Vibrating Screen

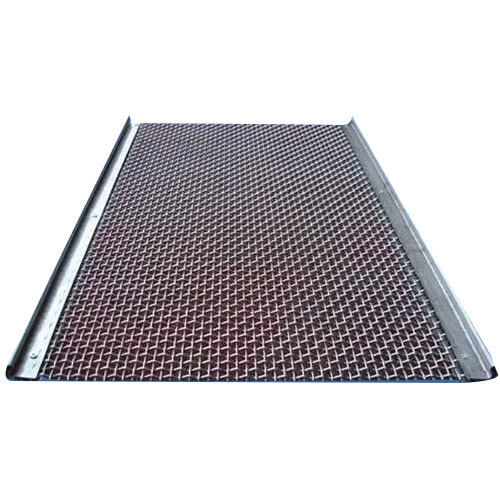

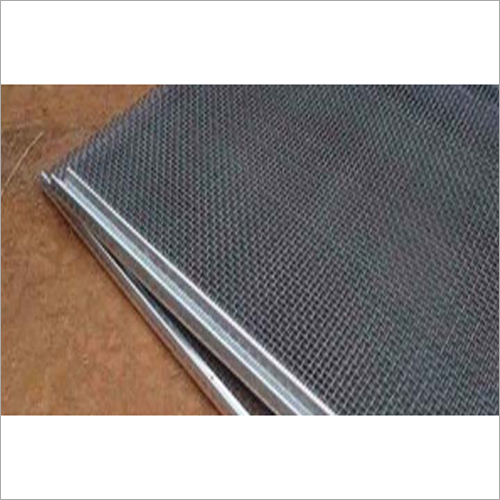

(1537 products)Vibrating Screen Cloth - Length: 0.5-12 Millimeter (Mm)

100 INR (Approx.)/Square Foot

MOQ200 Square Foot/Square Foots

Length0.5-12 Millimeter (mm)

UsageIndustrial

SizeStandard

Product TypeVibrating Screen Cloth

Mesh TypeIron Wire Mesh

Mesh StyleCrimped Wire Mesh

Circular Vibrating Screen - Stainless Steel, New Electric Power Mode | High Capacity, Multi-Directional Vibration System, Ideal for Industrial Size Separation

MOQ1 Piece/Pieces

Product TypeCircular Vibrating Screen

UsageIndustrial

MaterialStainless Steel

ConditionNew

ShapeCircular

Power ModeElectric

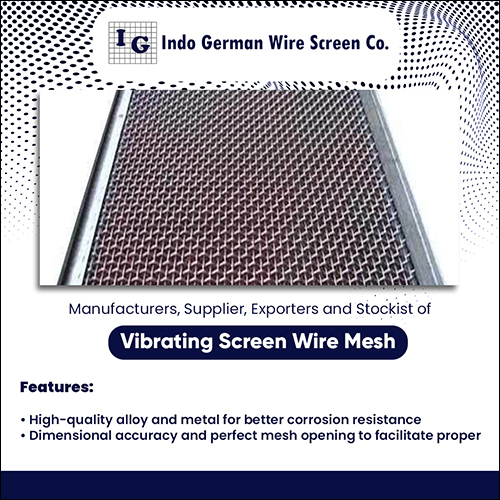

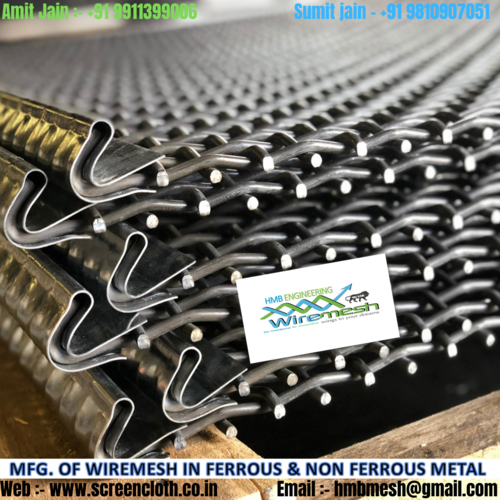

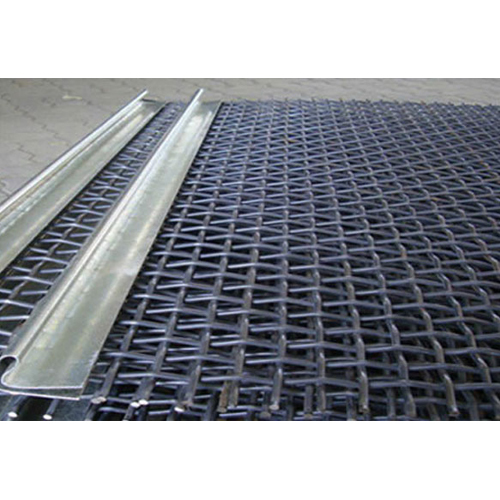

Vibrating Screen Mesh - Pre-Crimped Manganese Steel & Stainless Steel, Customizable Sizes for Enhanced Strength

40 INR (Approx.)/Piece

MOQ100 Square Foot/Square Foots

Supply Ability1000 Per Week

Delivery Time2-7 Days

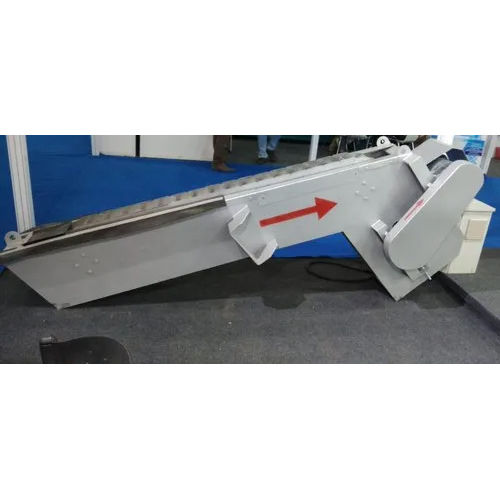

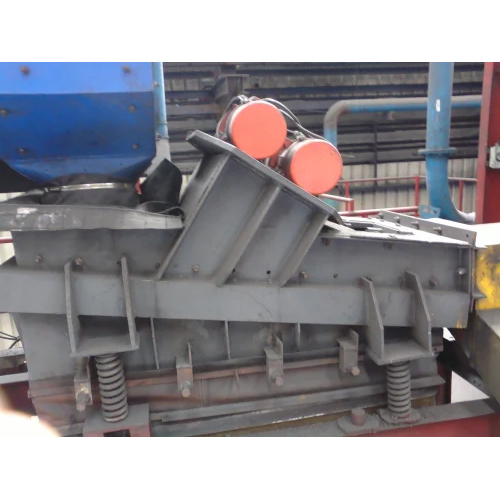

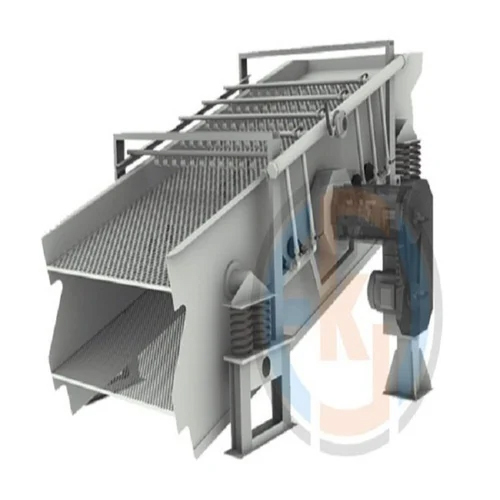

Circular Motion Vibrating Screens - Application: Industrial

Price: 2500000 INR/Unit

MOQ1 Unit/Units

Weight2000 Kilograms (kg)

TypeOther

MaterialCarbon Steel

Processing TypeStandard

ConditionNew

Power ModeElectric

Stainless Steel Ultrasonic Screen Separator - Size 2-500 Inch, Silver Color | Electric Power Mode, Standard Processing, Circular Shape, 220V Voltage

Price: 185000 INR/Unit

MOQ1 Unit/Units

ColorSilver

Product TypeUltrasonic Screen Separator

SizeCustomized

MaterialStainless Steel

Processing TypeStandard

ConditionNew

Vibrating Screen Mesh Application: For Industrial

Price: 185 INR/Square Foot

MOQ10 Square Foot/Square Foots

TypeOther, Vibrating Screen

MaterialStainless Steel

ShapeSpiral

ApplicationFor Industrial

Tumbler Screen - Stainless Steel, 7 Ton Capacity | Automatic Industrial Automation, Low Noise Operation Under 75DB

Price: 650000.00 INR/Piece

MOQ1 Piece/Pieces

Product TypeTumbler Screen

TypeOther, Tumbler Screen

MaterialOther

ConditionNew

ApplicationIndustrial

Coating TypePainted

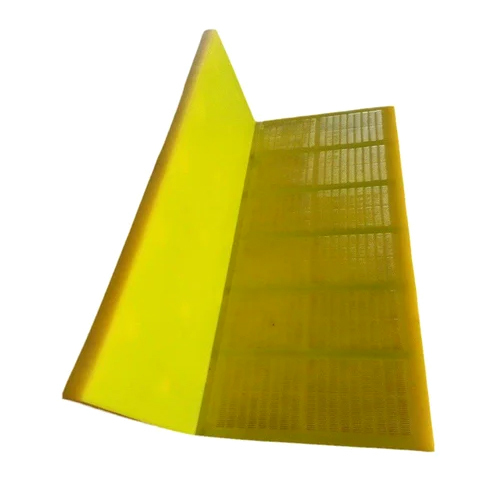

Yellow Vibrating Screen

MOQ1 Unit/Units

ColorYellow

SizeStandard

TypeOther, Vibrating Screen

Equipment TypeVibrating Screen

MaterialStainless Steel

ConditionNew

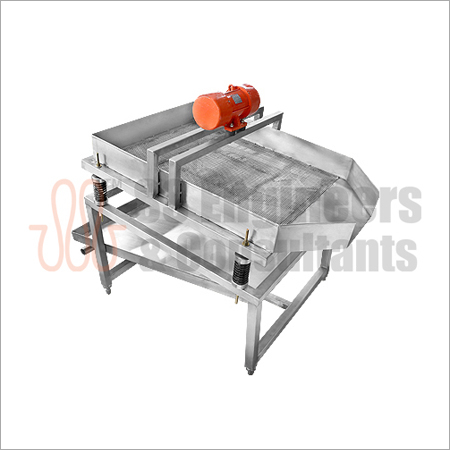

Vibrating Screen - Stainless Steel, 500-1000 Weight | New Condition, 220-240 Voltage

Price: 100000 INR/Unit

MOQ1 Unit/Units

Weight500-1000 Kilograms (kg)

TypeVibrating Screen, Other

MaterialStainless Steel

ConditionNew

Voltage220-240 Volt (v)

Moderate Machines (pvt.) Ltd.

Jaipur

Trusted Seller

Trusted Seller14 Years

Mechanical And Menu Bar Screen - Color: White

Price: 200000 INR/Unit

MOQ1 Unit/Units

ColorWhite

Product TypeMechanical And Menu Bar Screen

UsageIndustrial

MaterialStainless Steel

ConditionNew

Power ModeElectric

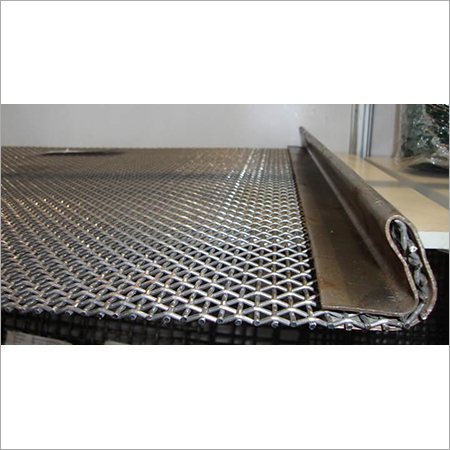

Dovex Screen Mesh - Acid, Alkali, Heat Resistant | Durable Flat Working Surface, Consistent Mesh Openings

Price: 40 INR/Piece

MOQ100 Square Foot/Square Foots

Supply Ability1000 Per Week

Delivery Time2-7 Days

International Wirenetting Industries

Palghar

Centrifugal Rotary Screen Capacity: 300-500 Kg/Hr

Price: 50000 INR/Unit

MOQ1 Unit/Units

TypeGravity Separator

MaterialStainless Steel

Processing TypeStandard

ConditionNew

Capacity300-500 Kg/hr

Power ModeElectric

Circular Vibrating Insect Screen - Stainless Steel, Standard Size, Silver | Self-Cleaning Structure, Less Noise, High Output, Long Life

MOQ100 , Piece/Pieces

UsageIndustrial

SizeStandard

Product TypeCircular Vibrating Screen

ColorSilver

MaterialStainless Steel

ConditionNew

Vibrating Screen - High-Quality Design , Smooth Operations & Long Functional Life

Price: 20000 INR/Unit

MOQ1 Piece/Pieces

Supply Ability1 Per Week

Delivery Time3-2 Week

Main Export Market(s)Australia, South America, Middle East, Africa, Western Europe, Asia, Central America, Eastern Europe, North America

Centrifuge Extractor - Durable Stainless Steel | High Efficiency, Precision Extraction Technology, Compact Design

Price Trend: 120000.00 - 180000.00 INR/Number

MOQ1 Number

TypeOther, Centrifuge Extractor

MaterialStainless Steel

Processing TypeContinuous, Other

ConditionNew

ShapeOther, Cylindrical

Capacity50 liters

Ms Vibrating Screens - Capacity: 10 T/Hr

UsageIndustrial

Product TypeMS Vibrating Screens

MaterialOther, MS

ConditionNew

Capacity10 T/hr

Power ModeElectric

Goldin (india) Equipment Pvt. Ltd.

Vadodara

SS Vibro Screen - Stainless Steel, 0.4 Spatial Requirement | Automatic Electric Drive, High Screening Capacity, Eco-Friendly, Easy to Install

Price: 75000 INR/Unit

MOQ1 Unit/Units

Product TypeVibro Screen

MaterialStainless Steel

AutomaticYes

Drive TypeElectric

Voltage220 to 415 Volt (v)

Destiny Solution And Engineers

Ahmedabad

Vibrating Screen

Price Trend: 5000.00 - 10000.00 INR/Piece

MOQ10 Piece/Pieces

Supply Ability100 Per Day

Delivery Time7-10 Days

Dewatering Vibrator Screen

Price Trend: 100000.00 - 550000.00 INR/Unit

MOQ1 Unit/Units

Supply Ability10 Per Month

Delivery Time1 Week

Ss Engineers And Consultants Private Limited

Rajahmundry

Vibratory Screen - High-Quality Raw Material, Long Functional Life | Customizable Features and Specifications

Product DescriptionOur vast industry experience of manufacturing and supplying a broad gamut of vibratory screens. Fabricated from quality raw material, it is known for its longer functional life. Our range is easily gettable at various types of demanded features and specifications

Woven Wire Screen Cloths - Color: Grey

Price: 70500 INR/Square Foot

MOQ50 Kilograms/Kilograms

ColorGrey

Product TypeWoven Wire Screen Cloths

UsageIndustrial

MaterialStainless Steel

ConditionNew

Metal Vibrating Screens - Color: Silver

Price: 1300 INR/Roll

MOQ1 , Square Foot/Square Foots

UsageIndustrial

ColorSilver

Product TypeMetal Vibrating Screens

TypeOther, Vibrating Screen

MaterialOther, Metal

Processing TypeOther, Vibrating

Sorter Industrial Vibrating Screen

Price Trend: 5000.00 - 10000.00 USD ($)/Set

MOQ1 Set/Sets

Product TypeVibrating Screen

UsageIndustrial

TypeSorter

ConditionNew

Zhejiang Meibao Industrial Technology Co., Ltd.

Hangzhou

Industrial Vibrating Screen Mesh - Material: Carbon Steel

MOQ10 Kilograms/Kilograms

Product TypeScreen Mesh

UsageConstruction

MaterialCarbon Steel

ConditionNew

ApplicationIndustrial

Industrial Vibrating Separator - Stainless Steel, Standard Size, Silver | New Electric Power Mode, Customized Processing Type

Price: 80000 INR/Unit

MOQ1 Unit/Units

Product TypeIndustrial Vibrating Separator

ColorSilver

UsageIndustrial

SizeStandard

MaterialStainless Steel

Processing TypeCustomized

Steel Vibrating Screen Processing Type: Standard

Price: 260 INR/Kilograms

MOQ100 Kilograms/Kilograms

UsageIndustrial

MaterialStainless Steel

Processing TypeStandard

ConditionNew

Power ModeManual

Vibrating Screen - Capacity: 10-300 T/Hr

Price: 300000.00 INR/Unit

MOQ1 Unit/Units, Unit/Units, Unit/Units

ColorBlue

Length8-20 Foot (ft)

Width4-6 Foot (ft)

Product TypeSand Screening

UsageFor Sand vibratory Screening

General UseSand Making

Gulmohar Fil-tech Private Limited

Indore

Multi Rake Fine Bar Screen - Application: Industrial

MOQ1 Piece/Pieces

ColorWhite And Blue

UsageIndustrial

Product TypeMulti Rake Fine Bar Screen

SizeStandard

TypeOther, Multi Rake Fine Bar Screen

MaterialStainless Steel

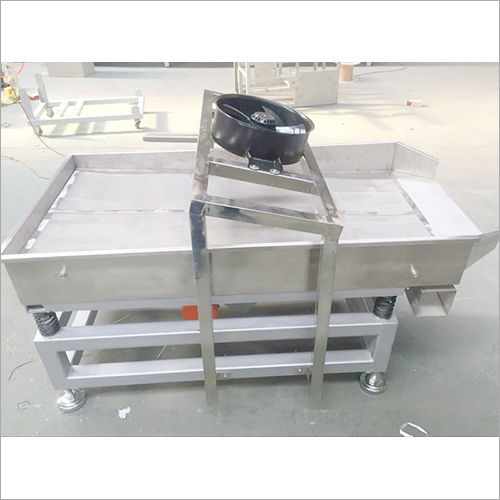

Industrial Vibro Shifter Processing Type: Standard

Price: 30,000 INR/Piece

MOQ1 Piece/Pieces

Product TypeIndustrial Vibro Shifter

SizeNormal

TypeWasher

MaterialOther, Mild Steel

Processing TypeStandard

ConditionNew

Bhagirath Engineering Works

Kolkata

Indoor Led Display

Price: 65000 INR/Square Foot

MOQ10 Square Foot/Square Foots

Supply Ability1000 Per Month

Delivery Time7 Days

Vibrating Screen

MOQ1 Sheet/Sheets

Payment TermsCash on Delivery (COD), Others, Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

Supply Ability5 Tones Per Month

Delivery Time1 Week

Hindustan Industrial Corporation

Mumbai

Latest From Vibrating Screen

Industrial Vibrating Screen Mesh

By:

Shankar Weldmesh Private Limited

Industrial Vibrating Screen

By:

Ksk Engineers

Industrial Vibrating Screen

By:

Global Associate

Industrial Vibrating Screen

By:

Manjas Mart

Explore More Cities

Ready To Ship Vibrating Screen

Vibrating Screen: Work and operation

Vibrating screens supplied by us are advanced quality mechanical equipment, which makes use of vibrating screen pieces to organize the mixture that has been included with different particles. Supplied screens have been engineered to improve and resolve several product handling challenges. The typical application of the screens is the removal of oversized material. The screens are used to classify and separate the particles in different sizes. The basic principle of the screens is the vibration made by the screen's eccentric, driven by a motor.

Vibratory screens are one of the main types of industrial screening equipment. The mechanical screening solutions find applicability for recycling, solid waste management, and aggregate industries. The said screens are of several unique advantages which make them the first-line option for numerous industrial applications.

Operation

During the operation of vibrating screens, the vibration is exposed to the screen to make an effect on the solid particles’ separation, into two size segments. Due to the given vibrations, the solid particles stay in moving conditions. Appropriate selection of frequency as well as amplitude assist in keeping the capacity of screens firm and constant.

Irrespective of the machine’s structure and design, the principle of vibrating screens remains the same. The quivering motions break the surface tension occurring between two particles, enabling an effective separation. Undersized particles go through the surface of the screening and the oversized particles are passed over the surface of the Vibrating screen. The aforementioned is a highly important application in many industries, mainly mineral processing.

Features of Vibrating Screens

Some of the features have been mentioned below;

- Adjustable to the workflow of a sector, with the choice of linear or elliptical drive.

- Performance uptime can be augmented by the arrangement of less maintenance and the system’s rough construction.

- Compatible with several deck types as well as systems.

- The angle as well as the motor of the units can be adjusted to suit the specific requirements of different processes.

- Sizes and design variations are available to fulfill the assorted demands of several applications.

Different Types of Vibrating Screens

Linear Vibrating Screens- This is a special type of vibrating screen which makes use of double vibrating motors which makes rotation in synchronous and opposite directions. It makes a horizontal force that enables the screen to make move in a straight line.

SS Vibro Screen- It is a round-shaped unitary gyratory screen, which has been made to detach the mass arrangement of solids from the liquid as well as solids. This screening machine allows for the advanced gradation of materials and finds utility in different applications.

Dewatering Vibrator Screen- Dewatering screens have a design of linear vibrating devices and assist in the drainage of plastic pellets, kieserite, limestone, sand, etc. It has been made to set off the insoluble impurities from carrier liquids and wash waters.

Centrifuge Extractor- It runs on the principle of centrifugal forces so as to get an effective screening of granular materials, powders, etc.

Stainless Steel Ultrasonic Screen Separator- It functions with the help of an Ultrasonic gyratory screen separator which makes tandem with vibrating action so as to provide solid waste retention. It is useful for dyeing, manufacturing, and refining components.

Circular Vibrating Screen- It is a completely new type of screen that has been equipped with a high-efficiency and multi-layer screen. The said screen has been made to perform operational tasks in an efficient and quick way. It has a seat-type structure which allows for easy adjustments.

Elliptical Vibrating Screen- This is a special type of vibrating screen, included with an elliptical motion track. It is of advanced screening operations and boasts of its ability to put up a larger capacity, demanding greater operations in mines, quarries, and screening operations.

High-Frequency Vibrating Screen- It is one of the best screens which can effectively segregate wet or dry assorted raw materials. It has wide applicability in the mineral processing industry. Featured with a high-frequency screen, pulp distributor, suspension spring, screen frame, etc., it can perform several tasks.

Inclined Vibrating Screen- This special Vibrating screen is applicable for processing quarry, demolition waste, mine, screening gravel, recycling construction materials, etc. It has been equipped with assorted options, such as self-cleaning screens, piano wire screens, woven screens, welded screens, perforated plate screens, needle screens, etc.

Horizontal Vibrating Screen- It is available with the benefits of exceptional screen permeability, linear vibrating screens, low installation height requirements, high processing capacity, etc.

Banana Vibrating Screen- It features a screen plate, various dip angles, and multiple sections, for advanced operational efficacy. This vibrating screen is banana-shaped.

The said screen is helpful in the classification of medium and large-sized materials. It can deal with a high fine particle content and is suited for the processes of demineralization, dehydration, and de-sliming.

Applications of Vibrating Screens

Vibrating screens have a pivotal role in industrial screening tasks. There are several options available on these screens. Supplied material handling systems are helpful in the recycling, waste management, and aggregate industries. The screens are the most preferred methods in the following industries;

• Food Industry.

• Pharmaceuticals.

• Mining

• Chemical Industry.

• Oil Industry.

• Rubber Industry

• Agro Products Manufacturing Industry.

• Mineral Processing Plants.

Top companies of Vibrating Screen

The popular companies dealing in Vibrating screens are named below:

- Uma Engineering

- Aesha Projects

- Ecoman

- Mitool Equipments

- People International

- Russell Finex

- SWECO

- Techno talent

- Vibeng Solutions

FAQs: Vibrating Screen

Q. What are the exclusive benefits of using a Vibrating Screen?

Ans. The vibrating screens have many unique design features, and as a result, the screen delivers specific benefits over other material processing equipment, including:

Lower functional costs- The operation of the screens costs low as they have a simple mechanism and need less maintenance. Dissimilar to complex machines, these screening machines run with lower energy consumption.

Improved material quality and advanced material processing- The said screens are better suited for assorted materials and provide the best quality in the processing of aggregate and mining. Moreover, the machines enable simpler product recovery, higher yields, and enhanced final product quality.

Negligible maintenance and downtime- The machines do not need frequent maintenance and interruption, allowing for advanced productivity as well as high profit. The machines can evade the occurrence of wear and tear, due to their robust make. Higher frequency vibrations can be sent to the screening surface and it will also save on maintenance and repair costs.

Advanced screening efficiency- The vibrating screens with high frequency can attain a high efficiency of separation and is quite different from their main counterparts as they can break down the surface tension. By making a reduction in the screen blinding, the screening efficiency, as well as production rate, can be increased.

Low Noise: The vibrating screens provide a quiet operation, making reduction in noise pollution. These screens are best to use in settings where minimum noise levels are a must.

Q. What is the normal cost of a vibrating screen?

Ans. The normal cost of a Vibrating screen is between 5000.00 - 10000.00 INR (Approx.). The exact price may differ based on the location, brand, and screen type.

Q. How can I improve the performance of my vibrating screen?

Ans. The efficiency of the vibrating screens can be increased in different ways.

-Increase the vibrating screen’s frequency: It can be done by making some adjustments in the motor’s eccentric weights as well as by mounting a higher frequency motor.

-Increase the screen deck’s angle: The screen deck’s angle can be attuned to boost production capacity. With a steeper angle, the material can travel faster and result in high capacity.

-Increase the vibration extent of the vibrating screen: By making a rise in amplitude will make an impact on the amount of material’s kinetic energy.

-Make use of high-performance screen media: With top-quality screen media, a high amount of material can pass through the screen, that too very quickly. This very process can boost capacity.

-Modification in stroke: Adjusting the screen’s stroke can make a commendable difference. Yes, it can substantially boost the production capacity of vibrating screens.

-Conduct consistent maintenance and inspection: With the right and mindful maintenance, good working conditions can be well maintained.

It is recommended to get a balance between capacity and efficiency. So, it is quite important that you conduct testing and simulations for determining the optimal settings for a particular application.

Q. What are the criteria for selecting the right vibrating screen for my application?

Ans. The vibrating screens are heavy-duty mechanical equipment, which performs the tasks of separation, dewatering, grading, dedusting, etc. Before you buy one, be mindful of the below points:

-Determine the opening of the vibrating screen, as it affects the overall functional efficiency of the material separation procedure.

-Check the shape of the particle- Be sure about what materials will pass through the machine, as it will affect the selection of the vibrating screen.

-Density of material- The bulk amount handled by the machine must be in your knowledge, so as to boost the maximum efficiency.

-Distribution of material- You should be aware of, what percent of the material is being used so that they can be distributed accordingly for the screening process.

Manufacturers & Suppliers of Vibrating Screen

Company Name | Member Since |

|---|---|

Siddharth Engineering Co. Navi Mumbai, India | 24 Years |

International Wirenetting Industries Palghar, India | 21 Years |

Jas Enterprise Ahmedabad, India | 21 Years |

Hmb Engineering Ghaziabad, India | 17 Years |

P-Square Technologies Pune, India | 16 Years |

Ecoman Vadodara, India | 15 Years |

K-Pack Systems Private Limited Bengaluru, India | 15 Years |

Hindustan Industrial Corporation Mumbai, India | 15 Years |

Moderate Machines (Pvt.) Ltd. Jaipur, India | 14 Years |

Force Magnetics Vadodara, India | 12 Years |

Popular Products