Braiding Machine

(171 products)Fishing Net Braiding Machine Kbl16-4-120 Industrial

Price: 4600 USD ($)/Set

MOQ1 Set/Sets

Product TypeFishing Net Braiding Machine

General UseIndustrial

MaterialOther, SS

ComputerizedNo

AutomaticYes

Warranty1 Year

Taizhou Winstrong Special Net Co., Ltd.

Taizhou

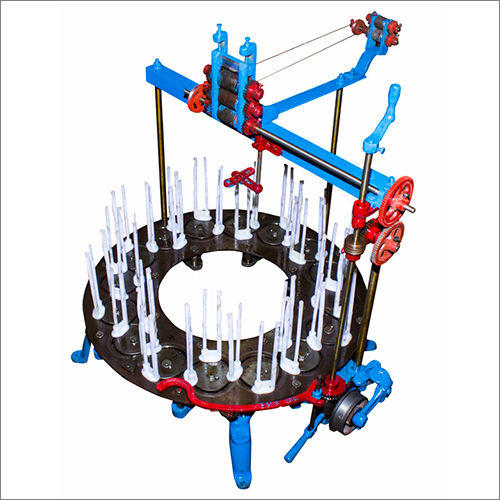

3 Ply Twisting Machine

Price Trend: 10000.00 - 15000.00 INR/Unit

MOQ1 Unit/Units

Supply Ability100 Per Month

Delivery Time1 Week

Main Export Market(s)Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

Srichand Engineering & Moulding Co.

Ahmedabad

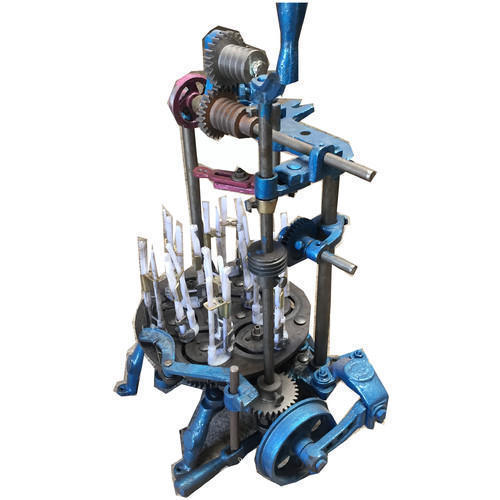

High Speed Copper Braiding Machine Bobbin Size: 75X22X70

Price Trend: 1000000.00 - 1300000.00 INR/Unit

MOQ1 , Unit/Units

Product TypeHigh Speed Copper Braiding Machine

General UseIndustrial Use

MaterialOther

Weight (kg)1258 Kilograms (kg)

TypeCable Braiding Machine, Wire Braiding Machine

PanelYes

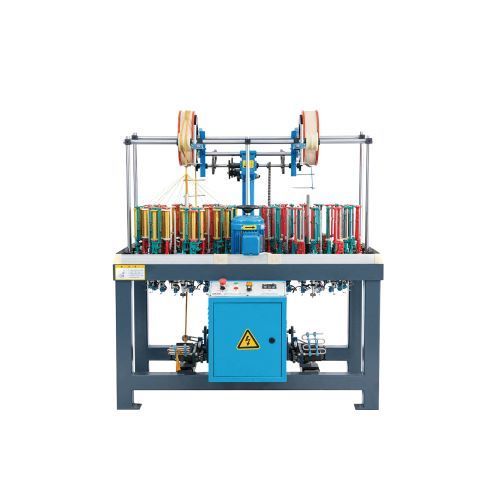

High Speed Braiding Machine 32-2-90

Price: 300000 INR/Piece

MOQ1 Piece/Pieces

TypeLace Braiding Machine, Shoelace Braiding Machine

PanelYes

FeatureHigh Speed

1-48 High Speed Braiding Machine

Price Trend: 30000.00 - 300000.00 INR/Piece

MOQ1 Piece/Pieces

Supply Ability1 Per Day

Delivery Time7 Days

90-16-4 High Speed Braiding Machine

Product Description90-16-4 High Speed Braiding Machine

Texzium International Pvt Ltd

Delhi

Braiding Machine Bobbin Size: 142Mm

Price: 270000 INR/Piece

MOQ1 Piece/Pieces

ColorBlue

Product TypeRope

MaterialPolyester

Weight (kg)600 Kilograms (kg)

TypeRope Braiding Machine, Lace Braiding Machine, Wire Braiding Machine, Cable Braiding Machine, Shoelace Braiding Machine

PanelYes

Jayson Engineering & Mfg. Co.

Ahmedabad

Lpg Rubber Hose Braiding Machine - Feature: Automatic Power Cut

Price: 125000 INR/Unit

MOQ1 , Unit/Units

Product TypeHOSE BRAIDING MACHINE

MaterialStainless Steel Wire

Weight (kg)450-500 Kilograms (kg)

ComputerizedNo

AutomaticYes

Voltage220 Volt (v)

Semi-Automatic High Speed Round Braiding Machine - Mild Steel, 240V | High Precision, Video Technical Support, Low Maintenance Cost, Easy to Operate, Ideal for Textile Industries

Price Trend: 95000.00 - 350000.00 INR/Piece

MOQ1 Piece/Pieces

Product TypeBraiding Machine

General UseIndustrial, Textile Industries

TypeRope Braiding Machine, Lace Braiding Machine

AutomaticYes

FeatureHigh Speed

Warranty1 Year

Lace Machine Lever

Product DescriptionUnder the assistance of our professionals, we are engaged in manufacturing and supplying a wide spread of Lace Machine Lever in Ballabgarh, Haryana, India. The offered Lace Machine Lever is made in-tandem with around the globe laid quality norms as these are created using best grade raw materials an

Semi-Automatic High Precision Electric Braiding Machine - Mild Steel, 240V, High Speed Control | Low Maintenance, Easy to Operate, Video Technical Support

Price Trend: 95000.00 - 350000.00 INR/Piece

MOQ1 Piece/Pieces

Product TypeBraiding Machine

General UseIndustrial, Textile Industries

TypeRope Braiding Machine, Lace Braiding Machine

FeatureHigh Speed

Warranty1 Year

Any Color High Performance Braiding Machine

Product DescriptionApplication:-\015\012Apply to produce low consumption, long life-span physical foam ploythyleneinsulation application fine coaxial cable, special wire cable, communication cable and data cable etc. Especially suitable for small coaxial cable production.\015\012\015\012Characteristics: Suitable to CA

Pinyang Machinery India Private Limited

Noida

High Speed 32 Spindle Rope Braiding Machine

Price: 500000 INR/Set

MOQ2 Set/Sets

General UseIndustrial

MaterialStainless Steel Wire

ComputerizedNo

AutomaticYes

FeatureHigh Speed

5 Spindle Extra Heavy Oil Bath Style Rope Braiding Machine Bobbin Size: 100 X 300

Price: 525000 INR/Piece

MOQ1 Piece/Pieces

ColorGreen

Product Type5 Spindle Extra Heavy Braiding Machine

General UseRugs, Durries

MaterialYarn Thread

Capacity60-90 Kg/day

Weight (kg)700 Kilograms (kg)

Bhupendra & Brothers (machinery) Pvt. Ltd.

Ahmedabad

Rope Braided Making Machine

Price: 5000 INR/Unit

MOQ4 Unit/Units

Product TypeRope Braided Making Machine

General UseIndustrial use

MaterialOther, Metal

PanelYes

ComputerizedNo

AutomaticYes

Zhangjiagang Brilliant Technology Co.,ltd

Suzhou

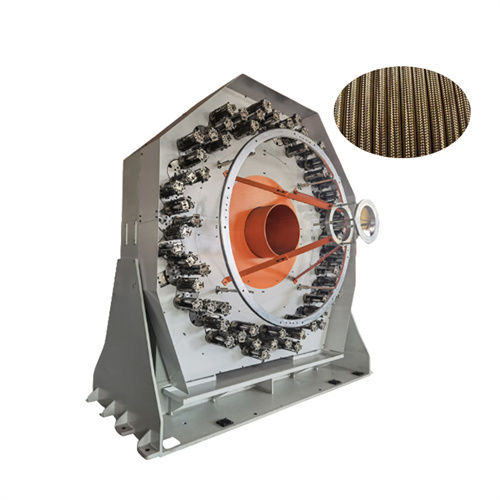

GBG-96 Wire Braiding Machine

Price: 5000 USD ($)/Pallet

MOQ1 Pallet/Pallets

FOB Portshanghai/Tianjin/Dalian

Payment TermsLetter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Western Union, Cash in Advance (CID), Cash Advance (CA)

Supply Ability300sets Per Year

Floor Mounted High Efficiency Electrical Braided Rope Machine - Metal, Customized Size, Color Coated, High Strength, Shock and Corrosion Resistant, Manual Control, High Speed, Humanization Design

Price: 160000 INR/Set

MOQ1 Unit/Units

Coloras Shown in The Image

Product TypeBraided Rope Machine

General UseIndustrial

MaterialOther, Metal

ComputerizedNo

AutomaticYes

Black 32 Spindle Rope Braiding Machine

Price: 14300 INR/Unit

MOQ10 Unit/Units

ColorBlack, Green

Product Type32 Spindle Rope Braiding Machine

FeatureHigh Speed

High Speed Hose Pipe Braiding Machine

Price: Approx Price: Rs 3.5 Lakh /Piece INR/Piece

MOQ1 Piece/Pieces

Product TypeBraiding Machine

General UseIndustrial Use

MaterialOther

PanelYes

Oil BathNo

ComputerizedNo

Semi-Automatic High Speed Round Braiding Machine - Mild Steel, 240V | High Precision, Low Maintenance, Easy Operation, Video Technical Support

Price Trend: 95000.00 - 350000.00 INR/Piece

MOQ1 Piece/Pieces

Product TypeBraiding Machine

General UseIndustrial, Textile Industries

TypeLace Braiding Machine, Rope Braiding Machine

AutomaticYes

FeatureHigh Speed

Warranty1 Year

Yarn Braiding Machine - Premium Quality Materials, Advanced Technology Integration, Durable Design

Product DescriptionWith passionate devotion and effort of our team of skilled professionals, we are involved in manufacturing, trading and supplying a supreme quality range of Yarn Braiding Machine in Delhi, Delhi, India. Our offered machines are precisely manufactured by making use of cutting edge technology. Our pro

Braiding Machines

Product DescriptionWe are a well-reputed firm that manufacture, export and supply an extensive range of Braiding Machines in Ahmedabad, Gujarat, India. Offered machine is manufactured by our professionals incorporating best in class raw material and most recent techniques to ensure its flawless range at user\342\200\

Semi-Automatic High Speed Round Braiding Machine - Mild Steel, High Precision, 240V | Low Maintenance, Easy Operation, Video Support

Price Trend: 95000.00 - 350000.00 INR/Piece

MOQ1 Piece/Pieces

Product TypeBraiding Machine

General UseIndustrial, Textile Industries

TypeRope Braiding Machine, Lace Braiding Machine

FeatureHigh Speed

Warranty1 Year

Semi-Automatic Lace and Rope Braiding Machine - High Precision, Mild Steel | 240V Electric Power Source, High Functionality, Easy Operation, Low Maintenance Cost, 1 Year Warranty, Video & Online Support

Price Trend: 95000.00 - 350000.00 INR/Piece

MOQ1 Piece/Pieces

Product TypeBraiding Machine

General UseIndustrial, Textile Industries

TypeLace Braiding Machine, Rope Braiding Machine

FeatureHigh Speed

Warranty1 Year

Rope Braiding Machine - SG Iron, Semi-Automatic, 100 Watt Power Consumption | Multi-Color, Computerized, Sharp Needle Knitting Style, 1-Year Warranty

Price: 2.7 INR/Piece

MOQ1 Piece/Pieces

Product TypeRope Braiding Machine

Weight (kg)Customized Kilograms (kg)

TypeRope Braiding Machine

Oil BathNo

ComputerizedYes

AutomaticYes

Semi-Automatic High Speed Round Braiding Machine - Mild Steel, 240V Electric Power | High Functionality, Easy Operation, Low Maintenance Cost, Precision Performance

Price Trend: 95000.00 - 350000.00 INR/Piece

MOQ1 Piece/Pieces

Product TypeBraiding Machine

General UseIndustrial, Textile Industries

TypeRope Braiding Machine

FeatureHigh Speed

Warranty1 Year

Blue Automatic Type Heavy Duty Braided Rope Machine

Price: 130000.00 INR/Piece

MOQ1 Piece/Pieces

ColorBlue

Product TypeHeavy Duty Braided Rope Machine

TypeRope Braiding Machine

ComputerizedNo

AutomaticYes

Semi-Automatic High-Speed Mild Steel Braiding Machine - 240V Electric Power Source, High Precision | Easy to Operate, Low Maintenance, Video Technical Support for Industrial Textile Use, 1-Year Warranty

Price Trend: 95000.00 - 350000.00 INR/Piece

MOQ1 Piece/Pieces

Product TypeBraiding Machine

General UseIndustrial, Textile Industries

TypeLace Braiding Machine, Rope Braiding Machine

FeatureHigh Speed

Warranty1 Year

Latest From Braiding Machine

90 164 High Speed Braiding Machine

By:

Texzium International Pvt Ltd

High Speed Braiding Machine 248A

By:

Susmatex Machinery

braiding machine

By:

V. D. Impex

Long Lasting And Durable Rust Proof Cast Iron High Speed Braiding Machine

50000 USD ($)

By:

Wuxi Longterm Machinery Technologies Co.,ltd.

Braiding Machine With Power Consumption : 1.5 Hp And Model Name/Number : Dhani E 4x16

300000 INR

By:

Jaldeep Enterprise

12 Spindle High Speed Braiding Machine

By:

Srichand Engineering & Moulding Co.

Ready To Ship Braiding Machine

Uses of Braiding Machines

Braiding machines, with their sophisticated machinery and exquisite architecture, have a wide range of applications in a variety of sectors. These technological wonders excel in the skill of interlacing fibers, wires, or even complicated patterns, demonstrating their adaptability and brilliance.

These machines revolutionize the manufacture of ropes, cords, and ornamental trimmings in the textile industry. Their ability to carefully interlace strands of diverse fabrics allows them to create long-lasting and visually beautiful goods, improving the quality and aesthetics of clothing, accessories, and home furnishings.

Braiding machines have also been used to reinforce and strengthen essential components in the automobile and aerospace sectors. These machines weave carbon fibers or other high-performance materials painstakingly, resulting in lightweight yet durable structures for use in vehicle chassis, aircraft wings, and even medical implants. The resultant braided construction is extremely strong.

Furthermore, braiding machines are essential in the fabrication of cables and wire harnesses in the field of electrical engineering.

To summarize, braiding machines are used in a wide range of industries and artistic endeavors. Their ability to interlace materials with precision and artistry has improved the quality, durability, and aesthetics of innumerable goods, demonstrating the influence of their creativity and adaptability.

Applications of Braiding Machines

Braiding machines, known for their sophisticated mechanics and accuracy, have a wide range of applications in a variety of sectors. These clever contraptions excel in interlacing fibers, wires, or elaborate patterns, presenting a plethora of functional and artistic options.

These machines revolutionize the manufacture of ropes, cords, and decorative trimmings in the textile industry. Their skill in precisely intertwining strands of various fabrics allows them to create durable and visually appealing goods, improving the quality and aesthetics of clothes, accessories, and home furnishings.

The automotive and aerospace industries have used braiding machines to strengthen and reinforce critical components. These machines weave carbon fibers or other high-performance materials, resulting in lightweight yet durable structures for use in automobile chassis, aircraft wings, and even medical implants.

Braiding machines have made advances in artistic and creative endeavors outside of industrial uses. Craftspeople use these machines to create elaborate braided patterns in fabrics, jewelry, and even furniture, imbuing their products with beauty and a sense of traditional workmanship.

Advantages of Using Braiding Machines

The use of braiding machines provides several benefits, emphasizing their importance and excellence in a variety of sectors. With their complicated mechanics and precise craftsmanship, these smart gadgets provide a slew of advantages that boost productivity, accuracy, and adaptability.

• Such machines are extremely efficient. Their automated operation speeds up the interlacing process, decreasing manufacturing time and increasing output.

• This kind of machine is quite precise. Their complex systems maintain continuous tension and alignment, resulting in perfectly woven patterns or structures. This accuracy is especially important in areas where tight adherence to requirements is required, such as aerospace or medical device manufacturing.

• Braiding machines provide unrivaled variety in addition to efficiency and accuracy. Their ability to interlace a vast range of materials enables the fabrication of goods with a variety of qualities.

• Another key benefit of these machines is their high strength and durability. These machines' interlacing approach results in constructions with increased tensile strength and durability.

• Furthermore, these machines help promote environmentally friendly production practices. They eliminate waste and optimize resource utilization due to the exact control they provide over material consumption.

Purchasing Guide for Braiding Machine

To make an informed selection when purchasing a braiding machine, it is vital to be armed with a detailed purchase guide. Several critical elements must be carefully considered to guarantee that the equipment chosen satisfies certain specifications and achieves the required results.

First and foremost, determining the intended application and manufacturing requirements are critical. Understanding the scope of the project, including the materials to be braided, desired pattern complexity, and projected production volume, sets the groundwork for selecting appropriate equipment.

Precision and adaptability are essential elements to consider. Machines with advanced features, such as adjustable tension control, pattern modification possibilities, and material compatibility, provide additional versatility and assure ideal outcomes.

The machine's dependability and durability are critical concerns. Examining the construction quality, manufacturer reputation, and accessibility of customer support and maintenance services is critical for ensuring long-term performance and minimizing downtime. Reading customer evaluations and obtaining advice from industry experts can give useful information regarding the machine's dependability and the manufacturer's track record.

Trends in Braiding Machine Industry

The braiding machine business is undergoing a surge of exciting changes that are transforming the landscape of this specialized industry. The integration of automation and digital technology is one major trend. Manufacturers are using innovative control systems and robots to improve braiding precision and efficiency. This integration not only lowers human error but also enables the creation of more sophisticated designs.

There is a noticeable trend towards a greater emphasis on sustainability and environmentally friendly practices in the braiding machine industry. Manufacturers are actively focusing on developing machines that minimize material waste, optimize resource usage, and incorporate eco-friendly materials and methods. This sustainability drive aligns with the broader global movement towards environmentally responsible production.

Furthermore, personalization and flexibility have emerged as crucial factors driving the braiding machine sector. Manufacturers are increasingly offering modular and adaptable equipment that can be easily customized to accommodate a wide range of braid sizes, patterns, and materials. This trend enables organizations to meet diverse customer expectations while remaining competitive in a rapidly evolving market.

They pave the way for the development of advanced, interconnected, and environmentally conscious braiding machines in the future, meeting the evolving needs of customers and aligning with sustainable manufacturing practices.

FAQs: Braiding Machine

Q. What are the different types of braiding machines available?

Ans. Circular Braiding Machines: These machines have a circular track or disc on which numerous carriers travel at the same time. They are widely used to make circular braids for applications like ropes, cords, and elastic bands.

Flat Braiding Machines: As the name implies, these machines generate flat or ribbon-like braids. They are used to make ornamental trimmings, shoelaces, and thin textiles and operate on a flat track or plate.

Overbraiding Machines: Overbraiding machines are used to provide a braided coating on cables, wires, or hoses. Multiple carriers travel in a circular or reciprocating motion to provide perfect interlacing of yarns or wires over a central core.

Lace Braiding Machines: Lace braiding machines are used to make elaborate and delicate braided lace designs. To generate complicated lace designs, these machines use a mix of circular and reciprocating carrier movements. They are frequently used in the manufacture of high-end fabrics, fashion accessories, and complex trimmings.

Rope Braiding Machines: Rope braiding machines are particularly developed for the production of strong and long-lasting ropes. Multiple carriers travel in a circular or reciprocating motion, interweaving different strands or fibres to form strong ropes. These machines are widely used in industries such as maritime, construction, and sports equipment production.

Q. What materials can be used with a braiding machine?

Ans. Braiding machines offer versatility in their support for a wide range of materials, enabling diverse applications and product possibilities. Some commonly utilized materials with braiding machines include:

Textile Fibers: Braiding machines can effectively weave natural fibers like cotton, wool, silk, as well as synthetic fibers such as polyester and nylon. These fibers find extensive use in the production of ropes, cords, belts, and decorative trimmings.

Wire and Cables: The wire and cable industry relies on braiding machines for manufacturing braided shields and reinforcement layers. Conductive metals like copper and aluminum are intricately braided to provide electrical conductivity, electromagnetic shielding, and mechanical strength.

Plastic and Rubber Materials: Braiding machines are adept at interlacing plastic and rubber materials, enabling the creation of braided hoses, tubes, and sleeves. These braided structures enhance flexibility, strength, and longevity, making them essential for fluid transfer, automotive systems, and industrial equipment.

Metal Wires: Braiding machines exhibit compatibility with various metal wires, including stainless steel, copper, and alloy wires.

Q. What are the advantages of using a braiding machine over manual braiding?

Ans. Utilizing a braiding machine instead of relying on manual braiding offers a multitude of advantages, resulting in increased production, accuracy, and efficiency. In contrast to manual braiding, braiding machines provide automated operation, significantly reducing manufacturing time. These machines have the ability to swiftly and uniformly interlace fibers or wires, leading to higher production rates and expedited project completion. This heightened productivity empowers businesses to meet tight deadlines and fulfill large orders with greater ease.

Compared to manual braiding, which can be subject to variation and human error, braiding machines deliver consistent and reliable results. This precision is particularly valuable in industries that demand strict adherence to specifications, such as aerospace or medical device manufacturing, where quality and accuracy are of utmost importance. Additionally, braiding machines exhibit versatility and can handle a wide range of materials, braid sizes, patterns, and designs. This flexibility allows for the creation of customized solutions tailored to specific purposes or customer requirements, further enhancing the overall value and appeal of the braided products.

Q. Is braiding machines expensive?

Ans. The cost or price of braiding machines varies depending on criteria such as machine type, specifications, capabilities, and manufacturer. Braiding machines are frequently expensive because to their sophisticated design, specialized features, and the requirement for precision engineering.

Manufacturers & Suppliers of Braiding Machine

Company Name | Member Since |

|---|---|

Deep International Mumbai, India | 14 Years |

Taizhou Winstrong Special Net Co., Ltd. Taizhou, China | 11 Years |

Geeta Lighting Industries Ballabgarh, India | 11 Years |

Shiv Shakti Engineering Works Faridabad, India | 9 Years |

Srichand Engineering & Moulding Co. Ahmedabad, India | 8 Years |

Parovi Machines Kundli, India | 8 Years |

Jayson Engineering & Mfg. Co. Ahmedabad, India | 8 Years |

Susmatex Machinery Ahmedabad, India | 6 Years |

Texzium International Pvt Ltd Delhi, India | 6 Years |

Mahesh Twisto Tech Pvt. Ltd. Bhavnagar, India | 2 Years |

Popular Products