Box Making Machines

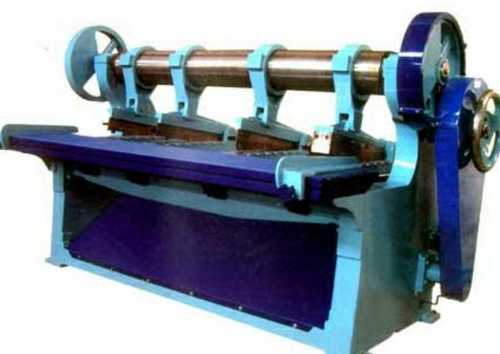

(818 products)BOXMAC Double Profile Fingerless Corrugation machine bearing mounted at High speed

Price: 1815000 INR/Set

MOQ2 Set/Sets

Product TypePaper corrugation machine

MaterialCardboard

Weight (kg)6700 Kilograms (kg)

TypeCorrugated Box Making Machine

ComputerizedYes

AutomaticNo

Senior Paper Packing Machinery Mfg. Co.

Amritsar

Automatic Fruit Rigid Carton Box Making Machine - Color: Silver

Price: 3000 USD ($)/Unit

MOQ1 Unit/Units

Product TypeAutomatic Fruit Rigid Carton Box Making Machine

Weight (kg)600kg Kilograms (kg)

ComputerizedYes

AutomaticYes

Drive TypeElectric

Power380V/50Hz, 4.5kw Volt (v)

Ruian Good Machinery Co. Ltd

Wenzhou

Durable Overhung Eccentric Slotter

Product DescriptionWe are offering our customers a wide range of Overhung Eccentric Slotter. The next process after cutting and creasing of the sheet is slotting and corner cutting. It is simultaneously carried over this machine. Three slotting and one corner cutting die can be easily adjusted by gear rack mechanism

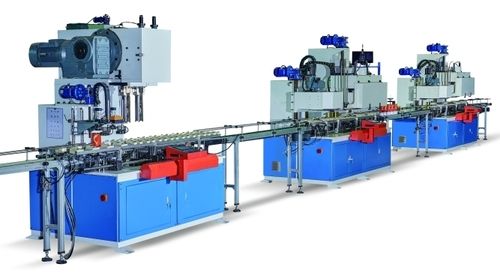

Blue 5L Rectangular Can Making Line

Price: 10000 INR/Piece

MOQ100 , Piece/Pieces

ColorBlue, Grey and Red

Product Type5L Rectangular Can Making Line

General UseCan Making

AutomaticYes

White-Yellow-Red Box Forming Machine

Price: 150000 INR/Piece

MOQ1 Piece/Pieces

ColorWhite-Yellow-Red

Product TypeBox Forming Machine

General UseIndustrial

TypeCorrugated Box Making Machine

FunctionHigh Functionality

AutomaticYes

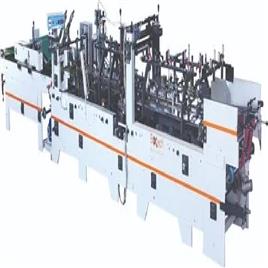

Box Carton Folding Gluer Machine In Bengaluru Boxtech Bangalore, Surface Finishing: na

Product DescriptionBox Carton Folding Gluer Machine In Bengaluru Boxtech Bangalore

Js-01 Cre Carton Creator Machine Dimension (L*W*H): 330-530 Mm (L) - 165-330Mm (W)Machine Millimeter (Mm)

Price: 1050000 INR/Unit

MOQ1 Unit/Units

Product TypeCarton Creator Machine

Weight (kg)400 Kilograms (kg)

ComputerizedNo

AutomaticYes

Drive TypeElectric

Dimension (L*W*H)330-530 mm (L) - 165-330mm (W)Machine Millimeter (mm)

J Pack Engineers Private Limited

Ahmedabad

Premium Seller

Premium Seller1 Years

Brown Corrugated Sheet Pressing Machine

Price Trend: 150000.00 - 250000.00 INR/Unit

MOQ1 Unit/Units

Product TypeCorrugated Sheet Pressing Machine

General UseIndustrial

Weight (kg)800-1800 Kilograms (kg)

TypeCorrugated Box Making Machine

ComputerizedNo

AutomaticYes

Tin Can Making Machine - General Use: Industrial

Price: 240000.0 INR/Unit

MOQ10 Unit/Units

General UseIndustrial

ComputerizedNo

AutomaticYes

Drive TypeElectric

MS Single Facer Corrugated Line - Electric Drive, 380 Volt | Automatic Industrial Machine with Warranty, Low-Maintenance Design

MOQ1 Unit/Units

Product TypeMS Single Facer Corrugated Line

General UseIndustrial

AutomaticYes

Drive TypeElectric

Voltage380 Volt (v)

WarrantyYes

Blue & Gray 5 Ply Fully Automatic Corrugated Board Production Line

Price Trend: 16000000.00 - 22500000.00 INR/Unit

MOQ1 Unit/Units

Product Type5 Ply Fully Automatic Corrugated Board Production Line

General UseIndustrial

MaterialPlywood

TypeCorrugated Box Making Machine

ComputerizedNo

AutomaticYes

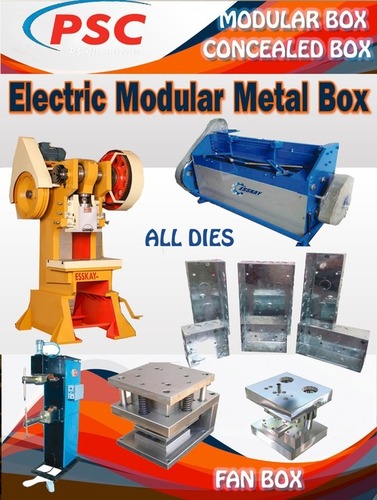

Fan Box Making Machine

Price Trend: 100000.00 - 1000000.00 INR/Piece

MOQ1 Piece/Pieces

Supply Ability5 Per Week

Delivery Time20 Days

Corrugated Box Making Machine Dimension(L*W*H): 7000-1300(1500)(1600)-1300Mm Millimeter (Mm)

Price: 3000000 INR/Unit

MOQ1 Unit/Units

Product TypeCorrugated Box Making Machine

General UseIndustrial

Weight (kg)2200KG Kilograms (kg)

ComputerizedNo

AutomaticYes

Drive TypeElectric

Prosper Choice Import Export

Greater Noida

Trusted Seller

Trusted Seller5 Years

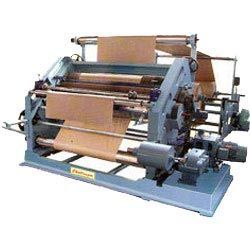

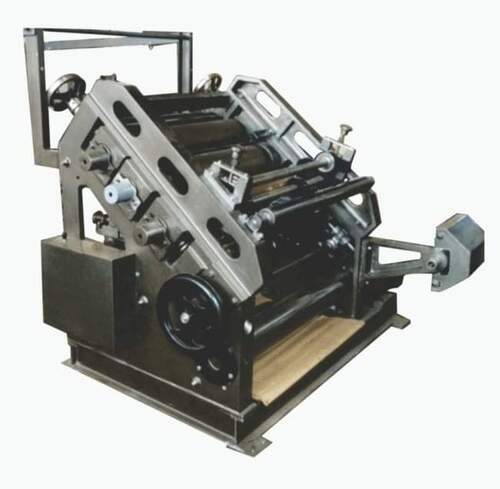

Dynamic Balancing Flexographic Printing Cum Sheeting Machine

Price Trend: 795000.00 - 775000.00 INR/Unit

MOQ1 Unit/Units

Product TypeFlexographic Printing Cum Sheeting Machine

General UseIndustrial

AutomaticYes

Drive TypeElectric

FeatureDynamic Balancing

Warranty1 Year

Semi-Automatic Fully Automatic Layer Plant

Price: 16000000 INR/Unit

MOQ1 Unit/Units

ColorSilver

Product TypeAutomatic Layer Plant

General UseIndustrial

MaterialOther, SS

Automatic GradeSemi-Automatic

ComputerizedNo

Electrical Pvc Junction Box Making Machines - General Use: Industry

Price: 720000 INR/Unit

MOQ1 Unit/Units

General UseIndustry

MaterialOther, Mild steel

FunctionAutomatic

AutomaticYes

Drive TypeElectric

Voltage220-440 Volt (v)

Bearing Mouted Oblique Type Corrugation Machine

Price: 1,150,000 INR/Piece

MOQ1 Piece/Pieces

Product DescriptionA premium quality Bearing Mouted Oblique Type Corrugation Machines, which are aesthetically designed and made by industrial experts keeping in view the various needs of the clients, are being offered to all our clients. These Machines are highly demanded for their higher functionality and durable wo

Natraj Box Making Machine

Product DescriptionWe have emerged as the foremost Exporter, Importer, Manufacturer, Distributor, Supplier, Trading Company of Natraj Box Making Machine in Delhi, India. This machine is widely used for the making of a corrugated box. To ensure its sturdiness at our clients' end, our quality examiners stringently check

Box Mania Pvt. Ltd.

Sonipat

Premium Seller

Premium Seller9 Years

Manual Corrugated Carton Box Pasting Machine - Feature: Automatic Feeder

Price: 650000 INR/Unit

MOQ1 Unit/Units

General UseIndustrial

ComputerizedNo

AutomaticYes

Drive TypeElectric

Power200-240 Volt (v)

FeatureAutomatic Feeder

Blue Automatic Double Profile Corrugation Machine

Price: 1600000 INR/Unit

MOQ1 Unit/Units

ColorBlue

Product TypeDouble Profile Corrugation Machine

General UseIndustrial

TypeBox Stitching Machine

ComputerizedNo

AutomaticYes

Supercut Engineers Private Limited

Mumbai

Electric Eccentric Slotter Machine - Metal Construction, 65 Inch Size, 12 Inch Maximum Slot Depth | Dark Blue, 2 HP Automatic, 220 Volt Power

MOQ1 Unit/Units

Product TypeEccentric Slotter Machine

MaterialMetal, Other

ComputerizedNo

AutomaticYes

Drive TypeElectric

Voltage220 Volt (v)

Sun-up (india ) Paper Board Machinery (p) Ltd.

Bhiwandi

Erected Box Carton Pasting Machine -BFM -4000

Price: 1800000 INR/Unit

MOQ1 Unit/Units

Product Typefood packaging box type machine

General Useuse for different type of trays/lunch boxes ,burger boxes

MaterialPaper

Capacity70-180 Pcs/min

Weight (kg)150-1000 Gram (g)

Functionuse for different types of trays/ lunch boxes burger boxes etc

Agarwal Trafin Private Limited

Kolkata

High Speed Corrugation Machine (Vertical Type / Oblique Type)

Payment TermsOthers, Cash in Advance (CID), Cheque, Cash Advance (CA)

Sample PolicyContact us for information regarding our sample policy

Main Domestic MarketAll India

3 Ply Automatic Corrugated Box Making Machine - 3 Phase, 220-380 V, 50-60 Hz | Automatic Circulation, Automatic Feeder, Industrial Use, White Color, Warranty Included

Price: 13000000 INR/Unit

MOQ1 Unit/Units

ColorWhite

Product TypeAutomatic Corrugated Box Making Machine

General UseIndustrial

ComputerizedNo

AutomaticYes

FeatureAutomatic Circulation, Automatic Feeder

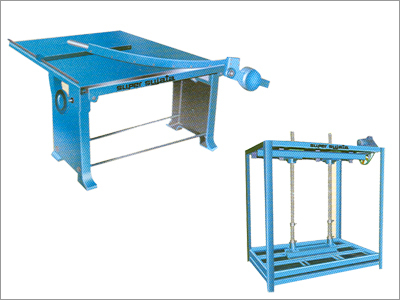

Board Cutter And Sheet Pressing Machine - Electric Drive, Blue Finish | 1-Year Warranty, Industrial Use

Price: 124500 INR/Unit

MOQ1 Unit/Units

ColorBlue

Product TypeSheet Pressing machine

General UseIndustrial

ComputerizedNo

AutomaticNo

Drive TypeElectric

Associated Industrial Corporation

Amritsar

Semi Automatic Corrugated Box Making Machine - Metallic Finish, User-Friendly, Prolonged Service Life | Smooth Functioning, Timely Delivery, Quality Tested

Product TypeCorrugated Box Making Machine

General UseTo make corrugated box

AutomaticYes

ColorMetallic

Automatic 5Ply Corrugated Board Making Plant - Feature: Plc Controll

Price: 19000000 INR/Unit

MOQ1 Unit/Units

Product TypeAutomatic 5ply Corrugated Board Making Plant

General UseIndustrial

ComputerizedNo

AutomaticYes

FeaturePLC Controll

Warranty1 year

Sukhmani Industries

Vasai

Trusted Seller

Trusted Seller3 Years

Latest From Box Making Machines

Corrugated Box Making Machines

By:

M. S. Machine Tools

Mild Steel Corrugated Box Making Machines

By:

Janta Printing & Packaging Machines

Carton Box Making Machines

By:

Ravi Engineering Works

Oblique Corrugation Box Making Plant

By:

Acme Machinery (india) Pvt. Ltd.

Corrugated Box Making Machine

By:

Naval (doaba) Industry

Corrugated Box Making Machine

By:

Bms Machine Tools

Explore More Cities

Ready To Ship Box Making Machines

Box Making Machines - Introduction

The packaging sector is undergoing a transformation because of the increased capabilities and productive manufacturing methods of box-making machines. These clever devices are made to make the process of producing boxes more efficient, allowing companies to easily produce customized boxes in a range of forms, sizes, and styles. Box manufacturing machines have evolved into an essential tool for businesses looking to improve their packaging processes because of their user-friendly interfaces and cutting-edge technology. Every step in the construction of a box may be automated with these machines, from cutting and creasing the cardboard sheets to folding and adhering them together, resulting in consistently excellent outcomes. Box-building machines provide unequaled versatility and speed, enabling firms to easily fulfill the demands of a dynamic market, whether it be for shipping, retail packaging, or product display. They are an environmentally beneficial option since their accuracy and precision in box creation not only save time but also reduce material waste. Box manufacturing machines are driving efficiency and innovation in the packaging sector by handling high volumes and accommodating a variety of customization choices. This enables firms to package their products safely and attractively while lowering costs and boosting productivity.

Various Kinds of Box Making Machines

When it comes to box-making machines, the packaging industry has a wide range of options to meet the various demands of the sector. These versatile machines provide a variety of settings and configurations specialized to certain applications, providing top-notch results. The corrugated box-making machine, which specializes in producing strong, long-lasting boxes from corrugated cardboard, is one of the frequently used varieties. These machines efficiently cut, crease, and fold corrugated sheets with maximum efficiency, producing robust boxes perfect for secure shipment and easy travel.

There are several different box-making machines available in the industrial industry, each with certain advantages. Consider the rigid box production machine, a perfect option for producing stunning, premium boxes that are frequently seen in the world of luxury packaging. This equipment ensures faultless presentation and the highest level of protection for pricey objects because of its accurate cutting, gluing, and wrapping capabilities. Conversely, folding carton box production equipment specializes in creating small, robust boxes that are frequently used in retail packaging. These amazing machines quickly change flat carton sheets into completely functional boxes by skillfully folding and sealing them. It is important to note that the sector also has specialist equipment made for particular box kinds.

Key Features of Box Making Machines

The multitude of essential functions that box-building machines are outfitted with make them crucial equipment for the packaging sector. One standout quality is their adaptability, which enables companies to make unique boxes in a range of forms, sizes, and styles to meet their particular requirements. These devices enable flexibility in modifying box dimensions, folds, and closures, guaranteeing that each created box satisfies exact specifications. Box-making equipment is also renowned for its effectiveness and rapidity. These machines can quickly make a large number of boxes using automated procedures including cutting, creasing, folding, and gluing, simplifying production, and fulfilling deadlines.

Their accuracy and precision are another outstanding quality. These machines regularly produce boxes with remarkable quality because to their accurate cuts, flawless creases, and seamless folds. Additionally, box-making equipment frequently has user-friendly user interfaces that make them usable by operators of all skill levels. These devices are simple to use, which lowers the learning curve and boosts productivity. They include straightforward controls and clear instructions. In order to ensure peak performance and save downtime, many box-making machines also provide features like automated adjustments, mistake detection systems, and real-time monitoring.

Top Industries That Use Box Making Machines

Machines that make boxes are extremely important in many different industrial businesses. These machines are widely used in many different industries, each with special needs and specifications. The packaging sector is among the most reliant on box manufacturing equipment. Packaging is essential for displaying and safeguarding products, whether they are food items, consumer goods, or industrial equipment. Packaging businesses can easily make a variety of boxes thanks to box-making machinery. Another significant business that extensively depends on box-making machinery is the e-commerce sector. Box-making machines expedite the manufacturing process, enabling e-commerce businesses to successfully satisfy the packaging demands of their clients. Furthermore, box building is often used in the pharmaceutical business.

Box-making machines also considerably aid the industrial sector as a whole. Boxes are a crucial component of manufacturing processes, whether they are used to convey finished goods or organize components throughout the production process. Box-making equipment gives producers the freedom to produce boxes in a range of shapes and sizes to suit their particular needs.

FAQs: Box Making Machine

Q. What is the avg. cost of box making machine?

Ans. A box-making machine's average cost might change based on a number of variables. These variables include the kind and degree of complexity of the machine, the quantity it can produce, the degree of automation, and the particular features and functions it provides. Box-making equipment typically costs between a few thousand and several hundred thousand dollars. Larger, high-capacity machines with significant automation capabilities attract a higher price tag whereas simpler, more economical machines are often geared for lower production quantities. Due to their superior technology and accuracy, specialty box-making equipment made for generating complicated and customized packaging solutions may also be more expensive.

Q. Can box making machines produce boxes of different sizes?

Ans. To meet the numerous packaging requirements across many sectors, box manufacturing machinery is made to make boxes in a variety of sizes. These devices are adaptable and customizable, enabling the manufacturing of boxes in a variety of sizes. The box-building equipment may be configured to produce small boxes for delicate items or big boxes for bulkier goods. Based on their unique needs, manufacturers are allowed to choose the preferred length, width, and height criteria. This versatility proves to be especially beneficial for businesses that deal with a variety of products or have to meet various packaging requirements.

Q. Are box making machines suitable for small-scale businesses?

Ans. Box-making machinery may or may not be a good choice for a small firm, depending on its particular requirements and environmental factors. Although large-scale manufacturing operations are frequently linked with box-making equipment, there are alternate options that are acceptable for smaller businesses as well. These machines provide several benefits for small businesses in terms of production, cost, and customizability. If a small firm uses boxes regularly and wants more control over its packing procedures, investing in a dependable box-making machine might prove to be a wise choice. It is crucial to take unique requirements, financial limits, and growth objectives into account while choosing the machine that best fits the company's goals and resources.

Q. What are the advantages of using a box making machine over manual box making methods?

Ans. Compared to manual box-making techniques, using a box-making machine has a number of benefits. First, higher production and efficiency are two of the major benefits. The whole box production process, from material cutting and scoring to folding and gluing, is automated by box-building machines. Due to the huge time and labor savings from this automation, more boxes can be produced in less time, increasing production volumes. Box-making machines expedite the whole process in comparison to manual techniques that rely on hand-cutting, measuring, and assembling, allowing firms to better satisfy client needs.

Second, box-making machinery guarantees accuracy and uniformity in box creation. Box dimensions may vary as a result of manual procedures, resulting in inconsistent packaging. But with the exact and consistent cuts, folds, and glue that box manufacturing machines offer, the boxes are standardized and appear professional. This uniformity not only improves the packaging's overall looks but also makes ensuring that the boxes are the right size to accommodate the goods, lowering the danger of damage during transit.

Additionally, adopting box-making machines might result in long-term cost reductions. Although a machine may need a larger initial investment than human techniques, the automation and efficiency of the equipment ultimately result in lower labor expenses. Businesses must commit people for each stage of the manual box-making process, raising labor costs. Box-making equipment, on the other hand, requires little operator involvement, enabling organizations to maximize their staff and devote resources to other crucial activities.

Finally, box-making equipment allows for versatility and personalization. To meet unique packaging needs, these machines may be programmed to produce boxes in a variety of sizes, shapes, and patterns. Manual techniques might not offer the same degree of personalization and might have fewer design alternatives. Box-making equipment enables companies to provide distinctive and branded packaging options, improving product presentation and customer satisfaction.

Manufacturers & Suppliers of Box Making Machines

Company Name | Member Since |

|---|---|

Monu Graphics Faridabad, India | 21 Years |

Associated Industrial Corporation Amritsar, India | 21 Years |

Senior Paper Packing Machinery Mfg. Co. Amritsar, India | 20 Years |

S. K. Package Machine Vapi, India | 17 Years |

Boxtech Bangalore Bengaluru, India | 16 Years |

Intimate Machine Tools Rajkot, India | 15 Years |

Balajee Machine Tools Bahadurgarh, India | 12 Years |

J V Machine Tools Private Limited Alwar, India | 11 Years |

Micro Engineers (India) Vasai, India | 10 Years |

P. S. Chemicals Indore, India | 9 Years |

Popular Products