Blow Moulding Machines

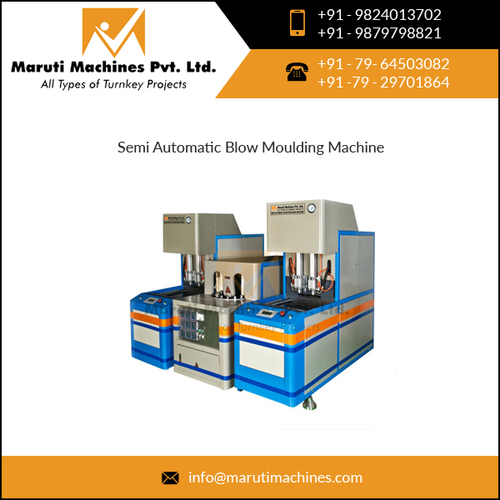

(1094 products)Semi Auto Blow Molding Machine - 2 Cavity, Output Up to 900 pcs/h | Robust Structure, Multiple Security Features, 380V, 50Hz

Price: 1000000 INR/Unit

MOQ01 Unit/Units

General UseIndustrial

ComputerizedNo

AutomaticNo

Voltage380 Volt (v)

Warranty1 Year`

White & Blue Water Bottle Blow Moulding Machine

Price: 900000.00 INR/Unit

MOQ1 Unit/Units

ColorWhite & Blue

Product TypeWater Bottle Blow Moulding Machine

TypeJuice Bottles, Carbonated Drink Bottles, Water Bottles, Oil Bottles, Cosmetic Bottles, Beverage Bottles

ComputerizedYes

AutomaticYes

Voltage440 Volt (v)

Automatic Plastic Extrusion Blow Moulding Machine

Price: 1000000 INR/Set

MOQ1 Set/Sets

ColorOther

MaterialStainless steel

FeatureHeavy Duty Machine, Durable, Rust Proof, Highly Efficient, Less Power Consumable, Other

ComputerizedYes

Automatic GradeAutomatic

Control SystemPLC Control

Labh Projects Pvt. Ltd.

Ahmedabad

Super Seller

Super Seller4 Years

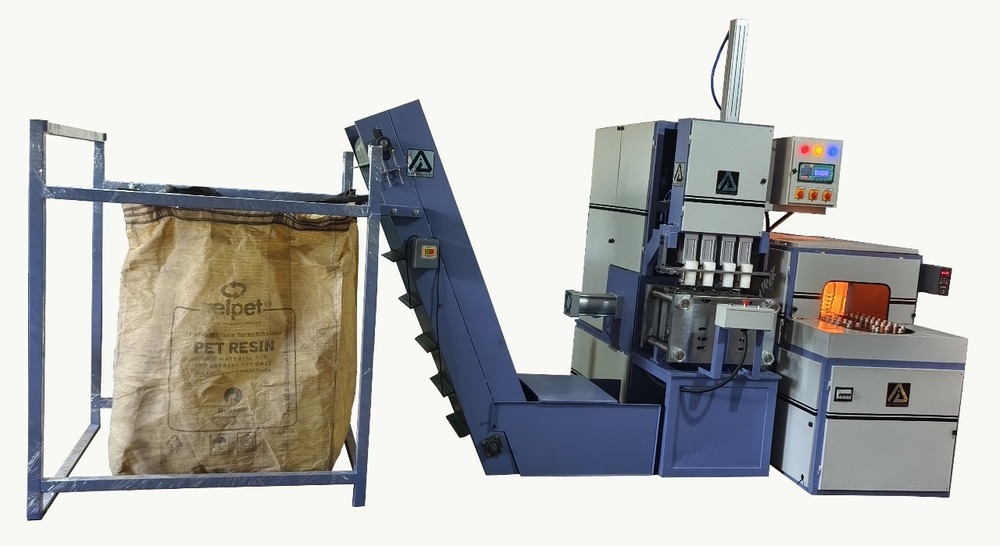

Fully Automatic Pet Blow Moulding Machine Capacity: 1000/2000/4000/6000/8500 Bph T/Hr

Price: 1490000 INR/Unit

MOQ1 , Unit/Units

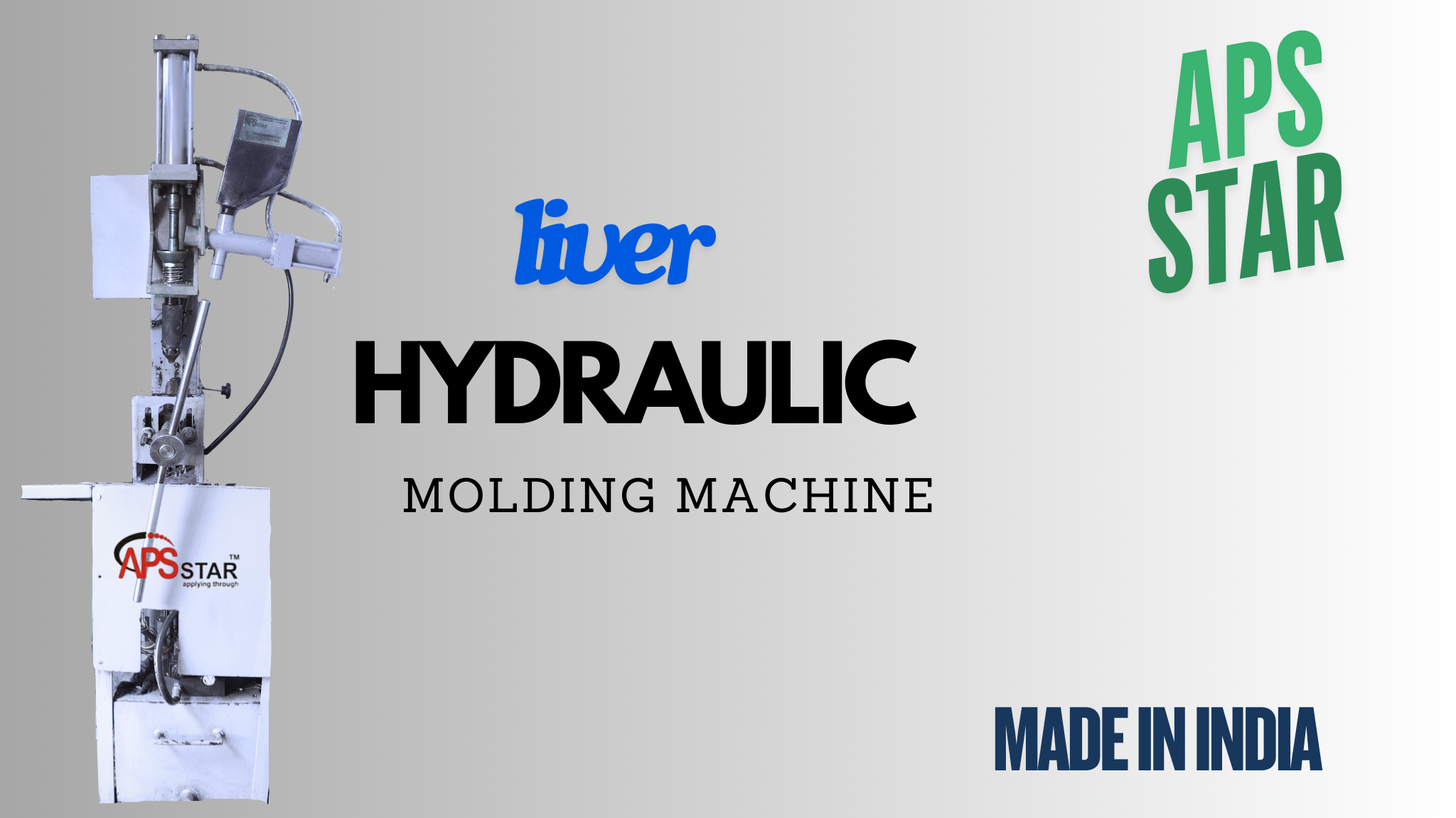

Product TypeHydraulic Clamping System

MaterialPET

Capacity1000/2000/4000/6000/8500 BPH T/hr

TypeWater Bottles, Beverage Bottles, Juice Bottles

ComputerizedNo

AutomaticYes

Excel Filtration Pvt. Ltd.

Ahmedabad

Blowing Machine - Heavy-Duty Plastic, 24x30 Inches , High Efficiency, Quiet Operation, Versatile Airflow Control

Price: 300000.00 INR/Piece

MOQ1 Piece/Pieces

Supply Ability2 Per Day

Delivery Time1 Week

Main Domestic MarketAll India

Hz-880 Semi-Automatic Stretch Blow Moulding Machine - Color: Silver

MOQ1 Unit/Units

MaterialOther, Metal

AutomaticYes

Voltage240 Volt (v)

ColorSilver

WarrantyYes

Bottle Blow Molding Machine - Mild Steel, Automatic Blue Design | Industrial Efficiency with Warranty

Price: 7,50,000 INR/Piece

MOQ1 Piece/Pieces

ColorBlue

Product TypeBottle Blow Molding Machine

General UseIndustrial

MaterialOther, Mild steel

TypeOther

ComputerizedNo

Silver Automatic Pet Blow Moulding Machine

Price: 5,50,000 INR/Unit

MOQ1 Unit/Units

Colorsilver

Product TypePet Moulding Machines

General Usemaking bottles

MaterialOther, galvanised steel

TypeCarbonated Drink Bottles, Water Bottles

ComputerizedNo

Dewpure Engineering Pvt. Ltd.

Kolkata

Pet Blowing Machine - Plastic Material, 150mm Power Stroke, Blue and Grey Color | 220 Volt, 1 Year Warranty, Two Cavity Pneumatic Valves

Price: 800000 INR/Unit

MOQ1 Number

ColorBlue and grey

Product Typeblowing machine

MaterialPlastic

ComputerizedNo

AutomaticNo

Voltage220 Volt (v)

Blow Moulding Machine - Continuous Hydraulic Clamping with AC Variable Speed Drive | Single & Multiple Heads, Compact Size, Low Operational Cost, Mass Production Capabilities, Complete PLC Control

Product DescriptionOur company is manufacturing, exporting and supplying a quality range of Blow Moulding Machine. These are continuous type machines with hydraulic clamping and shooting unit. Extruder output is controlled by AC Variable Speed Drives. The compact size of the machine is an advantage for the small units

High Transparency Fully Auto Bottle Blowing Machine

MOQ1 Unit/Units

Product TypeBottle Blowing Machine

General UseIndustrial

TypeJuice Bottles, Water Bottles

AutomaticYes

FeatureFull Automatic, High Transparency

Warranty1 Year

Automatic Blow Molding Machine - Heat Resistant, Colour Coated | Extrusion Blow Molding, Automatic Operation, Warranty Included

Price: 14,00,000 INR/Piece

MOQ1 Piece/Pieces

Colorcolour coated

Product TypeAutomatic Blow Molding Machine

General Usemaking bottles

ComputerizedNo

AutomaticYes

Blow Moulding TypeExtrusion Blow Moulding

Pet Bottle Blowing Machine - Automatic Operation, 1 Year Warranty | Industrial Use, Blue Design

Price: 700000 INR/Piece

MOQ1 Piece/Pieces

ColorBlue

Product TypePet Bottle Blowing Machine

General UseIndustrial

AutomaticYes

Warranty1 year

Purelife Filtration Private Limited

Mira Bhayandar

Semi Auto Blow Molding Pet Bottle Machine - Color: Blue

Price: 750000 INR/Unit

MOQ1 Unit/Units

ColorBLUE

Product Typemoulding machine

General UseIndustrial

MaterialPET

Capacity1000 Per Hour or As per bottle size Pcs/hr

Weight (kg)1180 KG Kilograms (kg)

Glycerin Soap Moulding Machine - Capacity: 200-500 Kg/Hr

Price: 200000 INR/Unit

MOQ1 Unit/Units

Capacity200-500 Kg/hr

Power220-440 Volt (v)

FeatureDurable

FunctionAutomatic

WarrantyYes

Blue-Grey 60 Bpm Pet Stretch Blow Moulding Machine

Price: 3500000 INR/Piece

MOQ1 Piece/Pieces

ColorBlue-Grey

Product Type60 BPM Pet Stretch Blow Moulding Machine

General UseIndustrial

MaterialPET

AutomaticYes

Blow Moulding TypeStretch Blow Moulding

Swadeshion Interchange & Chemicals Private Limited

Midnapore

Well Plug Meking Molding Machine - Feature: Full Automatic

Price: 700000 INR/Unit

MOQ1 Unit/Units

General UseIndustry

MaterialOther, Mild steel

ComputerizedNo

AutomaticYes

Voltage220-440 Volt (v)

FeatureFull Automatic

20 Ltr Jerry Can Blow Moulding Machine - Cavity Quantity: Single & Multiple Unit

Price: 1500000.00 INR/Unit

MOQ1 Unit/Units

Product TypeBlow Moulding Machine

General UseIndustrial

ComputerizedNo

AutomaticYes

Blow Moulding TypeExtrusion Blow Moulding

Cavity QuantitySingle & Multiple Unit

Sumitek Natraj Machinery Private Limited

Ahmedabad

3 Cavity Automatic Pet Blow Moulding Machine Industrial

Price: 951000 INR/Unit

MOQ1 Unit/Units

General UseIndustrial

ComputerizedNo

AutomaticYes

Blow Moulding TypeExtrusion Blow Moulding

WarrantyYes

Semi Automatic PET Blow Molding Machine - 1-5 Litre, 1100 BPH Production Capacity, White Color, 3 Phase Power, 2 Cavity Design, Warranty Included

Price: 590000 INR/Piece

MOQ1 Set/Sets,

ColorWhite

AutomaticYes

Power3 phase Volt (v)

WarrantyYes

Aluminium 2 Litre Jar Blowing Machine

Price Trend: 750000.00 - 750000.00 INR/Set

MOQ1 Set/Sets,

Molding MaterialAluminium

Cavity2 Cavity

Product Type2 Liter Jar Blowing Machine

General UseJar

MaterialPET

CapacityDepend on production Pcs/min

1 Ltr Semi Automatic Pet Blowing Machine - Color: Blue

Price: 700000 INR/Piece

MOQ1 Piece/Pieces

ColorBlue

Product Type1 Ltr Semi Automatic Pet Blowing Machine

General UseIndustrial

ComputerizedNo

AutomaticNo

Warranty1 Year

Pet Jar Blowing Machines

Price: 1500000 INR/Unit

MOQ10 Unit/Units, Unit/Units

Product DescriptionPet Jar Blowing Machines

Dharmanandan Techno Projects Pvt. Ltd.

Surat

Trusted Seller

Trusted Seller10 Years

Fully Auto Blow Moulding Machine

Price: 60000 INR/Pair

MOQ1 Pair/Pairs

FOB PortAhmedabad

Payment TermsLetter of Credit (L/C), Cash in Advance (CID), Cheque, Cash Advance (CA)

Supply Ability02 Per Week

Shiiv Shakti Water Equipment Private Limited

Ahmedabad

Industrial Blow Molding Machine

Price: 200000.0 INR/Unit

MOQ1 Unit/Units

TypeBlow Molding Machine

Evolution Technology

Bhiwandi

Trusted Seller

Trusted Seller2 Years

Fully Automatic PET Blow Moulding Machine - PET Material, 220-440 Volt, Blue and Silver | Warranty Included, Fully Automatic Operation

Price: 1670000 INR/Unit

MOQ1 Unit/Units

ColorBlue and Silver

Product TypeFully Automatic PET Blow Moulding Machine

MaterialPET

AutomaticYes

Voltage220-440 Volt (v)

WarrantyYes

Verma Process Pack

Delhi

Trusted Seller

Trusted Seller8 Years

Eco Water Solutions Technologies Pvt. Ltd.

New Delhi

Hdpe Blow Moulding Machine - Feature: High Transparency

Price: 2000000 INR/Unit

MOQ1 Unit/Units

General UseIndustrial

MaterialOther, SS

ComputerizedNo

AutomaticYes

Blow Moulding TypeExtrusion Blow Moulding

Voltage220 Volt (v)

Latest From Blow Moulding Machines

Plastic Blow Molding Machine

By:

Svas Hydropneumatic Engineers Llp

Extrusion Blow Moulding Machines

By:

Supreme Moulds & Machinery

Auto Deflashing Blow Moulding Machine

By:

Manjiree Engineering

Explore More Cities

Ready To Ship Blow Moulding Machines

What Are Blow Moulding Machines?

Blow moulding machines are pieces of industrial equipment used to blast plastic into moulds. Their principal goal is to manufacture a wide range of hollow plastic products such as bottles, jars, automotive components, consumer goods, healthcare items, and packaging materials. These machines vary in size, manufacturing capacity, and complexity, and are designed to satisfy the specific needs and applications of manufacturers.

The manufacturing process of these machines commences by melting plastic components, employing contemporary production techniques. Subsequently, the molten plastic is meticulously shaped and formed within a mold cavity, utilizing air pressure. This innovative technology allows for the production of hollow objects with precise dimensions and intricate details that surpass the rigorous quality standards set by various industries.

Blow moulding machines are of paramount importance in the industrial industry. This helps in allowing for the efficient and cost-effective production of a broad range of plastic items. Manufacturers may customise these machines to meet their individual manufacturing demands, assuring maximum performance and output.

Key Elements of Blow Moulding Machines

The blow molding machines encompass several key components that contribute to their efficient operation:

- Clamping Unit: This integral part of the machine securely holds the mold in place during the blow molding process, ensuring its stability and accuracy.

- Extruder: The machine features an extruder, serving as a vital component. It comprises a rotating screw that effectively melts the plastic material, creating a uniform molten mass ready for shaping.

- Control System: The included control system regulates and manages various machine functions. Equipped with an operator interface, it enables adjustments and settings for temperature, timing, and other parameters. This enhances the efficiency and smoothness of the blow molding process.

- Die Head: This component shapes the molten plastic into a parison, which is a hollow tube-like structure. The die head controls the size and final shape of the formed product through its specific size and configuration.

- Blow Pin and Mandrel: Both the blow pin and mandrel play a crucial role in achieving intricate and deep shapes for the final product, contributing to its desired form and dimensions.

- Cooling System: The cooling system aids in solidifying and cooling down the plastic material. It accomplishes this by circulating chilled air or water, efficiently removing heat from the plastic and facilitating its solidification.

Types of Blow Moulding Machines

- Injection Blow Moulding Machine – These machines are suited for small- to medium-sized production runs. Supplied machines are apt for the packaging industry for the production of containers and plastic bottles. These are accessible with functional advantages such as high precision, excellent surface finish, dependable wall thickness, etc.

- Pet Blowing Machine – These machines have been tailored to run into specific production supplies. Supplied machines are made to provide accommodations in various bottle sizes neck finishes and shapes. The machines allow for high flexibility and production versatility.

- High Transparency Fully Auto Bottle Blowing Machine- These blowing machines are demanded in the sectors of beverage, cosmetics, household products, pharmaceuticals, and others. The machines are crucial for high customer appeal and product branding.

- Industrial Pet Stretch Blow Molding Machine- This is an essential piece of equipment, suited for large-scale bottle production. It is an efficient and cost-effective solution.

- Extrusion Blow Molding Machine- This machine makes use of a process known as extrusion which can melt down the material of plastic.

- Accumulation Blow Molding Machine- The said machine is known well for producing industrial-sized and large products such as tanks, drums, and containers. The machine can make the plastic material very well.

Advantages of Blow Moulding Machines

Blow molding machines have brought about a revolution in the industrial sector, empowering companies to meet consumer demands for plastic products. The method of plastic production employed by these machines enables rapid manufacturing and high-volume outputs, ensuring efficient production processes.

One of the key advantages of blow molding machines is their versatility in producing a wide variety of plastic products. Engineers can explore innovative designs and manufacture diverse items, ranging from seat supports for vehicles and fuel tanks to toy wheels and flower pots, catering to various industries and consumer needs.

Blowing moulding machines speed up the production process by combining extrusion blow moulding. Furthermore, they may create external threads, which results in lower staff costs and higher total production.

Blow moulding equipment employs advanced techniques that streamline a multitude of end product production processes. These fully automated devices not only enhance manufacturing procedures but also ensure unwavering and dependable output.

Blow moulding machines yield a significant surge in production, empowering manufacturers to generate larger volumes within shorter timeframes. The ability to accommodate 3D mouldings facilitates seamless and expeditious manufacturing cycles, thereby bolstering overall efficiency.

Additionally, blow moulding machines offer remarkable design versatility, enabling the consistent fabrication of customized items. Plastic goods can be produced in a myriad of forms, styles, and sizes, catering to specific requirements and appealing to a broad range of client preferences.

Industries that Use Blow Moulding Machines

- Automotive

- Medical

- Marine

- Construction Food and Beverage

- Consumer Goods Industry

- Industrial Containers

- Packagings

- Furniture

- Electronics

- Electrical & Electronics

FAQs: Blow Moulding Machines

Q. How does a blow molding machine work?

Ans: The blow molding machines facilitate a process wherein a plastic tube is heated to its melting point, and subsequently, compressed air is employed to inflate the molten plastic. The quality of the final products heavily relies on the choice of plastic and air pressure utilized. The machine operates through a series of meticulously orchestrated steps:

- Extrusion: The machine carefully melts the plastic material, resulting in the formation of a homogenous molten plastic mass.

- Parison formation: The molten plastic undergoes extrusion via a precisely designed die head, shaping it into a tube-like structure referred to as a parison. This parison is then securely clamped vertically between two meticulously crafted halves of a mold.

- Mold closing: The mold promptly closes to create a meticulously sealed cavity that impeccably matches the desired shape.

- Blow molding, cooling, and ejection: With the introduction of compressed air, the parison expands, perfectly conforming to the intricate contours of the mold cavity. As the plastic cools, it solidifies, flawlessly adopting the precise shape of the mold. Finally, the machine skillfully ejects the impeccably formed finished product.

- The blow molding process executed by these machines delivers exceptional versatility and efficiency, catering to the production of an extensive array of hollow plastic products.

Q. How often should blow molding machines be maintained?

Ans: Operating a blow molding machine requires a comprehensive understanding of its mechanics and functions. Operators must possess a thorough knowledge of the screw's characteristics to effectively control the heating and cooling procedures. The machine's design, assembly, and features are intentionally crafted to streamline and optimize the extrusion process, leading to enhanced efficiency.

Regular inspection of the runners and mold cavities is imperative to eliminate any build-up of material residues. Ensuring proper maintenance of the machine is vital to prevent the occurrence of faulty components, thereby ensuring uninterrupted operation. It is recommended to conduct monthly assessments to detect any signs of rust and mitigate the risk of moisture-induced damage to the mold orifice.

Q. What factors should I consider when selecting a blow molding machine for my business?

Ans: Below here are some of the factors, which must be considered before choosing blow molding machines;

- Capacity: The production capacity of the blow molding machines is quite commendable. The machine's production capacity has a critical role in expanding the business. After they are selected, the machine should have 25 percent more capacity so as to develop the business regularly.

- Automation: The machines are included with many latest features as well as a high level of automation. The automation of the blow molding machine can save both money and time in business. Make sure that the relay logic or a PLC control is incorporated in the model of the machine you are going to buy as these features make the product smooth. In addition, these enable the manufacturers to display different operations of a machine. Manufacturers can easily understand the type of automation required for their flourishing business.

- Demo: The machine’s demonstration will help you to choose from several blow molding machines. The well-known manufacturers can find the demo of the blow molding machines online as well as at the manufacturing facility. It will help them to see the production process and how the machine works. The representative of the company will explain the mechanism and functional steps of the machine with the help of the Internet. Customers must look for the best business suggestions before they spend a high amount of money on these industrial machines. They must choose a machine that can make plastic products of excellent electrical insulating properties, high impact strength, low-temperature toughness, high resistance to chemicals, etc.

Q. What is the life of a molding machine?

Ans: Blow molding machines generally have a maximum lifetime of 500,000 cycles, which is considered the industry standard. The actual longevity, however, may vary depending on factors such as the precise kind and brand of the moulding machine. Depending on their design, structure, and components, different machines may have different durability and lifetime.

To guarantee maximum performance and lifetime of blow molding equipment, producers and operators must follow industry standards and recommendations.

Manufacturers & Suppliers of Blow Moulding Machines

Company Name | Member Since |

|---|---|

Hydro Power Engineering System Bengaluru, India | 20 Years |

Eco Water Solutions Technologies Pvt. Ltd. New Delhi, India | 19 Years |

Pharma Packaging Technology Thane, India | 15 Years |

Maruti Machines Pvt. Ltd. Ahmedabad, India | 13 Years |

Madhusudan Aqua Industries Vasai, India | 11 Years |

Shiiv Shakti Water Equipment Private Limited Ahmedabad, India | 11 Years |

Ocean Techno Ahmedabad, India | 10 Years |

Dharmanandan Techno Projects Pvt. Ltd. Surat, India | 10 Years |

Excel Filtration Pvt. Ltd. Ahmedabad, India | 9 Years |

Mech Tech Industries Howrah, India | 8 Years |

Popular Products