Processing Machines & Equipment

(4186 products)Product Showcase

Creamer Mixer Blender Capacity: 1 T/Hr

MOQ1 Piece/Pieces

TypeCreamer Mixer Blender

MaterialStainless Steel

Capacity1 T/hr

ComputerizedNo

Voltage220/380 Volt (v)

Frequency (MHz)50 Hertz (HZ)

Miranda Automation Pvt. Ltd.

Navi Mumbai

Super Bonanza

Super Bonanza18 Years

Hopper With Screw Conveyor Weight: 50 Kilograms (Kg)

Price: 150000.00 INR/Unit

MOQ1 Unit/Units

TypeHopper With Screw Conveyor

Weight50 Kilograms (kg)

Sigma Instrumentation

Ahmedabad

15 Years

Super Premium

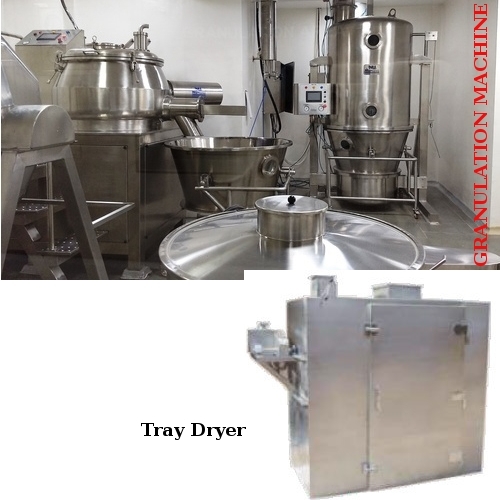

Super PremiumRising Film Evaporator - High Efficiency Design, Suitable for Heat Sensitive and Viscous Liquids, Flexible Conversion to Forced Circulation Evaporator

Product DescriptionWe are manufacturing a wide range of Rising Film Evaporator that ensure the flow of the liquid upward in a parallel flow. Due to the increased vapor mount, it forms a "climbing" film on the walls of a tube it creates turbulence in the liquid that is suitable for heat sensitive, highly viscous and mo

Advanced Drying Systems

Vasai

Super Bonanza

Super Bonanza20 Years

Automatic Octagonal Blender By Nu Pharma Engineers & Consultant

Price: 350000.00 INR/Set

MOQ1 Set/Sets

TypeOctagonal Blender

MaterialStainless Steel

ComputerizedYes

Automatic GradeAutomatic

Voltage220 Volt (v)

SizeStandard

Nu Pharma Engineers & Consultant

Ahmedabad

Super Bonanza

Super Bonanza12 Years

Apron Feeders - Heavy-Duty Steel, Optimal for Regulating Abrasive Materials | Versatile Models for Storage Application

Product DescriptionOur organization provide Apron Feeders in different models with different specifications. These Apron Feeders are extensively used to handle abrasive, heavy and lumpy material. The perfect place to install these Apron Feeders is under storage bin for regulating the feed material. We offer these Apro

Ecoman

Vadodara

Super Bonanza

Super Bonanza15 Years

Automatic Stainless Steel Electromagnetic Feeder Machine

Price: 96000 INR/Unit

MOQ1 Unit/Units

TypeElectromagnetic Feeder Machine

MaterialStainless Steel

ComputerizedNo

Automatic GradeAutomatic

Voltage220 Volt (v)

Frequency (MHz)50 Hertz (HZ)

Magna Tronix

Chennai

4 Years

Plough Mixer - Superior Quality for Blending and Mixing | Ideal for Pharmaceuticals, Foodstuffs, and Chemicals, Optional Heating and Cooling Jacket

Price: 225000 INR/Piece

MOQ1 Piece/Pieces

Product DescriptionWe manufacture, exports and supply superior quality Plough Mixer that are used for different blending, mixing and drying processes. The machines provide perfect homogeneous blends for dry, fine as well as coarse powders, grains and pastes.\015\012\015\012These mixers find application in industries

Ultra Febtech Private Ltd.

Ahmedabad

4 Years

Super Premium

Super PremiumColloid Mills - Stainless Steel, 50 Lit/hr - 7500 Lit/hr Capacity | Continuous Operation for Ultimate Dispersion, Closed Pressurized System, Adjustable Grinding Gap

Product DescriptionColloid Mills is suitable for continuous operation of ultimate dispersion with particle size reduction of pharmaceutical formulations, creams & cosmetics, ointments, food products etc., and the work is earned out in single pass under a closed and pressurized system with improved colour, reactivity

Chemech Engineering

Mumbai

21 Years

Rust Proof Solid Liquid Separator - Stainless Steel, 3000-4000 Lph Pump Capacity, 6500 RPM Basket Speed | Automatic Safety System, Fire Resistant, Easy to Operate, 12 Months Warranty

Price: 20000 INR/Case

MOQ1 Case/Cases

MaterialStainless Steel

ConditionNew

TypeRoller Conveyor

StructureRoller

ComputerizedNo

Automatic GradeAutomatic

Reidius Engitech Private Limited

Ahmedabad

7 Years

Grizzly Feeders - Mild Steel, Automatic Operation | High Efficiency, Long Operational Life, Easy Maintenance

MOQ1 Unit/Units

TypeGrizzly Feeders

MaterialMild Steel

ComputerizedNo

Automatic GradeAutomatic

Warranty12 Month

Siddharth Engineering Co.

Navi Mumbai

24 Years

Super Premium

Super PremiumDouble Cone Blender By Auto Power Pack

Price: 90000 INR/Piece

MOQ1 Piece/Pieces

TypeDouble Cone Blender

MaterialStainless Steel

Capacity300 Kg/hr

Automatic GradeSemi-Automatic

Voltage240V Volt (v)

WarrantyYes

Auto Power Pack

Puducherry

4 Years

Automatic Garbage Disposer

Price: 1850000 INR/Piece

MOQ1 Piece/Pieces

TypeGarbage Disposer

MaterialMild Steel

Capacity250 Kg/hr

ComputerizedNo

Automatic GradeAutomatic

Voltage415 Volt (v)

Amey Shredtech Private Limited

Thane

18 Years

Super Premium

Super PremiumGas Re-Circulation Hydrogenators

Product DescriptionWe offer wide range of Process Reactors like Gas Re-Circulation Hydrogenators to meet diverse application ranging from Nitration, Ethoxylation, Reduction, Sulphonation, Fluorination, Bromination, Chlorination, Cyclization, Condensation, Amination, Phosgane Gas Reaction etc.\015\012Offered with proce

Dipesh Engineering Works

Mumbai

23 Years

Super Premium

Super PremiumCurd Separator - Automatic Grade: Semi-Automatic

Price: 100000 INR/Unit

MOQ01 Unit/Units

MaterialStainless Steel

ComputerizedNo

Automatic GradeSemi-Automatic

Capacity150 to 250 Kg/hr

Voltage240 Volt (v)

Frequency (MHz)50 Hertz (HZ)

Apollo Machinery

Ahmedabad

19 Years

Super Premium

Super PremiumCement Feeding System - Mild Steel, Dynamic Balancing for Smooth Operation | Heavy Duty Screw Type Pneumatic Pumps for Bulk Material Transfer

Product DescriptionWe are known Exporter, Manufacturer & Supplier of Cement Feeding System in Ahmedabad, Gujarat, India. This is the most versatile and speedy method of transferring bulk material from one point to another within a defined area.\015\012\015\012Applications\015\012The Air-Vac Equipment Screw Pumps are

Air Vac Equipment

Ahmedabad

18 Years

Continuous Mixer - Automatic Grade: Automatic

Price: 500000 INR/Piece

MOQ1 Piece/Pieces

MaterialSS

Capacity4 to 200 kW Kg/hr

ComputerizedYes

Automatic GradeAutomatic

Frequency (MHz)50/60Hz Hertz (HZ)

Luftsol Engineering Private Limited

Pune

2 Years

Rotary Drum Cleaner - Automatic Grade: Semi-Automatic

MOQ1 Unit/Units

TypeDrum cleaner

MaterialMild steel

ComputerizedNo

Automatic GradeSemi-Automatic

SizeStandard

WarrantyYes

Prominence Systems Pvt Ltd

Bhosari

Super Bonanza

Super Bonanza2 Years

Mulch Film Hole Punching Machine - Automatic Grade: Automatic

Price: 1851000 INR/Unit

MOQ1 Unit/Units

TypeOther

MaterialMild Steel

FeatureHeavy Duty Machine, Less Power Consumable

ComputerizedNo

Voltage220-440 Volt (v)

Frequency (MHz)50 Megahertz (MHZ)

Dnd Machinery Private Limited

Ahmedabad

4 Years

Super Premium

Super PremiumSemi-Automatic Micro Filtration Solid-Liquid Separator

Price: 5000000 INR/Set

MOQ1 Set/Sets

Typestandard

MaterialSS304, SS316

ComputerizedNo

Automatic GradeSemi-Automatic

Neotech Water Solutions

Vapi

9 Years

Roll Crusher - Heavy Steel Frame, Dual Alloyed Steel Rolls with Spring Loading Safety Feature | Optimal for Mineral Size Reduction

Product DescriptionThese Roll Crushers offered by us are utilized for added reduction in the sizes of minerals after excavation from the quarry, subjected to one or more stages of prior crushing. The construction includes a heavy steel frame integrated with two alloyed steel rolls, each heaped on separate horizontal

Moderate Machines (pvt.) Ltd.

Jaipur

14 Years

Semi-Automatic Jet Mixers

MOQ1 Unit/Units

TypeJet Mixers

MaterialStainless Steel

ComputerizedNo

Automatic GradeSemi-Automatic

Voltage110-220 Volt (v)

Warranty1 Year

Sahyadri Engineering Corporation

Mumbai

3 Years

Double Cone Blender - Stainless Steel Construction, Automatic Operation | High Tensile Strength, Low Power Consumption, Versatile Usage

Price: 1200000.00 INR/Set

MOQ1 Set/Sets

TypeDouble Cone Blender

Product TypeDouble Cone Blender

General UseIndustrial

MaterialStainless Steel

ComputerizedNo

Automatic GradeAutomatic

B. R. Industries

Hyderabad

15 Years

Bar Straightening Machine / Scrap Straightening Machine - Automatic Grade: Semi-Automatic

Price: 311700 INR/Piece

MOQ1 Piece/Pieces

TypeOrange Bar Straightening Machine / Scrap Straightening Machine

MaterialStainless Steel

ComputerizedNo

Automatic GradeSemi-Automatic

Voltage220 Volt (v)

SizeStandard

Orange Construction Equipment

Palghar

2 Years

Groundnut Processing Plant - Automatic Grade: Automatic

Price: 5123000 INR/Unit

MOQ1 Unit/Units

TypeGroundnut Processing Plant

MaterialMetal

Capacity4 Ton/day

ComputerizedNo

Automatic GradeAutomatic

Voltage415 Volt (v)

Tulsi Agro Engi Mech Pvt. Ltd.

Rajkot

12 Years

Cooling Blender - Automatic Grade: Automatic

Price: 150000 INR/Unit

MOQ1 Unit/Units

TypeBlending and Mixing Machines

ComputerizedYes

Automatic GradeAutomatic

Voltage240 Volt (v)

WarrantyYes

Fans Bro Erectors

Vasai

19 Years

Glass Bottle Washing Machine - Automatic Grade: Semi-Automatic

Price: 17000.0 INR/Unit

MOQ1 Unit/Units

MaterialStainless Steel

ComputerizedNo

Automatic GradeSemi-Automatic

SizeCustomized

WarrantyYes

Sri Guru Industries

Coimbatore

3 Years

Patson Machines Pvt. Ltd.

Pune

16 Years

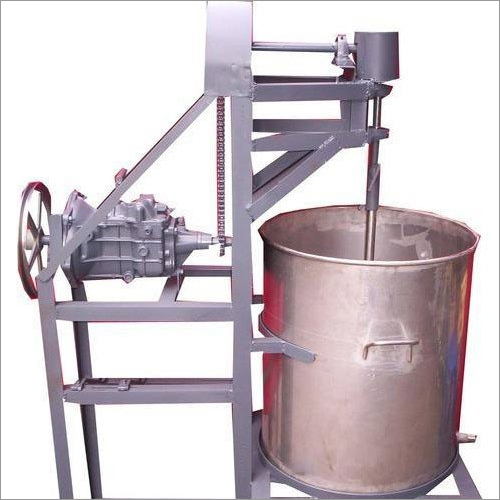

Automatic Liquid Mixer Machine

Price: 75000 INR/Piece

MOQ1 Piece/Pieces

TypeLiquid Mixer Machine

MaterialStainless Steel

Automatic GradeAutomatic

Frequency (MHz)50 Hertz (HZ)

Innovative Engineering Works

Ahmedabad

Super Bonanza

Super Bonanza4 Years

Super Premium

Super PremiumLatest From Processing Machines & Equipment

Heavy Duty Single Drum Conical Mixer

By:

Swastik Industries

CTB Wet Drum Magnetic Separator

By:

Maanshan Baiyun Environment Protection Equipment Co., Ltd.

SUB Series Gate Operators

By:

Maple Leaf Electrovacs & Access Systems Pvt. Ltd.

Tarpal Plant

By:

Mohan Mechanical Works

Vat For Ghee, Cheese, Butter and Paneer

By:

Bliss Engineering

Neutralizer Tank

By:

Rahul Expeller Industries

Dispersion Kneader

By:

Amgm Manufacturing Pvt. Ltd.

Anchor Agitator

By:

Kalina Engineering Pvt. Ltd.

Mixing Tanks

By:

Neela Systems Ltd.

Ribbon Mixers

By:

Paresh Engineering Co.

Explore More Cities

Ready To Ship Processing Machines & Equipment

What Are Processing Machines?

Bill Gates has said, "The advance of technology is based on making it fit in so that you don't really even notice it, so it's part of everyday life." Product processing machines, serving as the vanguards of industrial innovation, epitomize the transformative power that turns raw materials into high-quality, refined products characterized by unparalleled quality and precision rate. Their utilization, both in small-scale enterprises and large industrial operations, has undeniably reshaped the landscape of manufacturing and enriched the ever-evolving tapestry of human creativity. These mechanical marvels, adorned with state-of-the-art technology and exemplary craftsmanship, harness the potential of automation to conduct an intricate symphony of complex procedures. With their coveted position in the realms of manufacturing facilities and scientific laboratories, product processing machines infuse vitality into the aspirations of inventors, engineers, and artisans, transcending boundaries and unlocking new possibilities for human progress.

Types of Processing Machine

There are numerous types of processing machines that are abundantly demanded in the market and are of paramount importance in commercial and industrial applications. Let's examine these kinds of machines.

Food processing machines are premium stalwarts, symbolizing the pinnacle of technological prowess and culinary improvement. These innovative devices harmonize the art and science of food preparation with a plethora of specialized devices, such as blenders, mixers, grinders, and slicers, each catering to different culinary demands. Food processing machines revolutionize the way we perceive, create, and savor culinary pleasures by mechanizing complicated jobs, optimizing manufacturing processes, and protecting the integrity of ingredients.

The significance and need for road construction machinery resonate across the infrastructure development environment, enabling global progress and connectivity. These machines have a significant impact, functioning as essential tools in the building, maintenance, and upgrading of road networks. With increasing urbanization and transportation requirements, the need for strong and efficient road-building machinery has skyrocketed.

The significance and demand for roll mill machines are recognized across a wide range of sectors where accuracy and consistency in material processing are critical. Metalworking, chemical engineering, pharmaceuticals, and food processing are just a few industries that use these flexible devices. Roll mill machines serve an important role in processing raw materials into polished products, allowing for the precise fabrication of varied forms, shapes, and textures. Their precision control over variables like temperature, pressure, and speed provides reliable and homogeneous outcomes.

Categories of Processing Machines

Product processing machines are categorized based on their ability to meet the specific requirements of diverse industries and applications. These machines play a crucial role in efficiently and precisely transforming raw materials into finished products. Some notable categories include:

- Cutting and Machining Machines: These machines, such as lathes, milling machines, and laser cutters, excel in shaping and fabricating materials by removing excess material through cutting, drilling, or shaping processes. They find extensive use in industries like metalworking, woodworking, and plastics.

- Molding and Forming Machines: This category encompasses machines like injection molders, press machines, and extruders that shape materials into desired forms and structures. Industries such as plastic molding, metal forming, and ceramics heavily rely on these machines.

- Mixing and Blending Machines: These machines, including blenders, mixers, and homogenizers, are adept at combining different ingredients or materials into a homogeneous mixture. They are vital across industries like food processing, pharmaceuticals, and chemical manufacturing.

- Heating and Cooling Machines: These machines enable precise temperature control and thermal processes during material processing. Industries engaged in heat treatment, baking, and refrigeration benefit from these machines.

- Packaging and Labeling Machines: This category encompasses filling machines, sealing machines, and labeling machines that automate the packaging and labeling processes for finished products. Industries like food and beverage, pharmaceuticals, and consumer goods rely on these machines for efficient packaging operations.

These categories cover a wide range of processing equipment that may be found throughout several businesses and fields. Each category includes unique machines that are created to carry out certain duties and operations.

Applications of Processing Machines

Product processing machines find wide-ranging applications in numerous industries, enabling efficient and precise production processes. Let us explore the primary uses of these machines in various sectors where they play a vital role in enhancing output.

- Food and Beverage Industry: Product processing machines are integral to food and beverage production, performing tasks such as cutting, mixing, blending, cooking, cooling, and packaging. Machines like mixers, ovens, filling machines, and labeling equipment are indispensable for manufacturing a diverse range of food and beverage products.

- Chemical Industry: In the chemical industry, product processing machines are extensively used for mixing, blending, reacting, and transforming raw materials into chemical products. Machines such as reactors, mixers, centrifuges, distillation columns, and drying equipment are essential for chemical manufacturing processes.

- Construction Industry: Product processing machinery, including concrete mixers and crushers, plays a critical role in the construction sector. These machines facilitate the mixing, crushing, and placement of construction materials, contributing to the construction of buildings, roads, bridges, and other infrastructure projects.

Top Processing Machines Manufacturers in India

The digital revolution is powered by processing machines, which advance innovation and progress. Here is a list of top processing machine manufacturers in India.

• ECOMAN is a popular manufacturing company located in Vadodara, that is engaged in the making of a processing device known as a vibrating feeder.

• Siddharth Engineering Co. is another manufacturer of processing equipment which is based in the Navi Mumbai region with an experience of about 22 years.

• JSN ENTERPRISE is a Vadodara-based enterprise that has an experience in the sector for 13 years.

• With 16 years of expertise, Ahmedabad-based AIR VAC EQUIPMENT produces cement feeding systems.

FAQs: Processing Machine

Q. Why are processing machines important in production industries?

Ans. Product processing machines play a critical role in the landscape of manufacturing sectors, acting as crucial catalysts that accelerate efficiency, accuracy, and scalability to unparalleled heights. These complex wonders represent the pinnacle of technical prowess, providing unrivaled capabilities to production operations. They manage activities with careful precision, reducing human error and shortening production cycles through the seamless integration of technology.

Product processing machines optimize resource utilization, reduce waste creation, and raise product quality to unrivaled levels by utilizing cutting-edge technology such as robotics, artificial intelligence, and smart sensors. Their unshakable consistency, steady throughput, and excellent reproducibility make them crucial cornerstones of industrial innovation, amplifying productivity and driving manufacturing industries to the pinnacle of success.

Last but not least, processing equipment acts as a safety guard, reducing possible hazards and preserving human welfare. Such a piece of machinery fosters a safer working environment and instills a sense of security by protecting human operators from risky jobs.

Q. What kind of processing machines are used in the food industry?

Ans. "Processing machines are the allies of human ingenuity, augmenting our capabilities and expanding the boundaries of what we can achieve."

The food industry employs a diverse range of processing machines to handle various tasks involved in food production, processing, and packaging. Here are some common types of processing machines used in the food industry:

Mixing and Blending Machines: Equipment used in the food business to effectively combine, mix, and blend materials includes food mixing and blending machines. While providing reliable and uniform output, these devices also save time and labor.

Grinding and Pulverizing Machines: In many sectors, including food processing, medicines, chemicals, and agriculture, grinding and pulverizing equipment is crucial. These devices are used to reduce solid materials to powders or smaller pieces.

Hammer mills: Food processing hammer mills are specialized equipment used in the food business to quickly and effectively grind and pulverize a variety of substances into powders or smaller pieces. These mills are frequently used in food processing facilities for jobs like grinding spices, grains, herbs, and other materials. They are made to handle a variety of food items.

Pulverizers: Machines used in the food business to grind, pulverize, and reduce different food components into small powders or particles are called food processing pulverizers.

Packaging Machines: Machines designed specifically for the food sector are used to effectively package and seal food goods. These devices are essential for maintaining the quality, safety, and freshness of food while assuring effective and hygienic packaging procedures.

Sealing machines: To make airtight seals on various types of packing containers, the food industry uses specialized equipment known as food processing sealing machines.

Sterilization and pasteurization machines: Machines used in the food industry to sterilize and pasteurize food are essential for ensuring food safety by removing or decreasing hazardous germs.

Market and demand for processing equipment

Processing machines may indeed be a very long-lasting investment for certain enterprises. As companies work to lessen their environmental effect and adopt more eco-friendly practices, sustainability has emerged as a primary priority in a number of industries, including the food industry. Purchasing environmentally friendly industrial equipment has various advantages.

Manufacturers & Suppliers of Processing Machines & Equipment

Company Name | Member Since |

|---|---|

Siddharth Engineering Co. Navi Mumbai, India | 24 Years |

Dipesh Engineering Works Mumbai, India | 23 Years |

Chemech Engineering Mumbai, India | 21 Years |

Advanced Drying Systems Vasai, India | 20 Years |

Apollo Machinery Ahmedabad, India | 19 Years |

Fans Bro Erectors Vasai, India | 19 Years |

Miranda Automation Pvt. Ltd. Navi Mumbai, India | 18 Years |

Amey Shredtech Private Limited Thane, India | 18 Years |

Air Vac Equipment Ahmedabad, India | 18 Years |

Patson Machines Pvt. Ltd. Pune, India | 16 Years |

Popular Products