Flexo Printing Machinery

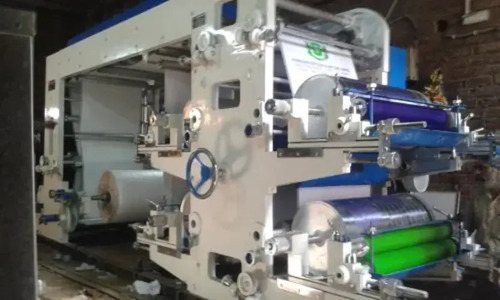

(735 products)High Insulation Four Colour Flexo Printing Machine

MOQ1 , Unit/Units

Product TypePrinting Machines

Weight (kg)4-6 Tonne

ComputerizedNo

AutomaticYes

Voltage280-440 Volt (v)

FeatureHigh Insulation, Compact Structure

Non Woven single colour Flexo Printing Machine

MOQ1 Unit/Units,

Payment TermsCash on Delivery (COD)

Supply Ability1 Per Day

Delivery Time1 Days

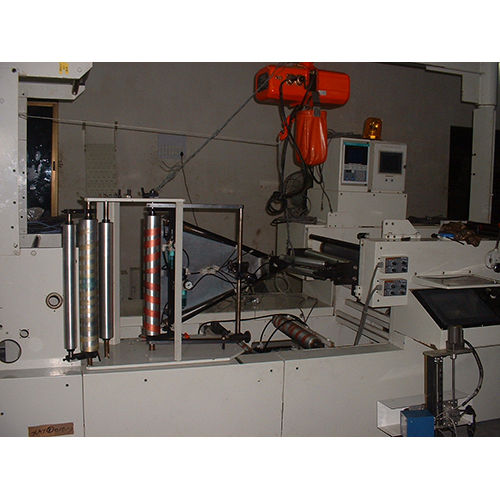

Automatic Four Colour Paper Cup Flexographic Printing Machine

Price: 1000000 INR/Set

MOQ1 Set/Sets

ColorOther

MaterialStainless steel

FeatureLess Power Consumable, Other, Durable, Highly Efficient, Rust Proof, Heavy Duty Machine

ComputerizedYes

Automatic GradeAutomatic

Control SystemPLC Control

Labh Projects Pvt. Ltd.

Ahmedabad

Super Seller

Super Seller4 Years

Double Colour Paper Flexo Printer Machine - Stainless Steel Ink Tray, 5 H.P. Motor & Variable Speed A.C. Drive | Manual Control System, Custom Capacity, Suitable for Cardboard & Kraft Paper Printing

Price Trend: 510000.00 - 1330000.00 INR/Set

MOQ1 Set/Sets

Product TypeDouble Color Flexo

General UseTo use Cardboard & paper Printing

Printing MaterialKraft Paper

CapacityCustom Kg/hr

ComputerizedNo

AutomaticNo

Senior Paper Packing Machinery Mfg. Co.

Amritsar

4 Colors 1 Flexo Printing Machine - Feature: High Insulation

Price: 1800000 INR/Set

MOQ1 Set/Sets

Product Type4 Colors 1 Flexo Printing Machine

General UseIndustria

AutomaticYes

Printing Plate Lifting SystemHydraulic Press Control

FeatureHigh Insulation

Kamtronics Technology Private Limited

New Delhi

Trusted Seller

Trusted Seller11 Years

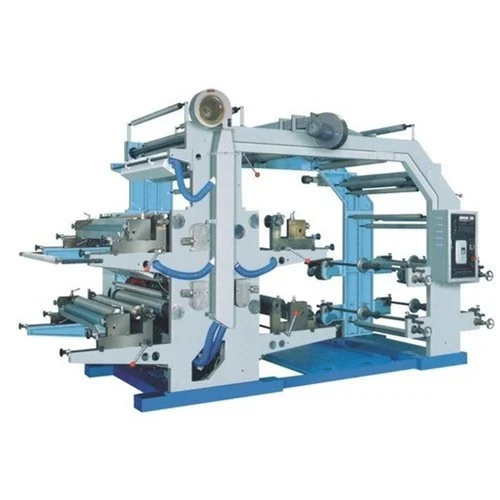

Flexographic Printing Machines - Electric Powered, Rust Free, Corrosion Resistant | Automated Operation, Compact Structure, Lower Energy Consumption, Available in White, Blue, Red

Price: 2500000 INR/Unit

MOQ1 Unit/Units

ColorWhite, Blue, Red

Product TypeFlexographic Printing Machines

General UseIndustrial

ComputerizedNo

AutomaticYes

Control SystemPLC Control

Blue Flexo Printer Slotter Combine Machine

Price: 1100000 INR/Unit

MOQ1 Unit/Units

ColorBlue

Product TypeFlexo Printer Slotter Combine Machine

TypeFlexo Printer Slotter Combine Machine

AutomaticYes

Voltage220-440 Volt (v)

FeatureHigh Efficiency

Shree Krishna Engineering Works

Surat

Flexo Printing Machine - High Precision, Compact Design | Advanced Print Technology, Versatile Media Compatibility

Product DescriptionFlexo Printing Machine

Flexo Printing Machinery Capacity: 10000 Pieces Per Hour Ton/Day

Price Trend: 400000.00 - 1350000.00 INR/Unit

MOQ1 Unit/Units

TypeOther

MaterialMild Steel

Capacity10000 Pieces Per Hour Ton/day

ComputerizedNo

Voltage280-420 Volt (v)

Weight (kg)4-6 Tonne

Flexo Press Machine

Product DescriptionWe are making and supplying of Flexo Press Machines from Chennai, Tamil Nadu, India. The Proflex range of modular printing press equipment are available with line shaft or Servo drive technology. We have a wide range of options for specialised production applications.\015\012Combination drying syste

Flexo Longway Board Paper Printer - Color: Green

Price: 1975500 INR/Unit

MOQ1 Unit/Units

ColorGreen

Product TypeFlexo Longway Board Printer

General UseIndustrial

TypeBoard Printer

Weight (kg)4000-8000 Kilograms (kg)

ComputerizedNo

Flexo Board Printer Sheet Fed - Graded Steel Frame, Heavy Duty Ink Rollers | Variable Speed up to 2000 Impressions per Hour, Compatible with Water Base and Thinner Base Inks

Product DescriptionWe manufacture, export and supply Flexo Board Printer Sheet Fed to our customers in New Delhi, Delhi, India to our customers. Salient Features of Flexo Board Printer Sheet Fed :- Main Frame made from graded steel held together by means of heavy cross supports. Rubberized ink rollers. The Machine

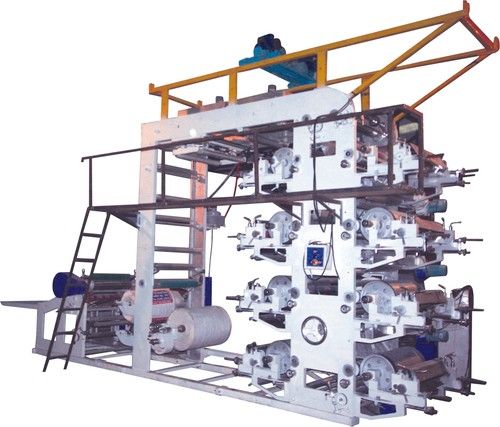

Six Flexo Color HDPE Printing And Online Cutting Machine

Price Trend: 1800000.00 - 2500000.00 INR/Number

MOQ1 Number

Supply Ability1 Per Month

Delivery Time1 Months

Sharda Industries

Navsari

Trusted Seller

Trusted Seller5 Years

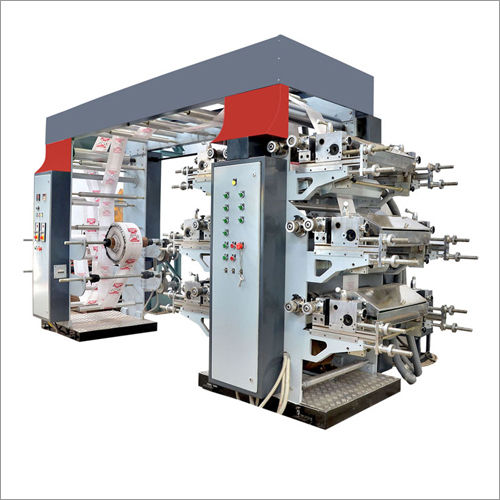

4-6 Color Flexo Printing Machine

Product DescriptionKnowing us as a reputed firm, we are engaged in manufacturing, supplying, importing and exporting a wide range of 4-6 Color Flexo Printing Machine in Bengaluru, Karnataka, India. AV-921 is an economical and environment friendly printer for printing cup paper. It is suitable for both single and doubl

White Four Colour Printer Slotter

Price: 3500000 INR/Unit

MOQ1 Unit/Units

ColorWhite

Product TypePrinting Machine

ComputerizedNo

AutomaticNo

FeatureLower Energy Consumption, High Efficiency

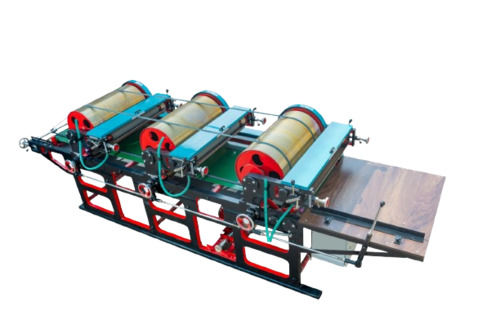

3 Colour Unique Flexographic Printing Machine - Capacity: 1500 T/Hr

Price: 380000.00 INR/Unit

MOQ1 Piece/Pieces

Product TypeFlexographic Printing Machine

General UseIndustrial

TypePrinting machine

Capacity1500 T/hr

Weight (kg)700 Kilograms (kg)

ComputerizedNo

Closed Doctor Blade Chamber Type Flexo Printing Machine - Color: White

Price: 55000000 INR/Piece

MOQ1 Piece/Pieces

ColorWhite

Product TypeClosed Doctor Blade Chamber Type Flexo Printing Machine

General UseIndustrial

AutomaticYes

FeatureHigh Efficiency

Ishan International

Ahmedabad

Trusted Seller

Trusted Seller6 Years

Yes Fully Servo Controlled Narrow Web Flexographic Label Printing Machine

Price: 18000000 INR/Unit

MOQ1 Unit/Units

ColorYes

Product TypeFully Servo Controlled Narrow Web Flexographic Label Printing Machine

General UseIndustrial

AutomaticYes

Control SystemPLC Control

Voltage75 Horsepower (HP)

Webtech International Machineries

Faridabad

MTM 474 - Industrial Flexo Machine, Automatic PLC Control for High Efficiency, Any Color Option

MOQ1 Unit/Units

Product TypeMTM 474 - Flexo Machine

General UseIndustrial

AutomaticYes

Control SystemPLC Control

FeatureHigh Efficiency

ColorAny Color

Safire Machinery Company Private Limited

Chennai

MS Flexo Printing Machine - Mild Steel, Semi-Automatic, 240 Volt Power | Frequency Speed Control, 5-Year Warranty

Price: 500000 INR/Unit

MOQ1 Unit/Units

MaterialMild Steel

ComputerizedNo

Automatic GradeSemi-Automatic

Control SystemFrequency Speed Control

Power240 Volt (v)

Warranty5 Years

Sap Vardhman Machinery Private Limited

Delhi

Grey Three Color Flexo Paper Cum Board Printing Machine

Price: 1800000 INR/Unit

MOQ1 Unit/Units

ColorGrey

Product TypeFlexo Paper Cum Board Printing Machine

General UseIndustrial

TypeFlexo Paper Cum Board Printing Machine

ComputerizedNo

AutomaticYes

Supercut Engineers Private Limited

Mumbai

Flexo Printer - High-Speed Precision Printing Machine | Excellent Print Quality, Easy Maintenance, High Throughput, User-Friendly Operations

Product DescriptionIn order to cater to the demands of the industry, we manufacture and export Flexo Printer. This printer is extensively used in packaging and

Sun-up (india ) Paper Board Machinery (p) Ltd.

Bhiwandi

Non Woven Flexo Printing Machine - General Use: Industrial

Price: 1400000 INR/Unit

MOQ1 Unit/Units

Product TypeNon Woven Flexo Printing Machine

General UseIndustrial

ComputerizedNo

AutomaticYes

Voltage220-240 Volt (v)

White Flexo Graphic Printing Sleeves

MOQ1 Piece/Pieces

Product TypeFlexo Graphic Printing Sleeves

ComputerizedYes

AutomaticYes

FeatureLower Energy Consumption

ColorWhite

Non Woven Fabric Printing Machine - 8 Color Capability, Web Width 22, Speed Up to 150 m/min | User-Friendly Design, Automatic Tension Control, Versatile Substrate Compatibility

Price: 1200000.00 INR/Plant

MOQ1 Plant/Plants

Product TypePRINTING M/C

General UsePRINTING

Printing MaterialOther

Capacity150 Kg/hr

Mechanical Speed60 m/m

Voltage220 -440 BOTH Watt (w)

ROLL TO SHEET FLEXO PRINTING MACHINE FOR CORRUGATED BOXES

Price: 1671000 INR/Unit

MOQ01 Unit/Units

ColorSingle to multicolor

Product TypeROLL TO SHEET

General UseFOR CUTTING AND PRINTING CRAFT AND DUPLEX PAPER

Printing MaterialKraft Paper

Capacity35000 P/H

Weight (kg)3500 Kilograms (kg)

Romco Offset Private Limited

Faridabad

Premium Seller

Premium Seller2 Years

6 Colour Flexo Printing Machine

Price: 1800000 INR/Unit

MOQ1 Unit/Units

Capacity1000 Kg/hr

ComputerizedNo

AutomaticYes

Two Colour Flexo Carton Printing Machine, Max Printing Length: 0-500 (mm)

Product DescriptionTwo Colour Flexo Carton Printing Machine

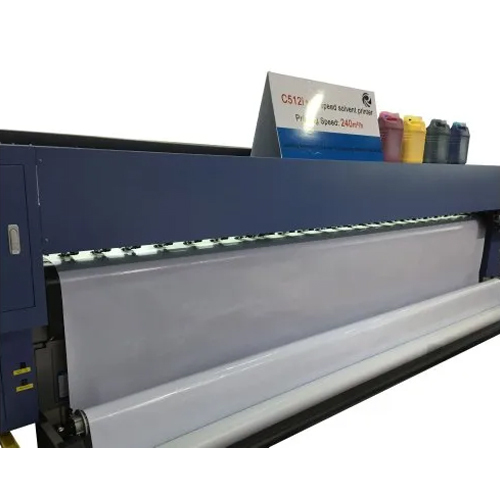

Black Lotus Konica 512I Automatic Digital Flex Printing Machine

Price: 1300000 INR/Unit

MOQ1 Unit/Units

ColorBlack , Silver

Product TypeLotus Konica 512i Automatic Digital Flex Printing Machine

Printing MaterialPVC

ComputerizedNo

AutomaticYes

Control SystemPLC Control

Turnkey Printing Solutions Pvt. Ltd.

Greater Noida

Latest From Flexo Printing Machinery

Innovative Flexotech Flexo Printing Machinery

By:

Innovative Flexotech Pvt. Ltd.

Pp Hdpe Bags Flexo Printing Machinery

By:

Jakplast Technology

Flexo Printing Machinery For Corrugated Box

By:

Cangzhou Yiteng Imp &exp Trade Co.,ltd

KARNAVATI Flexo Printing Machinery

By:

Karnavati Woven Sack Industries

Vulcan Flexo Printing Machinery

By:

Vulcan Polyprint

Flexo Printing Machine

By:

Simran Engg. Works

Flex Printing

By:

Ensign Print Solutions India Pvt. Ltd.

Printing Flexographic Machine

By:

H. V. Shiv Foundry

Explore More Cities

Ready To Ship Flexo Printing Machinery

Flexo Printing Machinery and How Does it Work

Flexo printing machines are industrial-class print technologies that are equipped with a flexible printing plate typically manufactured by using synthetic materials such as rubber and photopolymer with the help of which printing ink is transferred to substrates such as paper, films, and plastic. These high-speed printing solutions are widely used to make elegant prints on cardboard boxes, plastic labels, paper bags, and many more. The high printing speed makes them cost-effective for large printing volumes.

These industrial machines are equipped with a series of mechanical components such as anilox rollers, blades, press, and printing plates that function together to make high-quality prints. The cylinder holds the image plate that carries the design that is going to be printed. This plate is then passed through an anilox roller which applies ink and the excess ink is swept away with the help of a doctor's blade. After that, the press mechanism presses the substrate against the printing plate to transfer the design. The print sheet is then passed through a drying system to prevent ink smudging.

Different Types of Flexo Printing Machinery Available on the Market

Flexographic Printing Machines can be classified into various types as per their sizes, control types, and application where they are going to be used. Some of the popular types are mentioned below:

Non-Woven Flexo Printing Machines: These are specially designed to make prints on thermally or chemically bonded non-woven fabrics. They are in high demand within applications such as bag making, hygiene products, medical products, and industrial materials.

High-Speed Flexo Banner Printers: These industrial units are used to make multicolor graphics and text on synthetic sheets to make high-quality banners, large posters, and other flexible print media. They are in high demand within printers and are commonly used in the advertising and signage industries.

On-Line Flexographic Printing Machines: These printing units are used to make prints on materials with narrow webbing. These are compatible with various materials, such as plastic, paper, and cardboard.

CI Flexo Presses: Also known as central impression printing machines, these printing units are usually used to print large continuous substrates. They are in high demand due to their capability to print in multiple colors.

Benefits of Using Flexo Printing Machinery

Flexo Printing Machines are popular within various industrial sectors due to the following advantages:

Large Printing Volume: Flexo printing machines are equipped with high-speed drives and advanced technologies that make high-quality prints in large quantities with low ink consumption, which makes them suitable for large-scale printing jobs.

Compatibility: One of the most important benefits of these machines is that they are capable of making print on various types of substrate materials such as plastic, paper, metallic foils, and cardboard.

High-quality prints: these machines produce prints with excellent color saturation and sharpness without any risk of ink smudging.

Environmentally friendly: Flexo-printing machines use water-based or UV-curable inks that do not emit any volatile or toxic compounds that result in high eco-friendliness.

Cost-effective: The low power consumption, less use of ink, and zero material wastage make them economical for small as well as large-scale printing jobs.

Common Applications of Flexo Printing Machinery

Flexo printing machines are high-performance printing technologies that can be used in several industrial applications:

Packaging: The capability to print materials such as cardboard, plastic films, metal foils, paper, and others make them suitable to print packaging materials for industries like food, pharmaceutical, medicine, cosmetic, agriculture, and many more.

Labels and tags: These machines are ideal to create product tags and labels for branding and information purposes.

Bag Making: Flexo printing machines can be used to print non-woven fabrics and plastic sheets which make them ideal for printing shrink sleeves, non-woven bags, plastic pouches, and re-sealable bags.

Wallpaper: The continuous print capabilities of these make them suitable to print elegant images and patterns over wallpapers used for the interior decoration for homes.

Corrugated containers: These industrial printing machines can be used to print corrugated cardboard containers for branding purposes to make them useful in e-commerce and retail.

Future of Flexo Printing Machinery

The future of any industrial machines depends on the long-term benefits they will provide. In the case of flexo printing machines, these printing solutions are highly advantageous in various industrial sectors, resulting in their bright future for printing applications:

Increased Automation: The fully automated and semi-automated variants of these printing machines are highly demanding due to quick printing, zero wastage, and less labor force.

Digitalization: It is expected to see more digital printing technologies within flexo printing machinery that will allow operators to make intricate design patterns with high print quality and greater flexibility.

Customization: These machines are well suited to provide personalized print solutions that make them in high demand for a large market of e-commerce businesses.

Integration & compatibility with Other Technologies: The smart and intelligent programmable control systems and technologies such as AI when combined with the flexo printing process will enhance the printing capabilities.

Eco-friendliness: As we are finding ways to use the environment-friendly system for the safety of the atmosphere, the flexo printing industry is no exception as they use non-toxic and recyclable materials for printing processes.

FAQs: Flexo Printing Machinery

Q. What are the main components of flexo printing machinery?

Ans. Flexo printing machines are industrial-grade printing machines that are equipped with several mechanical and automation components. The mains parts of these machines are:

- Printing plates: These flat elements are fabricated by using polymeric materials. They carry a design which can be a text or image to be printed on substrates.

- Anilox rollers: These components are responsible for efficiently transferring inks to the printing plates.

- Printing cylinder: This cylindrical spare is designed to apply pressure on printing plates to transfer print designs onto the substrate.

- Doctor blade: It is used to remove excess ink from an anilox roller to prevent the risk of ink smudging.

- Ink fountain: It is a storage unit that carries ink and supplies it to the anilox roller.

- Drying mechanism: To ensure quick drying of ink flexo printing machine comes with radiation-based curing systems that improve the print quality.

Q. What is the average cost of flexo printing machinery?

Ans. There are many different types of flexo printing machines available in the market. The price range of these industrial machines varies according to their sizes, features, power ratings, printing speeds, and print capabilities. The estimated range of average cost of flexo printing machinery in India is between 500000 to 3500000 INR per unit. Apart from the buying cost, other additional costs may be included, such as training, maintenance, installation, and repairs.

Q. What factors should be considered when selecting a flexo printing machine?

Ans. Choosing the right flexo printing machine for your business may be a challenging task. There are various factors that one needs to keep in mind while selecting the right machine for you:

Substrate material: Consider the types of materials you are going to print. If you have a good budget then it is advisable to select a machine that is capable of printing various types of substrates such as plastic, paper, and metal.

- Printing volume: this factor needs to be considered as per the size of your industrial facility.

- Printing width: the width of the substrate you are going to print will determine the size and type of machine you will need.

- Features: Always go for automated and integrated technologies that can be easily updated.

- Budget: Consider your budget and machine requirements before selecting your machine model.

Q. What is the typical lifespan of flexo printing machinery?

Ans. The service life of flexo printing machines depends on several factors which include application areas, daily work hours, maintenance and others. Usually, these machines are capable of operating for a longer run. The proper care and servicing of the offered machines further increase the service life of the machine for up to 5 years. Servicing factors such as lubrication, cleaning, and replacement of worn components also result in increased service life.

Manufacturers & Suppliers of Flexo Printing Machinery

Company Name | Member Since |

|---|---|

Friends Engineering Corporation New Delhi, India | 22 Years |

Mohindra Mechanical Works New Delhi, India | 21 Years |

Monu Graphics Faridabad, India | 21 Years |

Senior Paper Packing Machinery Mfg. Co. Amritsar, India | 20 Years |

Perfect Machinery New Delhi, India | 14 Years |

Kamtronics Technology Private Limited New Delhi, India | 11 Years |

Micro Engineers (India) Vasai, India | 10 Years |

Samir Machinery Vadodara, India | 9 Years |

Unique Fluid Controls Coimbatore, India | 8 Years |

Sap Vardhman Machinery Private Limited Delhi, India | 8 Years |

Popular Products