Water Jet Cutting Machine

(160 products)Rotary Screen Stripping Machine

Price: 7000000 INR/Unit

MOQ01 Unit/Units

Payment TermsCash Advance (CA), Cash in Advance (CID), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T)

Supply Ability02 Per Month

Delivery Time7 Days

A Innovative International Ltd.

Ahmedabad

STREAMLINE SL-VI 15 High Pressure Pump - 4136 bar

MOQ1 Unit/Units

Main Domestic MarketAll India

Shape Waterjet Private Limited

Mumbai

Desktop Mini Cnc Waterjet Cutting Machine For Industrial - Material: Metal

Price: 1575000 INR/Unit

MOQ1 Unit/Units

MaterialMetal

Voltage220-440 Volt (v)

Power SupplyElectric

Size400*500 mm Floor Space Size

WarrantyYes

Industrial Water Jet Cutting Machine - Material: Stainless Steel

MOQ1 Unit/Units

MaterialStainless steel

Voltage220-440 Volt (v)

Power SupplyElectric

SizeStandard

WarrantyAvailable

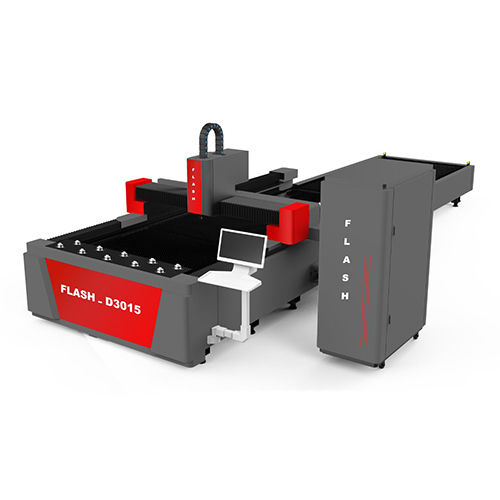

Stainless Steel Flash-D3015 Fiber Laser Cutting Machine

Price: 2000000 INR/Set

MOQ1 Set/Sets

Product TypeCNC Water Jet Cutting Machine

MaterialStainless Steel

Power SupplyElectric

SizeCustomized

WarrantyYes

Ss Industrial Cnc Waterjet Cutting Machine

MOQ1 Unit/Units

Product TypeOther, CNC Waterjet Cutting Machine

MaterialSS

Voltage240 Volt (v)

SizeStandard

WarrantyYes

Arnavi Machines Private Limited

Bengaluru

CNC Water Jet Cutting Machine - 3015 Model, 3000x1500mm Working Area | 50 HP Pump Power for Precision Stone, Metal, and Steel Cutting

Product DescriptionRunning with wide business growth verticals, we at "R K CORPORATION" are engaged as manufacturer and supplier of CNC Water Jet Cutting Machines in Ludhiana, Punjab, India.\015\012\015\012Specifications:\015\012Model no 3015\015\012working area 3000x1500mm\015\012pump power 50 HP\015\012use for stone

Ss Automatic Water Jet Cutting Machine

Price: 3000000 INR/Unit

MOQ01 Unit/Units

Product TypeOther, Water Jet Cutting Machine

MaterialSS, MS

Power Supplyelectric

SizeStandard

Warranty01 Year

Cnc Water Jet Cutting Machines With 1 Year Of Warranty Motor Power: 37 Kilowatt (Kw)

Price: 4500000 INR/Set

MOQ1 Set/Sets

Product TypeCNC Water Jet Cutting Machine

Power Supply3 Phase

Motor Power37 Kilowatt (kW)

Pressure450 mpa

Warranty1 Year

Stainless Steel Co2 Jet Machine

Price: 13000 INR/Unit

MOQ10 Unit/Units

MaterialStainless Steel

Power SupplyElectricity

SizeDifferent Available

Ultra High Pressure Water Jetting

Product DescriptionOur organization is among the acclaimed names in the industry for manufacturing and supplying a wide range of Ultra High Pressure Water Jetting in Hyderabad, Telangana, India. We offer a wide range High and Ultra High Pressure (UHP), positive displacement plunger pumps and water jetting equipment fo

Airblast Equipment India Private Limited

Hyderabad

CNC Water Jet Cutting Machine - Versatile Material Compatibility for Precision Cutting | Ideal for Glass, Marble, Granite, Foam, Acrylic, Ceramics, Tiles, and Stainless Steel

Product DescriptionUSES : * CORINA CUTTING. * GLASS CUTTING. * FOAM CUTTING. * MARBLE CUTTING. * GRANITE CUTTING. * PLASTICS CUTTING. * ACRYLIC CUTTING. * CERAMIC CUTTING. * TILES CUTTING. * STAINLESS STEEL CUTTING

Large Capacity Waterjet Abrasive Cutting Machine

Payment TermsCash Against Delivery (CAD)

Main Domestic MarketAll India

Trim Cutter - Brass With Ceramic Core, 140 Bar High Pressure Precision Trim Nozzle for Clean Cuts

Product Description\015\012Trim cutter\015\012\015\012Basic Type\015\0121. CN38170: Brass With ceramic core\015\0122. CN38171: Needle header and CY38172 strainer\015\0123. RBY: Needle ruby core\015\0124. CER: Ceramic core\015\012\015\012This kind of nozzle used for trimming of the paper that supply a precise ,clean cu

Gmt Water Jet Cutting Machine

Product DescriptionSince its inception our company has been involved in trading and supplying a supreme great quality Water Jet Cutting Machine by being established in Chennai, Tamil Nadu, India to be able to fulfill different needs of the customers. The Water Jet Cutting Machine offered by us is popular among our cus

Cnc Water Jet Cutting Machine Capacity: 3*2 Meter Milliliter (Ml)

Price Trend: 29999-35999 USD USD ($)/Set

MOQ1 Set/Sets

Product TypeCNC Water Jet Cutting Machine

Materialsteel

Capacity3*2 meter Milliliter (mL)

Power Supply30KW

Motor Power30 Kilowatt (kW)

Cutting Accuracy0.1 mm

Foshan Baotao Machinery & Equipment Co., Ltd.

Foshan

Hydraulic Solenoid Valves - Premium Quality Materials, Rugged Design & Fine Finish

Payment TermsPaypal, Others, Western Union, Telegraphic Transfer (T/T)

Delivery Time1 Week

Sample PolicyContact us for information regarding our sample policy

Heavy Duty Waterjet Cutting Machine Size: Standard

Product TypeMetal Water Jet Cutting Machine

Power SupplyElectricity

SizeStandard

Intensifier Waterjet Cutting Pump

Product DescriptionWith the consistent focus on our quality, we are presenting to our clients a huge range of superb quality Intensifier Waterjet Cutting Pump, which is highly appreciated for their high performance and longer service life. A superior quality material and modern technology is used in manufacturing thes

CNC Water Jet Cutting Machine - Heavy Duty Stainless Steel, 24/7 Operation | High Accuracy with Ball Screws and LM Guiding System

Product DescriptionWater Jet Germany Private Limited manufactures complete CNC Water Jet cutting machines, which are highly productive with low downtime and can work continuously - 24 hours a day. Water jet Germany Private Limited uses heavy duty steel frame system for the machine Gantry and the tank is made with high

PRASAD Water Jet Cutting Machine

Product DescriptionWater Jet Cutting Machines Can Be Used for Cutting Any Profiles with Accuracy. Various Kinds of Metals Ferrous and Non-ferrous such as Steel, M.s, Brass, Copper, Alloys, Stone, Compounds and Glass Etc. Can Be Profiled

CNC Water Jet Cutting Machine - Premium Flow Quality Table with KMT Pump | Cost-Effective Precision Cutting Solution

Product DescriptionOur customers can avail from us an excellent quality range of CNC Water Jet Cutting Machines. Flow quality table + genuine KMT pump==First quality water jet cutting machine, but affordable price.\015\012\015\012Our engineers once made the water jet cutting tables for Flow and the cutting tables powe

Cmt Cutting Machine Tools (shanghai) Co., Ltd.

Shanghai

Metal Cnc Under Water Cutting Machine

Product TypeCNC Water Jet Cutting Machine

MaterialMetal

Voltage220AC Volt (v)

SizeStandard Size Available

Jiangsu Oupu Cutting & Welding Machine Co., Ltd.

Taixing

CNC Water Jet Cutting Machine - 50,000 psi Pressure, 20 m/min Speed | Gantry Type, Motorized Z Axis, Low Maintenance, OMAX Software

Payment TermsCash Against Delivery (CAD), Cash in Advance (CID), Cheque

Sample PolicyContact us for information regarding our sample policy

Main Export Market(s)Asia

1500*2500Mm 420Mpa Abrasive Water Jet Cutting Machine Capacity: 100% T/Hr

Price: 30000 USD ($)/Set

MOQ1 set Set/Sets

Product TypeCNC Water Jet Cutting Machine

Materialcan cut nearly all materials

Capacity100% T/hr

Voltage380 Siemens Volt (S )

Power Supply37kw

Motor Power37 Kilowatt (kW)

Shandong Wami Cnc Technology Co., Ltd

Jinan

White Cnc Water Jet Cutting Machine

Payment TermsPaypal, Others, Western Union, Telegraphic Transfer (T/T)

Delivery Time1 Week

Sample PolicyContact us for information regarding our sample policy

CNC Water Jet Cutting Machine - High Pressure Water Jet System | Automatic Abrasive Discharge Unit, Quicker Cutting with Fine Finishing, Automatic Water Cooling Cycle, Excellent Pump Pressure

Product DescriptionWe are manufacturer and suppliers a wide range of CNC Water Jet Cutting Machine in Rajkot, Gujarat. We have well experience workers and engineers are available to develop latest design of CNC Water Jet Cutting Machine with availability of every certification which we will give you more satisfaction

Latest From Water Jet Cutting Machine

Industrial Water Jet Cutting Machine

By:

Techno Laser Industries

High Performance Long Lasting Mild Steel Automatic Cnc Water Jet Cutting Machine

4800000 INR

By:

A Innovative International Ltd.

Servo Direct Drive Pump Water Jet Cutting Machine 420Mpa 60000Psi

46800 USD ($)

By:

Shandong Wamit Cnc Technology Co., Ltd

CNC Water Jet Cutting Machine

29999-35999 USD USD ($)

By:

Foshan Baotao Machinery & Equipment Co., Ltd.

Cnc Water Jet Cutting Machine

By:

M.d. Corporation

M J Water Jet Cutting Machine

By:

M J Trading

Best High Pressure Water Jet Cutting Machine

By:

Shape Waterjet Private Limited.

1500*2500mm 420mpa Abrasive Water Jet Cutting Machine

30000 USD ($)

By:

Channel Ark Technology Development Limited

Explore More Cities

Ready To Ship Water Jet Cutting Machine

Water Jet Cutting Machine Introduction

In the industrial process known as "water jet cutting," several kinds of materials are cut and shaped using high-pressure water jets delivered by pressurizing pumps that produce a supersonic stream of water. In water jet cutting, a tiny, precise nozzle is used to project water that has been pressured to 392 MPa. Three times the speed of sound is reached by the water as it exits the nozzle. Water serves as the cutting medium in pure water jet cutting, which is intended for soft materials like rubber, wood, and plastic. Cutting becomes more aggressive and is capable of cutting hard metals when an abrasive is added to the water stream, such as concrete, glass, aluminum, stainless steel, ceramic material, and titanium.

Types of Water Jet Cutting Machine

The water jet cutting process is coupled to a sizable controlling mechanism that includes an X-Y movement system, catch tank, controller, and a high-pressure pump, a pure water or abrasive nozzle in water jet cutting machines. Motion control, which serves the dual purposes of regulating the cutter's motion and offering a means of keeping the workpiece in place, is an essential part of a water jet cutting machine. The procedures utilized to create water jet cutting machines come in a variety of sorts, sizes, shapes, and designs. Many of the various types feature CNC controls, which improve the cutting process' accuracy.

Computer Numerical Control (CNC): The CNC machine, which can be programmed to carry out several operations on a workpiece in one pass, is a highly ubiquitous component of contemporary production. Since many years ago, water jet cutting has been routinely performed using CNC programming, which combines the best cutting technology with exact control. All of the attributes and features of water jet cutting are included in a CNC water jet cutting machine. Flatbed machines with CNC programming attached to the machine's parts are often used for CNC water jet cutting. With its adaptability and versatility, CNC water jet cutting machines may be tailored to any manufacturing demand.

Flatbed Water Jet Cutting Machines: These include a working table that enables for the cutting of huge items. The flatbed design makes it simple to load and unload things from the table. The capacity of these machines to collect waste materials and water from the cutting process is one of its key features. Flatbed water jet cutting machines are popular due to their inexpensive cost, versatility in cutting materials, and lack of heat. Parts for water jet cutting retain their heat treatment while being cut, eliminating the need for further heat treatment after the fact.

Portable Water Jet Cutting: For eliminating burrs, cutting off rust, and cleaning polluted surfaces, this type of machine provides a low-cost, ecologically friendly, and adaptable cutting technique. They are appropriate for usages in risky and hazardous environments, such as the pipeline and oil industries. These types of devices are able to go through any kind of material and have all the advantages of velocity and high-pressure water. How the abrasive is introduced into the water stream distinguishes the two main kinds of portable water jet cutting machines. One approach is to provide the abrasive while it is being discharged via the nozzle. The second, less successful method involves mixing the abrasive with the water before applying pressure.

What is Water Jet Cutting?

The basic principles of water jet cutting are velocity, abrasive, and pressure. Although the procedure is not difficult, there are many different ways it may be used. Several versions have been created to precisely match the requirements for various applications. Pure water and pure water with an abrasive are the two categories of water jet cutting. The procedure is further segmented based on a number of criteria after these two divisions into:

- High-Pressure Water Cutting

- CNC Water Jet Cutting

- Abrasive Jet Machining

- Abrasive Flow Machining (AFM)

Waterjet Cutting Machine Features

The features of a water jet cutting machine are:

- Extreme accuracy

- It is hygienic

- Product Management

- Secondary Finishing

- Efficiency of Water Jet Cutting

- Cutting using a water jet may save money.

- Effortless Use

- Chemicals are absent

- Versatility Advantage

- Ecologically sound

- Shape programming.

Waterjet Cutting Machine Uses

The uses of water jet cutting machines in different industries are:

Aerospace Industry Water Jet Cutting: Complex and precise accuracy is required for all aircraft components. The rules of aerospace prohibit any kind of mistake. Water jet cutting is a crucial component in the manufacture of aerospace parts, from the construction of jet engines to the creation of bespoke control panels, for just this one reason.

Medical Water Jet Cutting: Surgical cutting instruments are being replaced in medicine by water jet cutting technology. When treating malignancies, high-pressure spiral water smashes and pulls liver parenchymal cells. It is chosen to carry out these tasks because it reduces the possibility of bleeding and does not emit heat that might harm other organs. Human tissue may be dissected with less stress, bleeding, and postoperative issues by varying the flow rate and pressure.

Vehicle Industry: The ability of water jet cutting to be incorporated into robotic systems is a crucial aspect of its utilization in the car sector. Pure water jet cutting is used to form head linings, indoor carpets, and insulation. Both water jet cutting techniques are used. Pure water jet cutting causes the elimination of clean-up and low material waste.

Industrial Cleaning using Water Jet Cutting: During the course of many industrial operations, undesirable materials are produced. Additionally, owing to the build-up of rust, scales, and flakes, industrial conduits, and storage tanks need to be cleaned. Although extremely corrosive cleansers may remove built-up debris, they might not be appropriate in all situations. Industrial machinery, storage containers, and pipes may be safely removed and cleaned using a high-pressure water jet cutting device's high-speed, pulsing blast.

Food Industry cutting: A technique of cutting food that has been recognized by the USDA offers productivity and hygienic advantages is water jet cutting. The food sector relies on water jet cutting for its accuracy and helps with portion control, much like other industrial applications for it. Frozen goods, pastries, poultry, fish, and Meat may all be expertly and precisely shaped with a water jet cutter.

Cutting of Glass: Water jet cutting of glass is employed because the cutting stream may be modified, adjusted, and changed, much as in the medical industry. Glass cutting is an extremely delicate technique that calls for precise instruments to prevent shattering or puncturing the glass. Smooth and effective cutting is made possible by water jet cutting's capacity to cut glass without harming the material's internal structure. Any shape, form, arrangement, or workpiece may be precisely sliced using the omnidirectional stream. The stream's precise precision and tremendous pressure enable it to carve structures without distortion, holes, and notches.

Water Jet Fiberglass Cutting: The main concern while handling fiberglass is safety, which calls for accuracy, efficiency, and precision. Fiberglass may be shaped and formed by water jet cutting without producing dust or waste. Quick cuts are created to the application's exact measurements.

Water Jet Cutting Electronics: Cost is a significant problem in the manufacture of electronics. Manufacturers are always looking for methods to cut costs while boosting productivity. Water jet cutting has become an important component in the fabrication of electronics due to its efficiency and cost-effectiveness. Circuit boards may be sliced using this method whether they are filled with components or not. Additionally, it works well for stripping wires without having to worry about doing any harm to the wire.

FAQs: Water Jet Cutting Machine

Question: How does the water jet cutting machine work?

Answer: Simply said, a material's internal degradation is increased during the waterjet cutting process. A mixing chamber is filled with highly pressurized water that is shot via a ruby or diamond nozzle. The vacuum produced by the pressure pulls garnet sand into the stream, where it is discharged towards the target to be cut.

Question: How type of metal can a water jet machine cut?

Answer: Prominent metal fabricators use waterjet machines because they can readily cut any metals, including hardened tool steel, aluminum, titanium, copper, brass, and other exotic metals.

Question: What is the difference between laser cutting & water jet cutting machines?

Answer: More inches per minute are cut by laser cutting than by waterjet cutting on average.

Manufacturers & Suppliers of Water Jet Cutting Machine

Company Name | Member Since |

|---|---|

Markwel Equipments Private Limited Delhi, India | 18 Years |

A Innovative International Ltd. Ahmedabad, India | 17 Years |

R K Corporation Greater Noida, India | 15 Years |

Techno Laser Ahmedabad, India | 4 Years |

Shape Waterjet Private Limited Mumbai, India | 3 Years |

Cad Mech Engineering Pvt Ltd Pune, India | 2 Years |

Arnavi Machines Private Limited Bengaluru, India | 2 Years |

Popular Products