Industrial Dryers

(2806 products)Industrial Tray Dryer - Metal, Superior Durability & High Quality Performance | Ideal for Various Industrial Applications

Price: 500000 INR/Unit

MOQ1 Unit/Units

UsageIndustrial

MaterialOther, Metal

Spherical Dryer

Price: 200000.00 INR/Unit

MOQ1 Unit/Units

Supply Ability10 Per Week

Delivery Time4-5 Months

Packaging DetailsPacking in corrugated box, shrink wrapping and wooden crates available.

White Hopper Dryer

MOQ1 Piece/Pieces

Product TypeHopper Dryer

ColorWhite

UsageIndustrial

MaterialSteel

Re Blowers India Private Limited

Mumbai

Industrial Rotary Dryer - Voltage: 415 Volt (V)

Price: 510000 INR/Unit

MOQ1 Unit/Units

Temperature200 Celsius (oC)

UsageIndustrial

Fuel TypeGas

Product TypeIndustrial Rotary Dryer

Voltage415 Volt (v)

Mini Spray Dryer - Material: Stainless Steel

Price: 1000000 INR/Kilograms

MOQ1 Piece/Pieces

Weight100- 50000 Kg/ hr Kilograms (kg)

MaterialStainless Steel

Voltage220-240 Volt (v)

Temperatureup to 600 degree Celsius Celsius (oC)

Luftsol Engineering Private Limited

Pune

Lime Sludge Dryer

Price: 50000 INR/Unit

MOQ1 Unit/Units

Supply Ability10 Per Week

Delivery Time15 Days

Whirler Centrifugals Pvt. Ltd.

Ahmedabad

Tray Dryer Machine - Stainless Steel, 415 Voltage | Silver, Industrial Usage

Price: 150000 INR/Piece

MOQ1 Piece/Pieces

Product TypeTray Dryer

ColorSilver

UsageIndustrial

MaterialStainless Steel

Voltage415 Volt (v)

Innovative Engineering Works

Ahmedabad

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller Super Premium

Super Premium Premium Seller

Premium Seller4 Years

Super Premium

Super PremiumBamboo Mat Dryer - Color: Blue

Price: 3000000.00 INR/Piece

MOQ1 Piece/Pieces

Product TypeMat Dryer

UsageIndustrial

ColorBlue

MaterialStainless Steel

Voltage440 Volt (v)

Warranty1 Year

Rotary Drum Dryer - Color: Blue

Price: 1400000 INR/Number

MOQ01 Number

Product TypeRotary Drum Dryer

UsageIndustrial

ColorBlue

MaterialStainless Steel

Compressed Air and Gas Dryer - Mild Steel, 130x140x140 cm, Green Color Coated, 50-120 CFM Flow Rate, 20 kg Weight, Industrial Usage, Moisture Removal and Equipment Protection

Price: 2000.00 INR/Piece

MOQ1 , Number

ColorGreen

Height140 Centimeter (cm)

Width140 Centimeter (cm)

Weight20 Kilograms (kg)

Length130 Centimeter (cm)

Product TypeCompressed Air and Gas Dryer

Gts Filters And Systems (india) Private Limited

Vadodara

Drying System For Conveyor Belt - Automatic Grade: Automatic

Price Trend: 50000.00 - 400000.00 INR/Set

MOQ1 Set/Sets

ColorAs per customer requirement

Ventilation20000 ft3/min (CFM)

MaterialSS/ GI/ MS/ FRP

Frequency50 Hertz (HZ)

Hole SizeAs per customer requirement Millimeter (mm)

Noise Level85 db

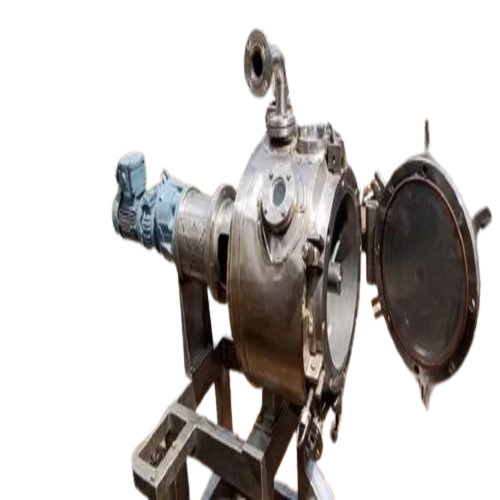

Carbon Steel Rotary Vacuum Dryer

Price: 100000 INR/Unit

MOQ1 Unit/Units

MaterialCarbon Steel

Sunrise Process Equipments Private Limited

Mumbai

Stainless Steel Drum Flaker

Price: 500000 INR/Unit

MOQ1 Unit/Units

Weight4300 Kilograms (kg)

Product TypeDrum Flaker

Usageindustrial

MaterialStainless Steel

Pratham Engineering

Mira Bhayandar

Trusted Seller

Trusted Seller14 Years

Fluid Bed Dryer - Steel Material, Silver Color | Versatile and Hygienic Drying, Fully Automatic Bag Shaking, Safe Earthing Arrangement

ColorSilver

UsageFor Industrial

Product TypeFluid Bed Dryer

MaterialSteel

Electric Papad Dryer Machine - Durable Materials, Grey Color, 2 HP Power | Efficient Uniform Drying, User-Friendly Controls, Ideal for Modern Kitchens

Price: 245000 INR/Piece

MOQ1 Piece/Pieces

UsageIndustrial

Product TypeElectric Papad Dryer Machine

Power2 Horsepower (HP)

ColorGrey

Stainless Steel Industrial Tray Dryer

MOQ1 Unit/Units

Heat SourceElectric

UsageIndustrial

SizeVarious Sizes Available

MaterialStainless Steel

TechnologyNormal

WarrantyYes

Tray Dryers

Price: 100000 INR/Piece

MOQ1 Piece/Pieces

Payment TermsOthers, Cheque

Main Export Market(s)Asia

Main Domestic MarketAll India

Electric Tray Dryer - Material: Stainless Steel

Price: 160000 INR/Unit

MOQ1 Unit/Units

Heat SourceElectric

SizeCustomized

UsageIndustrial

MaterialStainless Steel

TechnologyNormal

Steel Fluidized Bed Dryer

Price Trend: 40000.00 - 80000.00 INR/Unit

MOQ1 , Unit/Units

MaterialSteel

Jicon Technologies Private Limited

Mumbai

Agitated Thin Film Dryer Plant - Material: Stainless Steel

Price: 2000000 INR/Unit

MOQ1 Unit/Units

Product TypeAgitated Thin Film Dryer Plant

UsageIndustrial

Power10 Horsepower (HP)

MaterialStainless Steel

Voltage440 Volt (v)

Warranty1 Year

Rototech Engineering Systems

Ahmedabad

Stainless Steel Industrial Flash Dryers

Price: 500000 INR/Unit

MOQ1 Unit/Units

Heat SourceCoal

UsageIndustrial

Temperature500 Deg C Celsius (oC)

Product TypeFlash Dryers

MaterialStainless Steel

Voltage220-440 Volt (v)

Technodry System Engineering Private Limited

Chakan

Fluid Bed Dryer Machine - Stainless Steel, Standard Size, Silver | Low Maintenance, Easy Installation, Advanced Automation with PLC Control, Energy Efficient Design

Price Trend: 200000.00 - 350000.00 INR/Unit

MOQ1 Unit/Units

Product TypeFluid Bed Dryer Machine

UsageIndustrial

ColorSilver

SizeStandard

MaterialStainless Steel

Voltage220-240 Volt (v)

Ace Industries (india) Private Limited

Mumbai

Fluid Bed Dryer - Color: Silver

Price: 500000.00 INR/Piece

MOQ1 Piece/Pieces

ColorSilver

SizeCustomized

Power Consumption5 TO 100 KW Kilowatt (kW)

Product TypeFLUID BED DRYER

Usageindustrial Use

Temperature50 to 90 Celsius (oC)

Allmach Pharma Machinery Private Limited

Ahmedabad

Continuous Fluid Bed Dryers - Robust Stainless Steel Construction , Efficient Drying Technology for High-Throughput Applications

Price: 40000 INR/Unit

MOQ1 , Unit/Units

Supply Ability1 Per Month

Delivery Time3-2 Week

Silver Nutsche Filter Dryer

Price: 5000000 INR/Piece

MOQ1 , Piece/Pieces

ColorSilver

UsageConstruction

Product TypeNutsche Filter Dryer

SizeSizes Available

MaterialStainless Steel

Voltage220 Volt (v)

Stainless Steel Industrial Fluidized Bed Dryer

Price: 9000000 INR/Unit

MOQ1 , Unit/Units

UsageIndustrial

MaterialStainless Steel

Microtech Boilers Private Limited

Ahmedabad

Latest From Industrial Dryers

Industrial Dryers

By:

Advance Heating Systems

Electric Automatic Industrial Dryers

By:

Bansal Engineers (grain Milling) Private Limited

Drying Systems

By:

Badrin Industries

Industrial Rotary Dryers

By:

R. V. Industries

Rotary Vacuum Dryers

By:

A. S. P. Chem-equipments

Explore More Cities

Ready To Ship Industrial Dryers

An Importance of Industrial Dryer

Introduction

A huge quantity of bulk materials can be dried quickly and efficiently using an industrial dryer. There is a wide variety of industrial dryer types available, each one tailored to a particular kind and quantity of material. Production needs, available facility space, material to be dried, drying process requirements, and final product standards are all taken into account when deciding which dryer is best for a certain application.

How does an industrial dryer work?

The moisture in the hot incoming air is condensed into liquid water by the cold air that is expelled. The air is cooled further with a liquid refrigerant after passing through an air-to-refrigerant heat exchanger. Drying the air in an industrial dryer involves the subsequent steps:

- As warm, humid air is sucked into the dryer, it is immediately cooled to roughly 3 °C (37.4 °F) in a refrigeration unit. The air's water vapor condenses into liquid water at this temperature, which is then collected in a water trap and fed into discharge lines. A condenser is used to recycle the warm, gaseous refrigerant by cooling it.

- Dry air from the chamber is reheated to normal temperature and released through a vent.

As an added bonus, chilled industrial dryers come in two distinct varieties: cycling and non-cycling.

- Dryers that cycle can keep the dew point steady since they operate at 100% capacity.

- Dryers that don't cycle keep the temperature constant by shutting down and starting up at regular intervals.

There are two towers in a desiccant industrial dryer system; one dries the air while the other regenerates the desiccant. When compressed air from the input is passed through the drying tower's porous desiccant material, it is dehumidified. The single-tower desiccant industrial dryer is a less typical variation that uses a singular tower to remove moisture from incoming air. The same is true with single-tower dryers; they don't use electricity, have no moving components, and can be used anywhere. They can be used in places where there is a high risk of fire or corrosion.

Types of Dryers

1. Spray Dryers

The feed, which could be a solution or slurry, is atomized into droplets and sent through a spray dryer to be dried. A large drying chamber, maybe 15 m in diameter and 35 m in height, is its main component. The typical range for the temperature of the hot gas is between 250 and 280 degrees Celsius, while it can reach temperatures of up to 700 degrees Celsius.

2. Fluidized-bed Dryer

This drier is ideal for drying a wide variety of damp, free-flowing solids. The underlying concept is straightforward. A screw feeder constantly introduces the wet solid into the drier, where the flow of hot drying gas maintains a fluidized state for the material. Minerals, fish meals, cereals, spices, seeds, garbage, drugs, and more can all be dried in a fluid-bed dryer.

3. Vacuum Dryer

A heating jacket and a slow-moving agitator are included in the vacuum dryer for drying wet materials. In most cases, a vacuum of around 10 mm Hg is employed. Powders, granules, and hygroscopic substances that are either hazardous or sensitive to heat are dried using the vacuum-drying method.

4. Rotary Dryer

Many different types of continuous dryers are employed in the process industries, but rotary dryers, also known as the "workhorse of chemical dryers," are by far the most common. A cylindrical shell with a modest inclination rotates slowly while being filled with a moist solid from the top. This dryer works well with granular materials that are easy to move about and don't stay together, like sodium sulfate, organic slats, salt, minerals, and ammonium sulfate that have been crystallized and washed.

5. Tray Dryer

If your business uses cross-circulation drying, chances are good that you've used a tray dryer. Drying gas is passed over the visible top surface of a solid spread on a tray, which is achieved by stacking the trays in the drying chamber with a space between them. Steam coils are used to preheat the drying gas (often air). Moisture-laden air is evaporated as it passes through the cabinet and out the exhaust vent. By altering the gas flow rate, the air's temperature, humidity, and velocity can be controlled.

6. Continuous Tray Dryers

Drying plates or trays in continuous tray Industrial Dryers all have the same opening. As the material is loaded into the tray, it is moved from one tray to the next by a sequence of ploughs and heated air.

7. Contact Evaporation Dryers

To hasten the process of evaporation, things are set down on a hot surface.

8. Air Bar Drying

With their ability to evenly distribute drying air, air bar dryers are well-suited for drying and supporting webs of delicate materials that conventional dryers may otherwise damage.

9. Conveyor Belt Drying

The product is loaded onto a perforated belt and transported to a drier. It's possible to dry a product by passing air over it, or by placing a fan underneath it. Multiple zones with varying temperatures are commonly used in such systems.

10. Freeze Dryer

The process of freeze-drying (also called lyophilization) involves putting the item to be dried into a vacuum while it is frozen. It's used for anything that changes form or degrades a lot when heated. The substance retains its original chemical and biological features. It is used to keep the nutrients and medicines in foods and medicines intact. It's also common in things like blood, tissues, and proteins taken from living organisms for study. Freeze-drying, however, is a lengthy process.

11. Bin Dryers

Bin dryers feature a perforated plate at the bottom of a storage bin or tank. A fan forces air through the perforated plate and into the ceiling. Drying occurs as a result of the presence of air around the wet substance. The wettest materials can be stored near the bottom of shelves.

12. Tunnel Dryer

Drying materials are placed on a trolley with trays in a tunnel dryer. As a steady stream of hot air or gas is blasted through the drying tunnel, the trolleys enter at once and move gently in both directions.

Advantages of An Industrial Dryer

1. Time Reduction

To begin, the drying time for cereal can be drastically cut with the help of industrial dryers. Traditional sun drying of beans is still practiced in many parts of the world. However, this approach is labor-intensive, taking weeks or even months, and it lacks precise control over the drying process, making it vulnerable to external factors such as weather. Alternatively, a tower or discontinuous drier may dry the grain in a matter of hours, guaranteeing its safety for long-term storage.

2. Reduction of Losses And Waste

It is for this reason that the use of an industrial grain drier can lessen the amount of wasted product and, by extension, the accompanying monetary losses. By using these methods, you may safely store cereal without worrying about it sprouting or going bad. This eliminates the possibility of losing money due to a wasted harvest. The best way to ensure that the value of the cereal itself is preserved is to dry it.

3. Maximize Profits

It's easy to see how these options help you earn the most money possible; less time and effort spent on inefficient activities means more time spent selling your goods when demand is highest and prices are lowest.

4. Maintains Garments With Vibrant Colors Longer

Dryers allow you to get more clothes done in less time. To have your clothes dry in as little as 40 minutes, use the Fast 40 setting on dryers. In fact, the regular cycle allows you to put away clean garments immediately rather than waiting a day or two.

5. Protects Clothes From Dust And Odor

The sun's UV rays can bleach the colors out of your favorite garments if you leave them out in the wet in the sun. But modern Heat Pump technology gives precisely the amount of heat required to keep your garments looking as good as new.

6. Dry Your Delicates With Care

To keep their original condition, some materials require special maintenance. The Delicate system provides gentle drying for even the most delicate fabrics, from everyday cotton to silk and wool. Each cycle's temperature and action prevent your clothes from shrinking and losing their form, ensuring that they always look as refined and sophisticated as the day you bought them.

FAQs: Industrial Dryer

Q. Is an industrial dryer worth it?

Ans. Yes, you should just buy the right industrial dryer with a good investment strategy. The industrial buyer is between Rs 50,000- 5 lakhs in India.

Q. Do industrial dryers use a lot of electricity?

Ans. Depending on the size of the load and how much water or moisture is on the clothes, the average washing machine will use between 1.4 and 4-kilowatt hours (or units) of electricity.

Q. Can I use an industrial dryer at home?

Ans. Yes, Of course, anyone can use an industrial dryer or washer at home.

Q. Do industrial dryers dry faster?

Ans. The speed of an industrial dryer is under 20 minutes depending on the weight or size of the dryer. Overall, you can get dry clothes in under 20-25 minutes.

Manufacturers & Suppliers of Industrial Dryers

Company Name | Member Since |

|---|---|

Dipesh Engineering Works Mumbai, India | 23 Years |

Sunrise Process Equipments Private Limited Mumbai, India | 22 Years |

Jicon Technologies Private Limited Mumbai, India | 22 Years |

B S Engineering Machinery Pvt. Ltd. Kolkata, India | 21 Years |

Whirler Centrifugals Pvt. Ltd. Ahmedabad, India | 20 Years |

United Air Tech Industries Mumbai, India | 17 Years |

Bry-Air (Asia) Pvt. Ltd. Gurugram, India | 16 Years |

P-Square Technologies Pune, India | 16 Years |

Re Blowers India Private Limited Mumbai, India | 15 Years |

Ace Industries (India) Private Limited Mumbai, India | 15 Years |

Popular Products