500000.00 INR/Set

MOQ1 , Set/Sets

Product DescriptionDouble Pipe Heat Exchanger

Industrial Heat Transfer Size: Customized

MOQ5 Unit/Units

UsageIndustrial

TemperatureHigh-temperature

SizeCustomized

ConditionNew

Structuretube Heat Exchanger

Heat Exchanger - Stainless Steel and Mild Steel, Ideal for Oil Field, Refineries, Pharma, Chemical, and Distillery Industries

Product DescriptionWe offer wide range industrial heat exchanger, which are made from stainless steel, mild steel and other suitable material. These heat exchangers provide solutions to industries like, oil field, refineries, pharma, bulk drug, petroleum, chemical, sugar, distillery industries

Utech Projects Pvt. Ltd.

Mumbai

Super Seller

Super Seller14 Years

Plate Heat Exchanger Phe - Color: Silver

Price: 250000 INR/Unit

MOQ10 Unit/Units

TemperatureHigh-temperature

SizeStandard

Product TypePlate Heat Exchanger Phe

ColorSilver

UsageIndustrial

ConditionNew

Ss Engineers And Consultants Private Limited

Rajahmundry

Shell and Tube Heat Exchanger - Copper, Steel, or Titanium Tubes | Blue Color, Different Sizes Available, 110-220 Volts

Price: 22500 INR/Piece

MOQ1 Piece/Pieces

SizeDifferent Size Available

UsageIndustrial

ColorBlue

Product TypeShell and Tube Condenser

ConditionNew

Voltage110-220 Volt (v)

Latest From Heat Exchangers

Heat Exchangers Chiller Tube

By:

Creative Cooling Technology

Shell And Tube Heat Exchangers

By:

Evershine Enterprises

Ready To Ship Heat Exchangers

What Is Heat Exchangers

Introduction

A heat exchanger, in its simplest form, is any device that moves heat from one medium to another; for instance, a Hydraulic Oil Cooler transfers the heat of heated oil to cool water or air. Pool water can also be heated via a heat exchanger that draws hot water from a boiler or solar heated water circuit. Through the materials of the heat exchanger, heat is exchanged between the two media. When cooling liquid, a shell and tube heat exchanger directs the fluid through and over the tubes, whereas an air cooled heat exchanger directs the air through a core of fins.

Types of Heat Exchangers

1. Micro channel heat Exchanger

They are multi-pass parallel-flow heat exchangers, and its components are input and exit manifolds, tubes with multiple ports, hydraulic channels thinner than 1 mm in diameter, and fins. When joining these components, a controlled environment brazing procedure is typically used.

2. Phase Change heat Exchanger

Due to the negligible size change between the solid and liquid states, this phase transition typically occurs. This phase transition acts as a buffer, allowing for additional heat to be acquired while maintaining a steady temperature. When it comes to energy storage, phase change materials really shine.

3. Adiabatic heat Exchanger

This particular heat exchanger finds widespread application in manufacturing. One side of the heat exchanger stores heat in a fluid while the other side transfers it elsewhere.

4. Finned heat exchanger

To better conduct heat in liquids with low thermal conductivity, like air, finned tube heat exchangers are built to refer to the highest heat transfer surface area with the exchanged heat. It's made up of a network of tubes with fins attached to maximize the surface area in contact with the external fluid and the surface area in contact with the fluid inside the tube, allowing for more efficient heat transfer.

5. Pillow Plate heat Exchanger

Products in manufacturing facilities can benefit from both their cooling and heating capabilities with these. As they inflate, the wavy "pillow-shaped" surface of these heat exchangers is formed. Typical applications for these include reboilers, water chillers, solids dryers, and so on. The cooling of milk in huge stainless steel bulk tanks is a popular application of this type of heat exchanger.

6. Plate Heat Exchanger

These heat exchangers use metal plates to transfer heat, as their name implies. The fluids in motion can move freely because of the channels formed by the metal plates.

Plate Heat Exchangers are constructed from many individual flat plates that are linked together to create a network of channels via which heat and cold can be transferred. This is because the heat penetrates the surface, creating a barrier between the hot and cold media.

For this reason, the energy required to heat or cool liquids and gases is quite small. Compared to shell and tube, they can sometimes be cheaper and take up less space. The water heating and air conditioning industries rely heavily on these.

7. Direct Heat Exchanger

In the absence of an insulating wall, direct heat exchangers facilitate the transfer of heat between two streams of hot and cold currents. The heat transfer process occurs concurrently when the hot and cold liquids are mixed together, eliminating the need for a heat exchanger. There are a few types of cooling towers and jet condensers.

8. Indirect Heat Exchanger

Because of the impermeability of the barrier between the two common fluids, the temperature difference between the two common fluids can be measured indirectly using an indirect heat exchanger. Tubes, plates, and other heat-insulating materials maintain the fluids being exchanged at different temperatures.

9. Double Pipe heat Exchanger

The inner pipe works as a conductive barrier, allowing one liquid to flow through it while another flows between it and the outer pipe. It finds widespread application in manufacturing, cooling technology, refrigeration, and other areas due to its high efficiency and low capital cost.

10. Tube in tube heat exchanger

The heating and cooling needs of sludge including fibers and particles are met by a tube-in-tube heat exchanger.

With the introduction of tube in tube heat exchangers, a tube is introduced inside of a tube. Within the tube, the product medium floats countercurrent to the service medium as the tube operates. The product tube may be plain or folded.

This innovative layout saves bulk, boosts performance, and stops thermal exhaustion.

11. Shell and Tube heat exchanger

These heat exchangers are the most popular and adaptable ones used today. Within a cylindrical housing, this heat exchanger's many tubes come into direct thermal contact with the two working fluids, exchanging heat in the process.

This configuration allows one fluid to move inside the tubes while another moves outside the shell. A shell and tube heat exchanger is a small, low-maintenance, and high-performing heat exchanger design. Preheating, oil cooling, and steam production are all possible with this heat exchanger.

What Is the Principle of Heat Exchanger.

Heat exchangers are predicated on the principles outlined in the laws of thermodynamics.

- 1. In a state of thermal equilibrium, all thermodynamic systems have the same temperature, as required by the Thermodynamics. If two systems are in thermodynamic equilibrium with a third, then the temperatures of all three must be equal.

- 2. It is impossible to create or destroy energy, according to the First Law of Thermodynamics, yet energy can be transferred from one medium to another in the form of heat.

- 3. A closed thermodynamic system has a natural, invariable tendency to rise in entropy over time, as described by the Second Law of Thermodynamics, which establishes entropy (S) as an extra attribute of thermodynamic systems.

What Are the Advantages of Heat Exchanger.

1. Minimal Operating Cost

Heat exchangers do not need to be maintained as frequently as air conditioners do since they do not employ complex external equipment and because they are designed to eliminate the majority of pollution.

They are also extremely durable, with the ability to outlive the majority of air conditioning units by many orders of magnitude before requiring maintenance, repair, or replacement.

2. Lower Environmental Impact

Heat exchangers have to be kept in a constant state of operation in order for them to be successful in preventing high-powered control panels from overheating.

The fact that modern heat exchangers do not need supplementary apparatus to function well, such as air conditioning or air compression units, is one of the most significant advantages offered by these devices.

As a result, in comparison to other, more conventional techniques of temperature control, they consume an enormous amount less energy and generate almost no pollution.

3. Smaller Spatial Footprint

It would appear that more powerful also means smaller as a result of the progression of modern technology.

This includes smaller personal devices, smaller and more adaptable manufacturing equipment, and a number of other examples. As the amount of space available in electrical cabinets decreases, the potential for heat pockets and the subsequent damage to electrical components increases.

As a result, there is an increased demand for cooling solutions that are both more compact and more effective, such as heat exchangers.

4. High Heat Transfer Coefficient

The heat transfer coefficient of the air-cooled heat exchanger is high, and it is commonly estimated to be three to five times higher than the heat transfer coefficient of the shell-and-tube heat exchanger.

The heat exchange area of an air-cooled heat exchanger is much less than half of the heat exchanges area of a shell-and-tube heat exchanger while performing the identical heat exchange duty;

5. Large Temperature Difference Correction Coefficient

The flow patterns of the two fluids in a shell-and-tube heat exchanger are typically described as being cross-flowing, as they take place in the shell and tube sections, respectively.

The logarithmic mean temperature difference needs to be adjusted since additional investigation reveals that the flow on the shell side is a mixed flow and the flow along the tube length is a multi-strand flow. In most cases, the factor is not very significant.

Air-cooled heat exchangers typically have either a countercurrent or concurrent fluid flow pattern.

FAQs: Heat Exchangers

Q. What are heat exchangers used for?

Ans: There are a wide variety of engineering uses for heat exchangers, including cooling, heating, air conditioning, power generation, waste heat recovery, vehicle radiators, and chemical and food processing.

Q. What is heat exchanger and example?

Ans: Shell & Tube is the most common heat exchanger example that uses for parallel arrangements of tubes.

Q. What liquid is used in heat exchangers?

Ans: Heat transfer fluids include liquids like synthetic oil, molten salt, and water. Due to its large thermal capacity and low viscosity, water makes for an excellent heat transfer fluid.

Q. Which type of heat exchanger is mostly used?

Ans: Shell and Tube are the main heat exchanger that is mostly used in food industry.

Manufacturers & Suppliers of Heat Exchangers

Company Name | Member Since |

|---|---|

Dipesh Engineering Works Mumbai, India | 23 Years |

Sunrise Process Equipments Private Limited Mumbai, India | 22 Years |

Hi-Tech Applicator Ahmedabad, India | 17 Years |

Steelfab Industries Vasai, India | 16 Years |

Prime Advance Polishing System Pvt. Ltd. Vadodara, India | 16 Years |

V Tech Engineering Indore, India | 16 Years |

Unique Air Products Vadodara, India | 15 Years |

K-Pack Systems Private Limited Bengaluru, India | 15 Years |

Pratham Engineering Mira Bhayandar, India | 14 Years |

Utech Projects Pvt. Ltd. Mumbai, India | 14 Years |

Popular Products