Biscuit Making Machinery

(226 products)Gray Biscuit Making Machine

MOQ1 Piece/Pieces

Product TypeBiscuit Making Machine

General UseIt is used for making biscuits

MaterialStainless Steel

TypeAutomatic Confectionery Machine

ComputerizedNo

AutomaticYes

Silver Biscuit Making Machines

Price Trend: 200000.00 - 2000000.00 INR/Piece

MOQ1 Piece/Pieces

Product TypeBiscuit Making Machines

MaterialStainless Steel

TypeHard Biscuit Making Machine, Soft Biscuit Making Machine, Sandwich/Wafer Biscuit Machine, Corn Biscuit Making Machine, Cookie Making Machine

Final ProductsMulti-Vitamin Biscuit

ComputerizedNo

AutomaticNo

Two Lanes Biscuit Sandwiching Machine

Price Trend: 40000.00 - 50000.00 USD ($)/Set

MOQ2 Set/Sets

Supply Ability100 Per Month

Delivery Time80 Days

Shanghai Fude Machinery Manufacturing Co., Ltd.

Shanghai

Reliable Biscuit Machinery

Product DescriptionBeing a customer centric organization, we are involved in manufacturing, exporting and supplying a supreme quality range of Reliable Biscuit Machinery in Mumbai, Maharashtra, India. Biscuit Machinery are providing by us those are made by latest method with latest technology. Client purchase these ma

Biscuit Making Hard Dough Machine Without Laminator

Price: 10000000 INR/Unit

MOQ1 Unit/Units

Final ProductsHard Biscuit

Size Of BiscuitOther

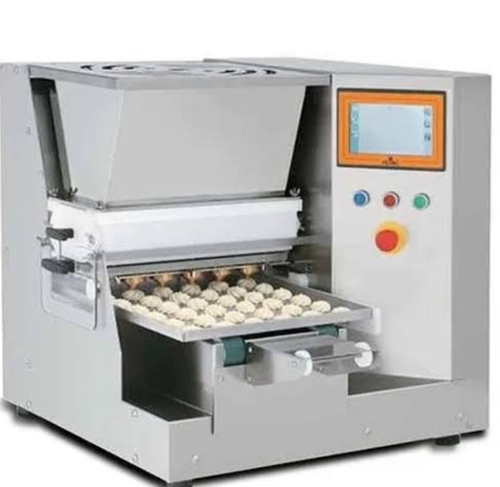

Cookie Twin Depositor

Price Trend: 1750000.00 - 1750000.00 INR/Piece

MOQ1 Piece/Pieces

Colorgrey

Product Typeautomatic

General Usecookies

Materialss

Weight (kg)700 Kilograms (kg)

TypeCookie Making Machine, Other

Complete Crisp Biscuit Production Line - Additional Ingredient: Packing Machines

Price: 9555555 INR/Unit

MOQ1 Unit/Units

ColorSilver

Product TypeComplete Crisp Biscuit Production Line

General UseCrisp Biscuit Making

Additional IngredientPACKING MACHINES

MaterialStainless Steel

FormSolid

Zhengzhou Kingdoo Machinery Co., Ltd.

Zhengzhou

Cream Hopper Machines - Color: Silver

MOQ10 Unit/Units

Product TypeCream Hopper Machines

General UseIndustrial

MaterialStainless steel

TypeOther

ComputerizedNo

AutomaticYes

Biscuit Making Plant - Capacity: 50 Kg/Hr

Price: 9000000 INR/Piece

MOQ1 Piece/Pieces

Product TypeBiscuit Making Plant

General UseBakery

MaterialSS

Capacity50 Kg/hr

AutomaticYes

Metal Biscuit Making Machine

Price Trend: 175000.00 - 1000000.00 INR/Unit

MOQ1 Unit/Units,

General UseFor Biscuit Making

MaterialMetal

TypeHard Biscuit Making Machine, Soft Biscuit Making Machine

ComputerizedYes

AutomaticYes

Baking SourceElectric

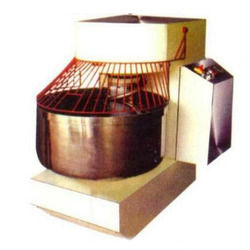

Biscuit Dough Spiral Mixer

Product DescriptionOur customers can avail these Biscuit Dough Spiral Mixers in various sizes and specification. We make sure that the highest quality raw materials are used in the manufacturing of these Biscuit Dough Spiral Mixers. Our these products are widely appreciated by our customers for its quality and durabil

Cookies Biscuit Making Machine - General Use: Industrial

Price: 5000 USD ($)/Set

MOQ1 Set/Sets,

Product TypeBiscuit Making Machine

General UseIndustrial

MaterialSS

AutomaticYes

Voltage220-240 Volt (v)

Warranty1 year

Shanghai Junyu Food Machine Co,.ltd.

Shanghai

Wafer Biscuit Making Machine

Product DescriptionOur company has designed & developed a very compact manual Wafer Biscuit Machine that is suited for the production of Wafer Cream Biscuit. This manually operated plant is very simple & very economical to operate. One worker can operate upto 3 wafer Tongs.\015\012\015\012The batter is infused by mean

Wafer Machine - Manual

Product DescriptionWT Series cream wafer plants are used for the manually operated production of cream wafer biscuits. They are characterized by simple mechanism study and flexibility. These machines are low cost and economical in operation. Depending on the output required they can be supplied with 6, 9 or 12 Wafer

Biscuit Dropping Machine

Price: 680000 INR/Piece

MOQ1 Piece/Pieces

ColorSilver

Product TypeBiscuit Dropping Machine

MaterialStainless Steel

Capacity400 Kg/hr

TypeCookie Making Machine

ComputerizedYes

Modern Baking Equipments

Ranga Reddy district

Biscuit Plant - Material: Brass

Price: 1200000 INR/Piece

MOQ1 Piece/Pieces

ColorSilver

Product TypeBiscuit Plant

General Usebiscuit

MaterialStainless Steel

TypeSoft Biscuit Making Machine

Final ProductsCalcium Biscuit

Barley Biscuit - Oven Type: Electric Oven

Price: 120 INR/Pack

MOQ500 Pack/Packs

Product TypeBarley Biscuit

MaterialBarley

TypeCookie Making Machine

Final ProductsCalcium Biscuit

Size Of BiscuitLong

ComputerizedNo

High Speed Cookie Wire Cut Machine 2, Motor Power: 2-3 HP

Product DescriptionHigh Speed Cookie Wire Cut Machine

5 Nozzle Cookie Dropping Machine - High-Quality Stainless Steel, Efficient Automatic Dosing System | Professional Testing for Optimal Performance

Price: 500000 INR/Unit

MOQ01 Unit/Units

Product DescriptionBiscuit Making Machine

Biscuit Machine - Color: White

Price: 450000 INR/Piece

MOQ1 Piece/Pieces

ColorWhite

Product TypeBiscuit Machine

General UseIndustrial

MaterialStainless steel

Weight (kg)120 Kilograms (kg)

Final ProductsMulti Grain Biscuit

Biscuit Processing Line - Adjustable Core Injection from 5g to 20g | Custom Core Head for Optimal Injection Effect

Product DescriptionWe are reputed enterprises in this industry, manufacturing and supplying Biscuit Processing Line in Chinchwad, Maharashtra, India. The device can be used for chocolate, egg yolk, bread, cake, pie, note core puffs and other kinds of core food Core injection rate adjustable from 5 grams to 20 grams,

Proveg Engineering & Food Processing Private Limited

Pune

High Speed Cookie Wire Cut Machine, Power Source: Electric

Product DescriptionHigh Speed Cookie Wire Cut Machine

Biscuit Making Machinery

Price: 200000 INR/Piece

MOQ1 Piece/Pieces

Product TypeBiscuit Making Machinery

Shanghai Qh Bake Food Machine Co,. Ltd.

Shanghai

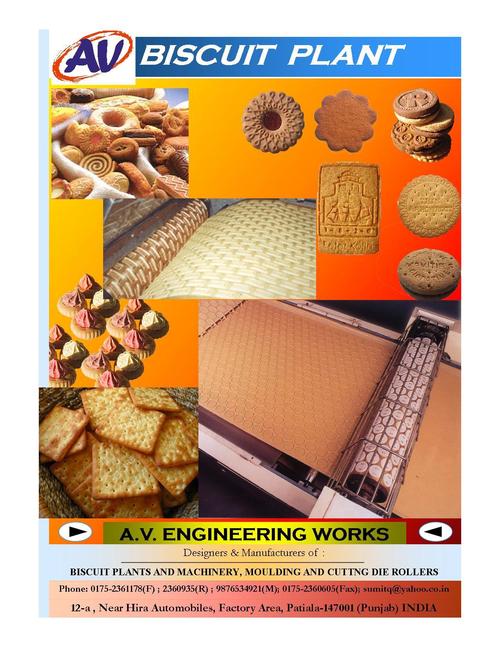

Biscuit Plant - High-Tensile Stainless Steel Design | Superior Hygiene for Soft and Hard Dough Biscuit Production

Product DescriptionThe Biscuit Plants manufactured by us are especially designed for the purpose of making\015\012* Soft Dough Biscuits\015\012* Hard Dough Biscuits\015\012We are using high-tensile stainless steel parts such as contact parts, covers, hoppers and trays in our construction to maintain superior hygienic

Biscuit Making Machinery 6, Phase: Three Phase, Single Phase

Product DescriptionBiscuit Making Machinery

Multi Grain Cookies Application: Commercial

Product DescriptionRs 50 / PackGet Latest Price Brand 7 Star Bakery Flavor Sweet Type Advanced Packaging Size Advanced Ingredients Sugar Baked Good Is It Eggless Non Eggless Storage Good

New Company- Rajkishore Giri

Bhubaneswar

220-Volts Rotary Cutter Stainless Steel Manual Multigrain Biscuit Dropping Machine

Price: 475000 INR/Unit

MOQ1 Unit/Units

ColorSilver

Product TypeBiscuit Dropping Machine

General UseBiscuit Dropping

MaterialMild Steel

Capacity200 Kg/hr

TypeSoft Biscuit Making Machine, Hard Biscuit Making Machine

Precisely Designed Biscuit Making Machine Capacity: 50~1000 Kg/Hr

Price Trend: 9998.00 - 48000.00 USD ($)/Set

MOQ1 Set/Sets

Product TypeAutomatic

General Usebiscuit cookie cracker producing

MaterialStainless steel

Capacity50~1000 Kg/hr

Weight (kg)1~10 Long Ton

Final ProductsMulti Grain Biscuit

Jinan Delon Machinery & Equipment Co., Ltd.

Jinan

Latest From Biscuit Making Machinery

Biscuit Making Machinery 6

By:

Hindustan Enterprises

Biscuit Making Machinery 4

By:

Empire Bakery Machines Pvt.ltd

Biscuit Making Machinery with Rotary Cutter Type with Gas Oven

100000.00 INR

By:

Ananta Engineerings Pvt. Ltd.

Sunder Biscuit Making Machinery

By:

Sunder Industries

ADBAKE Biscuit Making Machinery

By:

Adbake Systems

Four Base Wheeled and Electric Powered GOODTECH Biscuit Making Machinery

300000.00 INR

By:

Goodtech Technologies

Explore More Cities

Ready To Ship Biscuit Making Machinery

Intro - Biscuit Making Machinery

Welcome to the world of biscuit manufacturing equipment, where technological advancement and creativity have completely changed the way we make these delicious delights. The term "biscuit-making machinery" refers to a broad category of specialized machinery used by bakeries, confectioneries, and food manufacturing businesses all over the world to improve and expedite the manufacture of biscuits.

You can achieve consistent quality, accuracy, and efficiency at every stage of the biscuit production process with the help of biscuit-making machines. This cutting-edge equipment automates and optimizes numerous activities, from mixing the dough through shaping, cutting, baking, and packing, assuring a smooth and uniform manufacturing line. Biscuit manufacturing equipment offers flexible options that may be adjusted to your particular recipe requirements, whether you are trying to manufacture traditional buttery pleasures, crispy cookies, or savory crackers.

Benefits of Using Automated Biscuit Making Machinery

Automated biscuit manufacturing equipment has greatly improved the food sector by simplifying the production of biscuits and providing several advantages. First off, the productivity and efficiency of these cutting-edge equipment are greatly increased. They can easily combine the ingredients, form the dough, and cut biscuits into the desired shapes using their automated functions. This improves the overall quality of the product by ensuring uniformity in the size, texture, and look of the cookies while also saving crucial time. Businesses may increase their productivity and efficiently fulfill rising customer needs by doing away with the necessity for manual labor-intensive processes like rolling and cutting.

The improved cleanliness and food safety that automated biscuit-making equipment offers is another major benefit. These devices include easy-to-clean components and stainless steel surfaces since they were created with hygiene and sanitation in mind. Automated equipment contributes to upholding strict standards of food safety by minimizing human touch with the dough and lowering the possibility of contamination. Furthermore, these devices frequently have cutting-edge monitoring systems that guarantee accurate temperature control, cooking durations, and quality checks, ensuring dependably tasty and safe biscuits. This helps firms follow strict regulatory norms and guidelines while also fostering consumer trust.

Types of Biscuit Making Machinery Available

There are many different types of biscuit-making equipment on the market, all of which are made to meet certain demands and specifications for manufacturing. The dough mixer is one kind that is frequently used and is crucial for effectively combining materials and producing a uniform dough texture. Businesses may select the mixer that best meets their production volume because it is available in a variety of sizes and capacities. They have strong motors and sturdy mixing blades that guarantee complete and consistent mixing, producing wonderfully mixed biscuit dough.

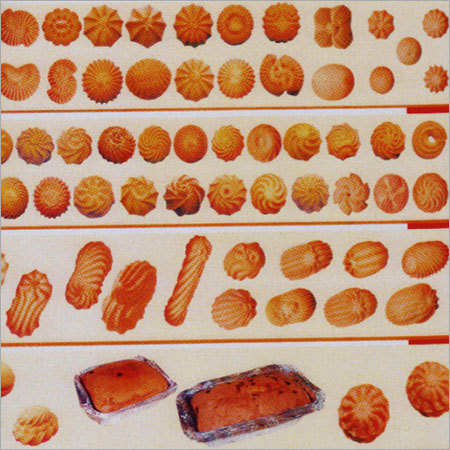

The dough sheeter is yet another common piece of biscuit-making equipment. The dough is rolled out using this machinery to the correct thickness before being cut into individual biscuit shapes. Both manual and automatic dough sheeters are offered. While automated sheeters use conveyor belts and adjustable rollers to speed the operation, manual sheeters need some physical effort from the operator to feed and roll the dough. These devices not only help you save time and labor, but they also provide you perfect control over the dough's thickness, guaranteeing uniform biscuit sizes and textures. In addition, there are specialist biscuit cutters that are available. These include rotary cutters, wire-cut machines, and rotary molders.

Key Components of Biscuit Making Machinery

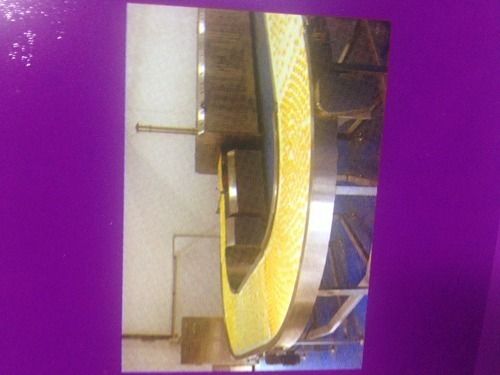

When it comes to baking biscuits, a number of essential equipment components work together in harmony, increasing production efficiency and guaranteeing top-notch product quality. Among these fundamental components, the hopper stands out as a crucial part in charge of reliably holding and distributing the dough mixture. Hoppers are specifically made to hold large amounts of dough and are frequently fitted with cutting-edge precision technology to ensure precise portion control. Due to the careful attention to detail, the biscuits are guaranteed to remain the same size and form throughout the whole production process, allowing for even dough distribution.

The conveyor system is another key element. The dough must be moved from the hopper to the cutting and shaping processes using conveyors. They have belts or chains that transport the dough down the assembly line smoothly and effectively. Different biscuit patterns may be accommodated because of the conveyor system's adjustable speed and flexibility in shaping and cutting the dough. Additionally, sensors and monitoring tools are frequently incorporated into conveyors to maintain constant dough flow and identify any anomalies or obstructions that can stop the production process.

The baking oven is also a crucial part of the equipment used to make biscuits. For thorough and reliable baking of the biscuits, these ovens are made to give exact temperature control and equal heat dispersion. They frequently include many zones, allowing for differing baking conditions for different kinds of biscuits. Depending on the particular needs of the biscuit production process, baking ovens can be set up with various types of heating devices, such as electric or gas. To get the correct texture, color, and crispiness of the biscuits, temperature, and timing restrictions are meticulously watched.

Factors to Consider When Choosing Biscuit Making Machinery

Numerous important elements should be taken into account when choosing biscuit-making machines to make sure the best option is made for your particular production requirements. First and foremost, production capacity is an important factor. It is critical to determine your intended output volume and select equipment that can satisfy or surpass it. It is important to consider elements like the hopper's size, the conveyor system's speed, and the oven's baking capacity. Maximizing efficiency and avoiding possible bottlenecks in the manufacturing process may both be accomplished by choosing machinery that is in line with your production needs.

Second, it is crucial to think about how adaptable and flexible the equipment is. The degree of customization and diversity of biscuit shapes, sizes, and textures available from various biscuit-making equipment varies. You could need equipment that enables simple setup and mold configuration adjustments depending on your target market and consumer preferences. To effectively fulfill market needs, it's critical to select machinery that can handle the needed biscuit variations.

When choosing biscuit-making equipment, dependability and durability should also be taken into consideration. Investing in durable, well-made equipment will help to reduce downtime from malfunctions or maintenance problems, assuring constant output and lowering the possibility of expensive disruptions. It is advised to select equipment from reputed producers recognized for their high caliber and dependability. To quickly resolve any potential difficulties, take into account the availability of spare parts and expert assistance.

FAQs: Biscuit Making Machinery

Q. What are some tips for operating and maintaining biscuit making machinery?

Ans: Paying close attention to the little things and following the rules is necessary while using and maintaining biscuit-making equipment. Here are some excellent pointers to guarantee efficient equipment operation and upkeep. The manufacturer's instructions and operation handbook must be carefully read and understood first. Get acquainted with the machinery's individual features, controls, and safety measures. To avoid needless wear and tear and to preserve the equipment's lifespan, adhere to the suggested operating methods, including start-up and shutdown sequences.

Implementing a regular cleaning and maintenance schedule is crucial for ensuring the best operation of biscuit-making equipment. Create a complete maintenance schedule that includes necessary chores like routine cleaning, lubrication, and component checks. By regularly cleaning the equipment, you may get rid of any accumulation or residue that can jeopardize hygiene requirements or affect performance. For efficient maintenance, follow the manufacturer's instructions and use the cleaning agents they propose. Prioritize the lubrication locations as well to make sure that all moving components get enough lubrication at the right times. Regularly check belts, gears, and other essential parts to see any wear or damage that requires emergency repairs.

Additionally, it is crucial to integrate routine equipment calibration and modification. This guarantees exact quantity control, uniform dough thickness, and ideal baking circumstances. It is essential to calibrate sensors, temperature controls, and timers in order to maintain precision and provide outstanding cookie quality. To track equipment performance and identify any recurrent problems, thorough records of all maintenance processes, including cleaning, lubrication, and calibration, must be kept. These precise records allow for extensive equipment evaluation, proactive troubleshooting, and prompt problem-solving.

Lastly, support operators and maintenance personnel with appropriate training. Make that they have received enough instruction about the maintenance, safety, and operation of the biscuit-making equipment. Refresher training or courses should be regularly offered to keep employees current on industry trends and best practices.

Q. How has technology advanced in the field of biscuit making machinery?

Ans: Technology has significantly improved biscuit manufacturing equipment, altering the manufacturing process and raising overall productivity and quality. The incorporation of automation and electronic controls is one noteworthy development. The advanced sensors, actuators, and programmable logic controllers (PLCs) included in today's biscuit manufacturing equipment allow for exact control of a variety of production parameters. By automating the mixing, shaping, and baking of biscuits, human error is reduced, and consistency in size, texture, and appearance is guaranteed.

User-friendly interfaces and touchscreen controls are other areas where technology has advanced significantly. Now, operators may obtain real-time production data, easily monitor and modify machine settings, and solve problems quickly. The user-friendly interfaces enable simple recipe modifications, enabling the creation of several biscuit variants without requiring a lot of downtime.

Manufacturers & Suppliers of Biscuit Making Machinery

Company Name | Member Since |

|---|---|

Shanghai Fude Machinery Manufacturing Co., Ltd. Shanghai, China | 13 Years |

Vsa Machines India Hyderabad, India | 13 Years |

Empire Bakery Machines Pvt.Ltd Ludhiana, India | 13 Years |

Uttam Machinery Kolkata, India | 11 Years |

Pritul Machines Muzaffarnagar, India | 9 Years |

Devanand Engineering Works Ahmedabad, India | 7 Years |

Ultra Worldwide Pvt. Ltd. Mumbai, India | 4 Years |

Zhengzhou Kingdoo Machinery Co., Ltd. Zhengzhou, China | 2 Years |

Eversmart Food Equipment Limited Foshan, China | 2 Years |

Popular Products