Lamination Machinery

(1872 products)Strength Testing Machine - Material: Mild Steel

MOQ1 Piece/Pieces

TypeStrength Testing Machine

MaterialMild Steel

Power220

Power SourceElectric

UsageIndustrial

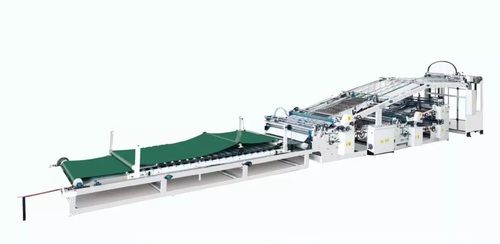

White Film Laminating Machine

MOQ1 Set/Sets

Product TypeFilm Lamination Machine

Voltage66 Watt (w)

Weight (kg)4800 Kilograms (kg)

Dimension (L*W*H)8720 x 2380 x 2660 Millimeter (mm)

ColorWhite

Tymi Machinery Industry Co. Limited

Taipei

Automatic Solvent Less Extrusion Lamination Plant

Price: 1000000 INR/Set

MOQ1 Set/Sets

ColorOther

MaterialStainless steel

FeatureHeavy Duty Machine, Durable, Rust Proof, Highly Efficient, Less Power Consumable, Other

ComputerizedYes

Automatic GradeAutomatic

Control SystemPLC Control

Blue Semi Automatic Film Lamination Machine

Price Trend: 1600000.00 - 2500000.00 INR/Piece

MOQ1 Unit/Units

Product TypeFilm Lamination Machine

MaterialMild steel

ComputerizedYes

Automatic GradeAutomatic

Control SystemPLC Control

Drive TypeElectric

Thermal Lamination Machine Tlm 520E19.5 - Automatic Grade: Automatic

Price: 340000 INR/Piece

MOQ1 Piece/Pieces

ColorWhite

Product TypeOther, Thermal Lamination Machine

MaterialSteel

ComputerizedNo

Automatic GradeAutomatic

Drive TypeElectric

Automatic Silver Paper Lamination Machine With Cutter

Price: 325000.00 INR/Piece

MOQ1 Piece/Pieces

Product TypePaper Lamination Machine

ComputerizedNo

Automatic GradeAutomatic

Control SystemFrequency Speed Control

Drive TypeElectric

Heating SystemOther

Paper Lamination Machine - Metal Build, Automatic Operation | Electric Drive, Non-Computerized Functionality

Price: 190000.00 INR/Set

MOQ1 Piece/Pieces

Product TypePaper Lamination Machine

MaterialMetal

ComputerizedNo

Automatic GradeAutomatic

Drive TypeElectric

Senior Paper Packing Machinery Mfg. Co.

Amritsar

1100Mm Hot And Cold Lamination Machine - Automatic Grade: Semi Automatic

Price: 115000 INR/Unit

MOQ1 Piece/Pieces

MaterialMetal

Automatic GradeSemi Automatic

Power SourceElectric

Voltage220 Volt (v)

Weight (kg)70 Kilograms (kg)

Dimension (L*W*H)1350x600x1250 Millimeter (mm)

Automatic 220V Laminating Press Machine

Price: 400000 INR/Unit

MOQ1 Unit/Units

Product TypeOther, Laminating Press Machine

MaterialMetal

ComputerizedNo

Automatic GradeAutomatic

Control SystemHuman Machine Interface

Automatic Paper Lamination Machine With Cutting

Price Trend: 230000.00 - 280000.00 INR/Piece

MOQ01 , Piece/Pieces

Materialpaper

ComputerizedYes

Automatic GradeAutomatic

Semi Automatic Excelam Xl 18 Lamination Machine

Price: 18000 INR/Unit

MOQ10 Unit/Units

ColorBlack

Product TypeFilm Lamination Machine

MaterialMetal

ComputerizedNo

Automatic GradeSemi Automatic

Control SystemHuman Machine Interface

Blue & White Automatic Glue Laminating Machine

Price: 350000 INR/Unit

MOQ1 Unit/Units

ColorBlue & White

MaterialMetal

Automatic GradeSemi Automatic

Voltage380 Volt (v)

WarrantyYES

Dts Machinery And Trading Private Limited

Vellore

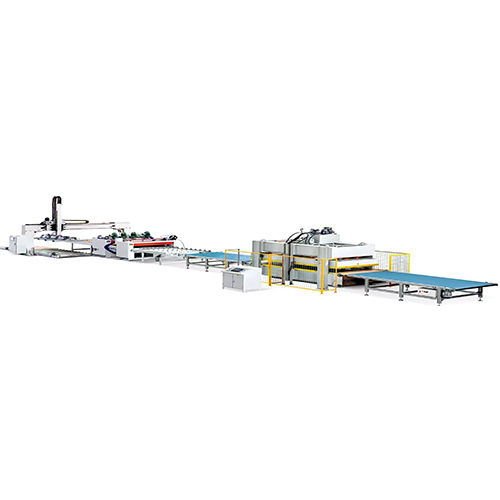

Blue / White Automatic Extrusion Coating Lamination Machine

Price: 5551000 INR/Unit

ColorBlue / White

MaterialLD / PP

Automatic GradeAutomatic

Drive TypeElectric

Power SourceElectric

Voltage52-145 kw Watt (w)

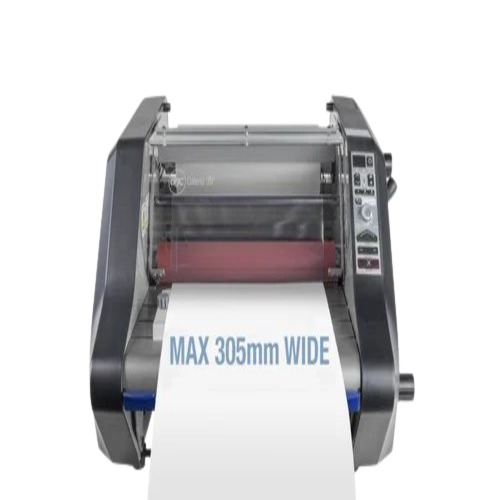

High Performance Lamination Machines Ne-360Mini

Product TypeCold/Hot Laminating Machine

FeatureSimple Control, High Performance, Low Noise, Lower Energy Consumption, ECO Friendly, High Efficiency

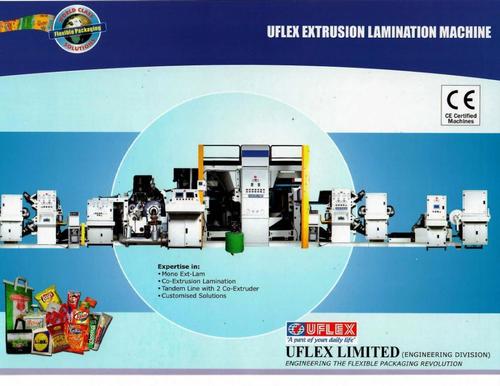

Uflex Extrusion Lamination Machine - 1000mm Dia. x 1300mm Width, AC Servo Motor with Digital Drive, Automatic Tension Control System, Heavy Duty Steel Frame, Dual Direction Cutter

Price: 75000000 INR/Piece

MOQ1 Piece/Pieces

Payment TermsTelegraphic Transfer (T/T), Letter of Credit (L/C), Cash in Advance (CID)

Delivery Time12-16 Week

Main Domestic MarketAll India

Uflex Limited (engineering Division)

Noida

Trusted Seller

Trusted Seller24 Years

Blue Silver Paper Roll To Roll Fully Automatic Lamination And Slitting Machine

Price: 125000 INR/Piece

MOQ1 Piece/Pieces

ColorBlue

Product TypePaper Lamination Machine

Automatic GradeAutomatic

Power SourceElectric

Weight (kg)200 Kilograms (kg)

Laminating Machine - Electric Semi-Automatic Design | High Temperature Resistant Structure, Versatile for Textiles and Non-Woven Fabrics

Product DescriptionLaminating Machine\015\012\015\012Condition: New\015\012 Application: Textiles\015\012 Packaging Type: Case\015\012 Packaging Material: plywood case\015\012 Automatic Grade: Semi-Automatic\015\012 Driven Type: Electric\015\012 Place of Origin: China (Mainland)\015\012 After-sal

Wuxi Honghao International Co.,ltd

Wuxi

Trusted Seller

Trusted Seller11 Years

Automatic Sd460 Datacard Laminator

Price: 225000 INR/Piece

MOQ1 Piece/Pieces

ColorBlack

Product TypeOther, Sd460 Datacard Laminator

ConditionNew

MaterialPlastic

DimensionsCustiomize Centimeter (cm)

Drive TypeElectric

Thinkbotic Technology Private Limited

Delhi

Silver Paper Plate Lamination Machine - Aluminium Foil Paper, Up to 8 Inches , 1000 pcs/hr High Production Capacity

Price: 125000 INR/Piece

MOQAny order Piece/Pieces

Payment TermsCash in Advance (CID)

Delivery Time7-10 Days

Main Domestic MarketAll India

Vinpat Machinery (opc) Private Limited

Lucknow

V350 Thermal Laminator - Stainless Steel, 530x210x220mm | Automatic Grade with Hot & Cold Film Options, Frequency Speed Control, 1.1m/min Speed, 700W Power

Price: 20000.0 INR/Piece

MOQ1 Piece/Pieces

Drive TypeElectric

Voltage220V / 50/60 HZ Volt (v)

Weight (kg)NW 7 KG / GW 8 KG Kilograms (kg)

Dimension (L*W*H)530*210*220 Millimeter (mm)

Speed1.1 Meter/Minute m/m

Paper Plate Lamination Making Machine - Automatic Grade: Semi Automatic

Price: 150000 INR/Unit

MOQ1 Unit/Units

MaterialStainless Steel

ComputerizedNo

Automatic GradeSemi Automatic

Control SystemFrequency Speed Control

Drive TypeElectric

Heating SystemTubular Heater

Lamination Machines - Durable Construction, Customizable Dimensions | Ideal for Various Sectors, Certified Quality Assurance

Product DescriptionLamination Machines are mostly used in various sectors for lamination of different kinds of products. These are procured from the certified dealers in the market. We offer these to our customers at nominal prices in the markets. Our range is checked on various attributes to offer unmatched range to

Kt Automation Private Limited

Vadodara

Three Feeder Automatic 5 Ply Flute Laminator Power Source: Electric

Product Type5 Ply Flute Laminator, Other

ComputerizedNo

Automatic GradeAutomatic

Control SystemPLC Control

Drive TypeElectric

Power SourceElectric

Automatic Single Layer Hot Press Machine

Price: 1400000 INR/Unit

MOQ1 Unit/Units

Product TypeHot Press Machine, Other

MaterialMetal

ComputerizedNo

Automatic GradeAutomatic

Power SourceElectric

FeatureECO Friendly, Simple Control, High Performance

Nandini Machine And Tools

Pune

Automatic Electric Id Card Lamination Machine

Price: 30500 INR/Unit

MOQ1000 Unit/Units

ColorBlack

Product TypePVC Laminating Machine

MaterialMetal

ComputerizedNo

Automatic GradeAutomatic

Control SystemHuman Machine Interface

Efficient Economical Lamination Machine - Insulated Glass Wool Panel, Digital Temperature Control | Two Roll Surface Rewinder with Slipping Clutch Assembly, SRA Web System for Web Control

Product DescriptionWe are engaged in manufacturing, distributing and supplying of Efficient Economical Lamination Machine in Ahmedabad, Gujarat, India. \015\012Doctor blade and Nip Roller. Fully insulated glass wool sheet fitted in the panel (Top side and Bottom) for controlling heat loss. One and one slit type air fl

Automatic P-Series Pur Flat Lamination

MOQ1 Unit/Units

Product TypeOther, P-Series Pur Flat Lamination

MaterialSS

ComputerizedYes

Automatic GradeAutomatic

Drive TypeElectric

Power SourceElectric

Glades Technologies Limited Liability Partnership

New Delhi

Automatic Roll to Roll Lamination Machine - 45 to 500 GSM Capacity, 20-25 Mtrs/Min Speed | Electric Drive, PLC Control, 1 Ton/Day, 1 Year Warranty, Quiet Operation

Price: 345000 INR/Unit

MOQ1 Unit/Units

ColorGreen

Product TypeFilm Lamination Machine

MaterialSilver, Green

ComputerizedYes

Automatic GradeAutomatic

Control SystemPLC Control

Automatic Film Lamination Machine - Color: White

Price: 350000 INR/Unit

MOQ1 Unit/Units

ColorWhite

Automatic GradeAutomatic

Drive TypeElectric

Power SourceElectric

Voltage220-440 Volt (v)

Weight (kg)1.2 Tonne

Royal Business Industries

Kolkata

Premium Seller

Premium Seller1 Years

Latest From Lamination Machinery

Eco Friendly and High Efficiency Extrusion Lamination Machinery

1000000 INR

By:

Sukant Electronics Pvt. Ltd.

Pouch Lamination Machine

By:

Gb Tech (india)

RJ Lamination Machinery

By:

Rj Infotech

Heat Lamination Machine

By:

Gobind Industries

Static Mixer Holder

By:

Rashi Equipments Pvt. Ltd.

Explore More Cities

Ready To Ship Lamination Machinery

Overview of Lamination Machinery

Printing, packaging, and manufacturing are just a few of the businesses that depend heavily on lamination equipment. It is a procedure that includes joining several layers of materials to form a single composite structure that offers improved strength, toughness, and defense. This procedure is automated and streamlined using lamination machines, which increases its effectiveness and lowers its cost. A crucial tool in many sectors, the lamination machine makes it easier to fuse materials to increase their sturdiness and aesthetic appeal. Businesses can select the ideal lamination machine to match their unique requirements and produce laminated items quickly and with excellent quality thanks to the various types and technologies that are available.

Importance and Applications of Lamination Machine

Lamination machine is very important in many different sectors and has a variety of uses. Applying a protective layer to different materials is the lamination process, which has advantages including greater durability, improved look, and improved resistance to wear and tear. It is essential to obtain these benefits successfully and efficiently.

A lamination machine is crucial for a number of reasons, including its capacity to safeguard and preserve printed goods like papers and photos. These goods are protected from moisture, dust, and other potentially damaging environmental conditions by being enclosed within a laminated covering.

A lamination machine is essential to the industrial sector because it makes it possible to create composite materials with exceptional strength and adaptability. It is essential for producing parts and buildings with increased strength, outstanding heat resistance, and trustworthy corrosion protection, which helps sectors including aerospace, automotive, and construction.

Additionally, lamination equipment is useful for producing badges, identity cards, and security documents. These goods' resistance to deterioration, manipulation, and counterfeiting is considerably boosted by laminating them.

Components of the Lamination Machine

The efficient and successful lamination process is ensured by a number of vital parts of the lamination machine. These parts are essential at various stages, from the initial processing of the material through the finished laminated product.

- System for heating: The heating system, which delivers regulated heat to activate the glue and aid material bonding, is one crucial component. The kind of lamination equipment will determine whether heated rollers or heated plates are used. The heating system makes sure that temperatures are distributed evenly and consistently, which promotes the best possible adhesion between the layers.

- Pressure Rollers: Another key part of laminating equipment is pressure rollers. These rollers exert pressure on the materials being laminated, guaranteeing a solid connection and getting rid of air bubbles. They aid in distributing pressure evenly throughout the surface.

- Adhesive Application Mechanism: A variety of adhesive application techniques are used by lamination equipment. While the adhesive is usually pre-applied to one side of the laminate sheet in roll laminators, it is retained within the laminating pouch in pouch laminators. The mechanism used to apply the glue makes sure that it is distributed precisely and evenly, resulting in adequate bonding between the layers.

- Feeding Mechanism: A feeding mechanism is built into lamination equipment to ensure that materials enter the process smoothly and uniformly. This system, which might include rollers, belts, or guides, aids in precisely arranging the materials and controls how quickly they pass through the laminating unit.

- Control Panel and Sensors: A control panel with user-friendly interfaces is frequently included with lamination equipment. Based on the materials being laminated, operators can change variables including temperature, speed, and pressure on this panel. To ensure safe and effective functioning, sensors are also included to monitor important factors like temperature.

- Cooling System: A cooling system is used after lamination to quickly cool the laminated materials. This guarantees the glue will cure quickly and aids in preserving the integrity of the layered structure. Fans or cooling rollers are examples of cooling devices that help with solidification and keep laminated materials from adhering to one another.

Types of Lamination Machinery

There are several types of lamination machines, each of which is made to accommodate certain lamination requirements and materials. These numerous pieces of machines are adaptable and effective in attaining the appropriate lamination results in a variety of sectors.

- Roll Laminators: Both small-scale and large-scale lamination applications frequently employ roll laminators. To melt glue and bind items together, they use hot rollers. Roll laminators are best suited for laminating flat materials including paper, photos, posters, and other types of flat media.

- Pouch Laminators: Pouch laminators are portable, handy equipment used for laminating jobs of a smaller scope. They make use of adhesive-coated, pre-sealed laminating pouches.

- Large-Format Laminators: To handle bigger materials, large-format laminators were created. They are extensively utilized in fields including printing, advertising, and sign-making.

- Industrial laminators: These powerful machines are utilized for labor-intensive and high-volume laminating applications. They are used often in sectors like packaging, manufacturing, and construction since they are made for large-scale production.

- Cold Laminators: Heat is not necessary for lamination with cold laminators. Instead, they make use of self-adhesive laminating films or pressure-sensitive adhesives. For materials that could be heat-sensitive or for applications where heat is not wanted, cold laminators are appropriate.

- Multifunctional Laminators: Laminating equipment with extra tasks may be found in multifunctional laminators, which are adaptable devices. These devices frequently include capabilities for cutting, trimming, and even printing.

FAQs: Lamination Machinery

Q. How to use a Lamination Machine?

Ans: Utilizing a laminating machine is a basic procedure that just calls for a few easy actions. Make sure the device is connected and switched on first. The temperature and speed parameters should then be modified by the kind of materials being laminated. Wait until the machine reaches the required temperature. Place the object to be laminated into the laminating pouch or feed it into the machine together with the laminating film once the machine is ready. The heated rollers in the machine will automatically run the object through them, activating the glue and joining the materials. To guarantee adequate adhesion once the object has been through the machine, let it cool down. Finally, if required, cut any extra laminate.

Q. Which type of lamination machine is best?

Ans: A roll laminator is a common option for ordinary laminating applications. Roll laminators are adaptable and can work with a variety of materials. They are available in a variety of shapes and sizes to meet a range of laminating requirements, from modest projects to large-format graphics. Using heated rollers to melt glue and fuse materials together, roll laminators provide a secure and polished surface. Roll laminators are frequently preferred by businesses, schools, and offices for their dependability and effectiveness in producing high-quality laminated outputs because of their flexibility, ease of use, and capacity to handle varying thicknesses.

Q. What is the cost of a lamination machine in India?

Ans: A lamination machine's price in India might change based on a number of variables, including the machine's kind, brand, features, and specs. Lamination machines are often offered at a variety of pricing points to accommodate various needs and budgets. Prices for entry-level products, such as pouch laminators, range from about INR 1,000 to 5,000. Roll laminators often cost more, ranging from about INR 10,000 to 50,000 or more, depending on the size and features, and provide greater variety and capabilities. Industrial-grade laminators can cost more, sometimes reaching INR 1 lakh, and feature more sophisticated functions and greater capacity.

Q. How to maintain a lamination machine?

Ans: A lamination machine's performance and longevity must be maximized by performing routine maintenance. You can guarantee the equipment operates at its best and lengthen its lifespan by routinely cleaning it. To ensure smooth operation and keep it in top shape, it is strongly advised to avoid the buildup of dirt, grime, and sticky residue on the rollers and surfaces. The functioning of the laminating machine as a whole is greatly impacted by the rollers, thus it is crucial to check them often for any symptoms of wear or damage. To avoid overheating and unneeded wear on the machine, it is also crucial to pay strict attention to the speed and temperature settings.

Manufacturers & Suppliers of Lamination Machinery

Company Name | Member Since |

|---|---|

Uflex Limited (Engineering Division) Noida, India | 24 Years |

Senior Paper Packing Machinery Mfg. Co. Amritsar, India | 20 Years |

Gb Tech (India) Delhi, India | 19 Years |

Kt Automation Private Limited Vadodara, India | 15 Years |

Khalsa Engineering Works Delhi, India | 12 Years |

Wuxi Honghao International Co.,Ltd Wuxi, China | 11 Years |

Accuweb Enterprises Ahmedabad, India | 10 Years |

Greentech Engineering Surat, India | 10 Years |

Jai Durge Industries Jaipur, India | 9 Years |

Bhakti Enterprises Mumbai, India | 9 Years |

Popular Products