Flanges

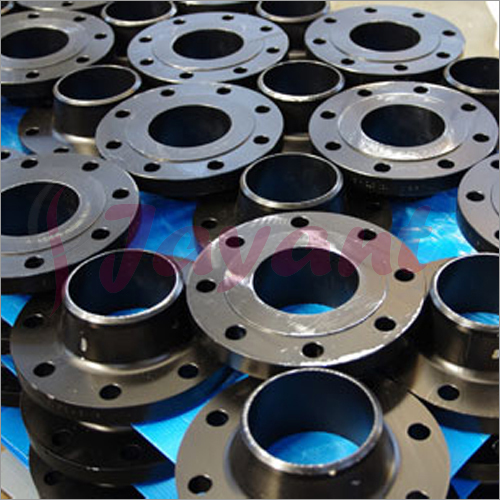

(13141 products)Round Steel Flanges

1000 INR (Approx.)/Piece

MOQ1 , Piece/Pieces

Product TypeFlanges, Other

MaterialSteel

ShapeRound

SurfaceOther

SizeDifferent Available

Red Wheel Flanges

Price: 1000 INR/Piece

MOQ1000 Piece/Pieces

ColorRed

Product TypePipe Flanges

Spectacle Flanges - Application: Industrial

MOQ1 Piece/Pieces

ApplicationPipe and valve connections

FeatureHigh durability and easy installation

GradeIndustrial quality

Dimension (L*W*H)Customizable dimensions

Product TypeSpectacle Flanges, Other

MaterialStainless steel

Silver Reducer Flange End

Price: 30000 INR/Number

MOQ50000 Unit/Units

GradeCarbon Steel

ColorSilver

Dimension (L*W*H)711mm X 245mm Millimeter (mm)

Product TypeSlip On Flanges

MaterialSS 316

StandardDIN

Ss Flange - Application: Industrial

Price: 100 INR/Number

MOQ10 Number

ApplicationIndustrial

Product NameStainless Steel Products

MaterialStainless Steel

Steel TypeStainless Steel

StandardOther, ASTM

Steel Product TypeOther

Equalizing Valve Oval Flange

Product DescriptionWe are perceived as a presumed association occupied with Exporter, Importer, Manufacturer, Service Provider, Distributor, Supplier, Trading Company a broadly demanded array of Equalizing Valve Oval Flange in Ahmedabad, Gujarat, India. These are offered by us fabricated as per the standards and princ

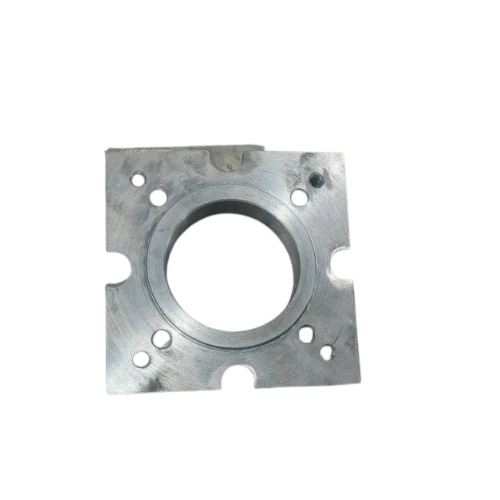

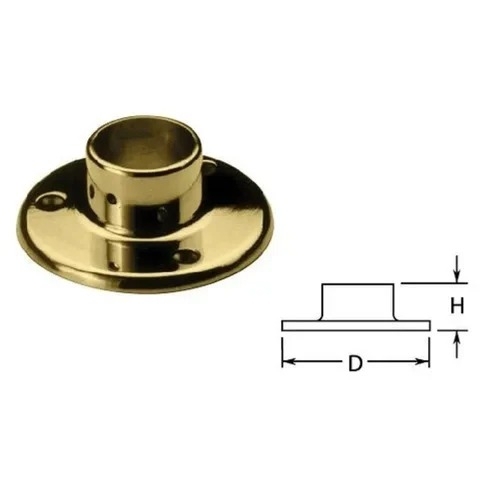

Flange- Square Application: Fitting Purpose

Price: 112 INR/Piece

MOQ10 , Piece/Pieces

ApplicationFitting Purpose

MaterialBrass

ShapeSquare

SurfaceOther

Size1-5 Inch

ColorSilver

Aim Tech

Jalandhar

Super Premium

Super Premium17 Years

Super Premium

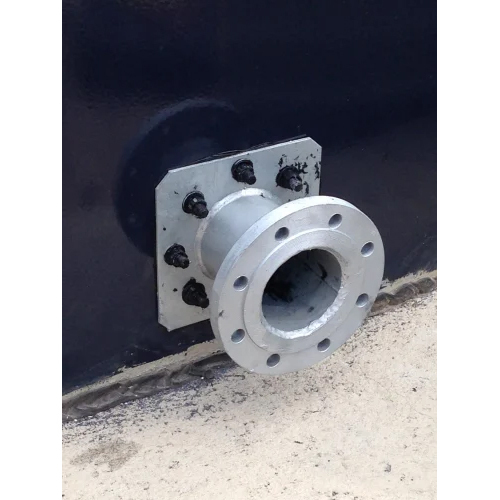

Super PremiumDuctile Iron Flange - 3", 4", 6", 8", 10", 12" OD Sizes | ASTM A536, 250 PSI, Male Connection, Black Finish

Price: 1400 USD ($)/Ton

MOQ10 Ton/Tons

ApplicationDuctile Iron Flange for Ductile Iron Pipes with OD Size - 3" dia, 4" dia, 6" dia, 8" dia, 10" dia, 12" dia

Dimension (L*W*H)DI Pipes with OD Size - 3" dia, 4" dia, 6" dia, 8" dia, 10" dia, 12" dia Inch (in)

Product TypeThreaded Flanges

MaterialDuctile Iron Flange as per ASTM A536

StandardANSI

ShapeRound

Yellow Base Flange

Price: 450 INR/Piece

MOQ50 Piece/Pieces

SurfaceGalvanized

ConnectionMale

ColorYellow

Cupro Nickel Flanges Application: Industrial

Price: 10000 INR/Piece

MOQ100 Piece/Pieces

ApplicationIndustrial

Sliver Alloy Flanges

MOQ10 Piece/Pieces

GradeIndustrial

Product TypeOther, Alloy Flanges

MaterialAlloy Steel

ShapeRound

ColorSliver

IBR Flanges - High-Strength Steel, Durable Design for Industrial Applications, Corrosion-Resistant Features

Price: 340 INR/Piece

MOQ1 Unit/Units

Supply Ability10 Per Week

Delivery Time1 Days

SS Flanges - Stainless Steel, Round Shape | ANSI Standard, Galvanized Surface

Price: 220 INR/Kilograms

MOQ100 Kilograms/Kilograms

MaterialStainless Steel

StandardANSI

ShapeRound

SurfaceGalvanized

GI Flange - High-Quality Galvanized Iron, Standard Size 4 inches, Durable Performance and Corrosion Resistance

Price Trend: 200.00 - 300.00 INR/Piece

MOQ100 , Piece/Pieces

Supply Ability50 Per Week

Delivery Time5-7 Days

Unique Malleables

Jalandhar

Trusted Seller

Trusted Seller7 Years

Stainless And Duplex Steel Flanges - Customized Size, Silver Color | High Purity 99.99% SS Material, ASTM Standard, Excellent Quality

Price: 300 INR/Piece

MOQ1 Piece/Pieces

Purity99.99%

FeatureGood quality

Product TypeOther, Duplex Flanges

MaterialSS

StandardASTM, Other

ShapeRound

Stainless Steel Din Flange - Round Shape with Galvanized Surface, Ideal for Oil and Gas Industry, Non-Combustible and Corrosion-Resistant

Price: 450 INR/Piece

MOQ135 Piece/Pieces

ApplicationOil and Gas Industry

GradeNa

PurityNa

FeatureNa

Dimension (L*W*H). Inch (in)

Product TypeOther

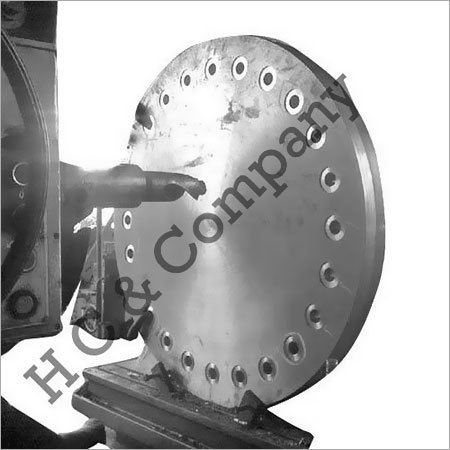

Orifice Plates And Flange Assemblies

Product DescriptionWe are manufacturing, exporting and supplying a range of Orifice Flange Assemblies in Ankleshwar, Gujarat, India, which are available in various sizes, shapes dimensions. These are designed as per BS standards 1042 part 1964 on is standards. These are manufactured by utilizing premium quality raw ma

Fidicon Devices India Private Limited

Ankleshwar

Carbon Steel Lap Joint Flange 65 - 150-2500 LBS Rated, Round Shape | Corrosion Resistant, Rust Proof, Accurate Dimensions, High Pressure & Temperature Load

Price Trend: 350.00 - 350.00 INR/Kilograms

MOQ500 Kilograms/Kilograms

ApplicationPaper & Pulp Companies, High Pressure Applications, Oil and Gas Industry, Chemical Refinery And Pipeline

FeatureCorrosion resistant, Accurate dimensions, Can sustain high pressure & temperature load And Rust proof

Purity98%

Product TypeOther, Joint Flange

MaterialCarbon Steel

StandardASTM A105 To ASTM A182, Other

Wnrf Flange - Color: Silver

Price: 2500 INR/Piece

MOQ5 , Piece/Pieces

ColorSilver

Product TypeOther

MaterialA105

SS Flanges - Stainless Steel, Multiple Types Including Weld Neck, Blind, and Slip On, Hard to Find Selection

Product DescriptionOwing to the existence of our experienced and knowledgeable team members we are capable to manufacture a wide range of SS Flanges. These SS Flanges are obtainable in the industry are in several shapes such as lapped, screwed, spectacle, weld neck, blind, slip on boss, reducing, plate, plate blank,

SS Flanges - Premium Quality Stainless Steel | Durable, High-Performance, Precision-Fabricated Flanges

Product DescriptionWe are among the most preferred organizations active in the business of exporting, importing and supplying a huge array of SS Flanges from Mumbai, Maharashtra, India. The offered SS Flanges are obtained from the vendors who fabricate it using the high quality raw material and latest technology. Thes

Plastic Pp Hose Nipple Flanges Application: Structure Pipe

Price: 200 INR/Piece

ApplicationStructure Pipe

Product TypePipe Flanges

MaterialPolypropylene

SizeAs Per Order Or Availability

ColorGray

Brothers Plast Tech Private Limited

Ahmedabad

Easy to Use Hot And Cold Pack

Price: 84.50 INR/Piece

MOQ100 Piece/Pieces

Product TypeHot and Cold Pack, Other

Size20 x 12 cm

ColorBlue, Red

Industrial Flanges - High-Grade Raw Material, Durable Design | Flawless Finish, Precise Construction, High Tensile Strength

Product DescriptionWe are a coveted firm engaged in manufacturing and supplying a wide range of Industrial Flanges. Our offered products are designed and manufactured using high-grade raw material and latest technology machines. It is highly used due to their features such as durability, precise construction, flawless

Stainless Steel Flanges Application: For Construction

Price: 350 INR/Kilograms

MOQ1 Kilograms/Kilograms

Purity98%

GradeTP304

ApplicationFor Construction

Product TypeSteel Flanges, Other

MaterialCarbon Steel

StandardASME

Ss Intermediate Flange Application: Industrial

ApplicationIndustrial

MaterialStainless Steel

ColorMetallic

Socket Weld Y Type Strainer - Cast Steel Body with 40 Mesh SS Screen | Reliable Pressure Handling in Industrial Applications

Payment TermsCash on Delivery (COD), Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Delivery Point (DP), Cash in Advance (CID), Cheque

Delivery Time3-4 Week

Sample AvailableYes

Mahavas Precision Controls Private Limited

Pune

Trusted Seller

Trusted Seller7 Years

Gray Ss Valve Flanges

Price: 100 INR/Piece

MOQ20 Piece/Pieces

Product TypeOther

MaterialStanless Steel

StandardOther

ShapeRound

SurfaceGalvanized

ColorGray

Bhagyalaxmi Engineering Works

Ahmedabad

Aluminum Orifice Flanges - Round Design, Rust Resistant | Precision Flow Control & Corrosion Resistance

Price: 200 INR/Piece

MOQ1 Piece/Pieces

FeatureRust Resistant

Product TypeOther, Orifice Flanges

MaterialAluminium

ShapeRound

Renaissance Fittings & Piping Inc.

Mumbai

Super Seller

Super Seller8 Years

Latest From Flanges

Ready To Ship Flanges

Flanges - Introduction

Flanges are the second most used longer-able, after welding, because they provide a secure way to combine pipe systems with the numerous equipment, valves, and other elements of nearly any processing system.

Flanges increase system maintenance adaptability by permitting faster disassembly and better access to system components.

Pipes, valves, fittings, and specialized equipment like strainers and pressure vessels all make use of flanges to connect to one another and to other parts of the system. Blind flanges are made by joining a cover plate together. Bolting is used to connect flanges, and gaskets or other sealants are commonly used to ensure a watertight connection.

Common Types of Flange

1. Orifice Flanges

Pipeline pressure and flow may be accurately gauged and controlled with the help of orifice flanges and orifice plates. A complete set includes the plate and jack screws, which are also sold separately.

2. Socket Weld Flanges

Socket weld flanges are used to construct fittings for smaller, higher-pressure pipes, such as hydraulic pipelines.

3. Blind Flanges

Blind flanges are used to seal off segments of pipe because they lack a bore. They can withstand high pressure and can be used to verify the passage of a gas or liquid through a conduit.

4. Threaded Flanges

In contrast to slip-on flanges, threaded pipe flanges include a tapered thread that allows them to be mounted to pipes without welding. They are similar to slip-on flanges in that they perform best in low-pressure, low-temperature settings.

5. Slip-on Flanges

Flanges with slip-on connections are welded on both the inside and the outside of the pipe. They're great for low-pressure, low-temperature uses, and they're inexpensive and widely utilized.

6. Weld Neck Flanges

These hefty flanges, known as "necked" flanges due to their projecting necks, are designed to withstand the same high temperatures and pressures as the pipes they are attached to.

7. Long Weld neck Flanges

In contrast to standard weld neck flanges, the neck (tapered hub) of long weld neck flanges ("LWN") is lengthened to serve as a boring extension. Vessels, columns, and barrels often include long weld neck flanges. Both heavy barrel (HB) and equal barrel (E) versions of these flanges exist.

8. Lap Joint Flanges

Flanges used in a lap joint have a flat face and are always connected to a stub end. To accommodate the flanged portion of the stub end, lap joint flanges have a radius at the crossing of the flange face and the bore. A lap joint Flanges is made by sliding a flange over the pipe and seating it on the rear of the stub end, then tightening the bolts to hold the two pieces together.

9. NipoFlange

A Nipoflange is made by joining a welding neck flange and a forged Nipolet, and it is used for 90-degree branch pipelines. A Nipoflange, on the other hand, is not comprised of two separate goods but rather a single piece of forged steel.

10. Weldo Flanges

Both the Nipoflange and the Weldoflange are hybrids of the weld neck flange and the branch fitting connection (a Weldolet in this case). Weld Flanges are not assembled from smaller pieces of steel but rather are manufactured from a single piece of steel that has been forged into the desired shape.

11. Swivel Flange

Subsea and offshore pipelines, similar environments, Installation of large diameter pipelines, and pipe works in shallow waters benefit greatly from the alignment of the bolt holes between the two mating flanges made possible by swivel ring flanges.

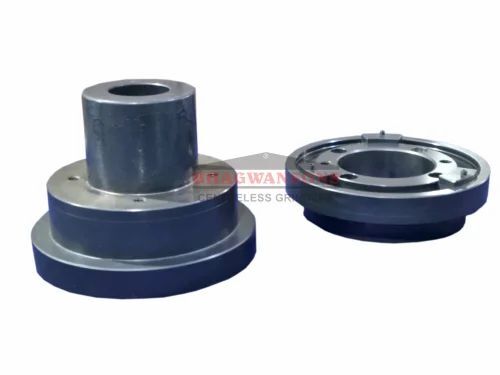

12. Expanding Flange

The image depicts an expanding flange, which is actually a welding neck flange with a bigger bore on the end that is not flanged. Run pipe bores can be enlarged with expanding flanges, but only by a single size (from 2 inches to 3 or 4 inches, for example).

13. Reducing Flange

In contrast to the expander flanges, which are used to increase the diameter of a pipeline, reducing flanges (also known as reducer flanges) are employed to lower the bore of the pipe. Only one or two sizes can be safely subtracted from the run pipe's bore before resorting to a hybrid solution using a butt weld reducer and a standard flange.

Characteristics of Flange

Common face characteristics of flange include:

Flat Face (FF): Flat face flanges, as the name implies, have a smooth, level face with a gasket that makes full contact with the flange's face.

Raised Face (RF): These flanges have an inner bore circle gasket and a tiny elevated portion around the bore.

Ring Joint Face (RTJ): This face style is ideal for high-pressure and high-temperature applications because of the groove it provides for a metal gasket.

Tongue and Groove (T&G): These flanges are designed with complementary grooves and protrusions. This facilitates assembly because the flanges may align themselves and a reservoir for gasket glue is provided in the design.

Male & Female (M&F): These flanges employ a gasket retention method analogous to that of tongue-and-groove flanges, with a corresponding set of grooves and elevated parts. These flanges are similar to tongue and groove flanges, except that the gasket is retained on the female face, which allows for more precise positioning and a wider variety of gasket materials.

Flanges Mechanical characteristics:

| Grade | Tensile Strength | Yield Strength 0.2% Offset | Elongation |

| F1 | 275 | 485 | 20% |

| F5 | 275 | 485 | 20% |

| F9 | 380 | 585 | 20% |

| F11 | 205 | 416 | 20% |

| F12 | 275 | 486 | 20% |

| F22 | 205 | 415 | 20% |

| F91 | 380 | 585 | 20% |

How Do Flanges Work?

1. Operation:

The outside of a pipe flange is flat and perpendicular to the pipe it is attached to. Bolts, collars, adhesives, or welds are some of the mechanical methods used to attach two of these surfaces together.

Welding, brazing, or threading are the most common methods used to secure flanges to pipes.

The welding process involves fusing two pieces of metal together with the help of a filler metal. Welding is typically the best method of flange connection for strong, high pressure connections of the same or similar materials. The vast majority of pipe flanges are made to be welded onto pipes.

During brazing, a filler metal is melted and then utilized to permanently connect two pieces of metal. Tighter tolerances and cleaner joins are possible since the workpieces are not melted and thermal distortion is avoided. As an added bonus, it can be used to join together materials with a wide range of chemical and physical properties, including metals and metal-coated ceramics.

Flanges and pipes are threaded so that they can be joined together with a nut-and-bolt style connection.

When choosing a pipe flange, the attachment technique is just one factor among many. The physical characteristics, type, material, and performance attributes of the flange are the most important to an industrial buyer.

2. Flange Materials

Pipe flanges can be made from a wide variety of materials, including stainless steel, cast iron, aluminum, brass, bronze, plastic, etc., although forged carbon steel with machined surfaces is by far the most common.

In addition, "lined flanges," which are used for specialized purposes, are inside furnished with layers of materials of an entirely different grade as the flanges directly, much like fittings and pipelines.

A flange's material is often determined when the pipe is selected. Flanges are typically made from the same metal as the pipe.

Unless otherwise specified, the ASME and ASTM standards apply to all flanges covered here. Dimensions, dimensional tolerances, etc. are described in ASME B16.5, while ASTM details the various material characteristics.

3. Dimensions of Flanges

Flanges can only be properly sized if the exact physical measurements are given.

a- The OD of a flange is the circumference measured outside its face from its two outermost edges.

b- The flange holding the pipe is not counted toward the thickness; rather, it relates to the thickness of the outside rim used for attachment.

c- In order to determine the diameter of a bolt circle, measure the distance between the centers of two bolt holes.

d- Pipe size is the standardized measurement of a pipe flange's internal diameter. Typically, nominal pipe size (NPS) and schedule are used as the dimensionally-independent identifiers (SCH).

e- The nominal bore size is the measurement of the flange's internal diameter. It is crucial to consider the bore size of the mating pipe when fabricating and placing an order for any kind of pipe connector.

Where are Flanges Used?

Flanges, which are forged rings of varying sizes and forms, are used in a broad variety of industries around the world to join valves, pipes, and other pieces of equipment. The most prominent and widespread applications of Flanges are outlined below.

1. Mechanics

Flanges and bolts are useful for joining two parts of a big, enclosed area together. This is how engineers safeguard the inner workings of the engine and transmission by joining their outside casings.

2. Electronic

In cameras and other electronic gadgets, flanges provide a specific function. Flanges in such products often don't need to withstand high pressures, but they do need to be secure to prevent dangerous particles from escaping. These flanges are used to join dissimilar materials, such as a camera lens and its metal mount.

3. Vessels

Flanges are typically utilised on ships where a longer neck is required. flanges (LWN) are used primarily on vessels when a longer neck is required. Due to its distinctive extended neck or hub that serves as a bored, this flange is classified as a peculiar type.

4. Piping

Flanges allow for the quick and easy assembly of piping parts using bolts. Flanges are used to join together two pipes, or to attach a pipe to a valve, a fitting, or a specialised device like a strainer or a pressure vessel.

In order to make a blind flange, a cover plate must be attached. Flanges are usually bolted together, and gaskets or other sealants are used for the joints.

5. Valves

A form of connection known as a flange valve connection is one in which a gasket is placed between the flanges of a pipe and a valve in order to seal the joint. Bolts are used to keep it in place, and a leakproof seal will be produced by the flange connections if they are placed properly.

Features of Flanges

1. Provide better flexibility

You probably have pipelines in some inaccessible places. More adapter-free adaptability is necessary in those regions. Flanges provide for more freedom of movement in pipes without the need for adapters.

2. They fit well in tight space

Frequently, pipes must work in confined areas. When a wrench won't fit, traditional flange fittings are simple to install. Easy assembly with low to moderate torque allows for more compact storage.

3. Provide easy maintenance

In terms of upkeep, a flanged connection couldn't be simpler. This is especially the case for straight lines inside of unbroken pipes or metal tubes.

With flanges, manifold, tube, and hose connections can be quickly disassembled, reassembled, and repositioned with no interference, facilitating routine maintenance.

4. Connections and fittings

Flange connections and fittings are more secure than regular hydraulic fittings. Furthermore, they lessen the possibility of other parts coming free during rigorous hydraulic use. In place of that, they essentially clamp around a flange head to distribute force more evenly.

5. They are more robust than traditional hydraulic fittings

Pipe connections are easily harmed by vibrations, high pressure, or shock pressures when utilising standard hydraulic fittings. However, flange connections work wonderfully for both straight and curved sections of pipe.

It is possible that the assembly of a pipeline bend that is subjected to significant lateral forces will become loose if flanges are not used.

Top Flanges Manufacturers and Suppliers in India

1. Manifold Pipe Solutions

In 2016, Manifold Pipe Solution Inc., opened doors. In the industry of carbon steel flanges, they are the go-to experts. Steel fasteners, steel flanges, and steel round bars with a wide range of materials, thread shapes, and surface treatments are produced by this expertly managed firm.

2. Western Steel Agency

Carbon steel flanges are a specialty of Western Steel Agency, which is a leading manufacturer, distributor, and exporter in India. Products are manufactured to exacting global quality standards. There is a high demand for carbon steel flanges in the metalworking sector.

3. Excel Metal & Engineering Industries

Excel Metal & Engineering Industries is a leading manufacturer and supplier of carbon steel flanges based in India. Among the many types of pipe fittings available are carbon steel flanges, pipe swivels, and tees. The engineering, petroleum, and automotive sectors all make use of these items regularly.

These vary in size and shape and are crafted from premium materials. When it comes to importing, stocking, supplying, and exporting, Excel Metal & Engineering Industries has been a frontrunner since 1990.

4. SkyLand Metal & Alloys Incorporation:

Skyland Metal Metal & Alloys, has been an ISO 9001:2000 certified supplier of metals and alloys to customers around the world since 1991. Skyland Metal & Alloys is a leading producer, stockist, and supplier of both ferrous and non-ferrous metals.

5. Metline Industries

The Indian market for pipe fitting accessories is a growing and dynamic area of business for Metline Industries. India and China are home to the manufacturing plants. The ASME, EN, ISO, and other international standards are all met by their goods.

Flanges are used for joining together various pipeline components like pumps and valves. Usually, flanges are joined together using welding or thread screws. Flanges make it simple to do routine inspections and repairs on a pipe network.

FAQs: Flanges

Q. How to Select Flanges?

Ans: Here are the top 3 important considerations to select the right flanges:

- Check the size

- The type of flange

- And the materials

Q. Why is flange used?

Ans: Flanges are used to connect pipes to each other, to valves, fittings, and to special items like strainers and pressure vessels.

Q. What is the difference between ASME and DIN flanges?

Ans: DIN Flanges have a tolerance of 0.11, while ASTM Flanges have a tolerance of 0.218. This is a difference of 0.108mm.

Q. What is a flange pipe?

Ans: A Flange pipe connects pipes and components in a piping system with bolted connections and gaskets. Weld neck flange, slide on flange, threaded flange, socket weld flange, blind flange, and lap joint flange are the most typical types of flanges (RTJ Flange).

Q. How are flanges connected to pipes?

Ans: Threading, brazing, or Welding are the most common methods used to secure flanges to pipes. The welding process involves fusing two pieces of metal together with the help of a filler metal.

Q. What are the main types of flanges?

Ans: Here are the types:

a- Threaded flange

b- Blind Flange

c- Slip-on Flange

d- Socket Weld Flange

e- Welding Neck Flange

Q. What is the size of the flange mostly used?

Ans. The standard sizes are:

a- 150

b- 300

c- 400

d- 600

e- 900

f- -1500

g- 2500

Q. What is the price of flanges in India?

Ans: The price of flanges varies depending on the size of the pipes. The indicative price of a flange for a 3” inch pipe would be around Rs.350 whereas for a 4” pipe would be around Rs.480.

Q. How do flanges prevent leakage?

Ans: Flanges by themselves are not capable of preventing leakage. For preventing leakage, a wide rubber gasket is sandwiched between the flanges that create a vacuum sealing at the joint.

Q. What is meant by threaded flanges?

Ans: Threaded flanges contain thread for screwing with the pipes and then bolted and sealed with a gasket.

Q. What are the advantages of flanges?

Ans: A flange joins two pipes very strongly. It distributes the load at the joint. Flanges also make repairing works easy as they create a break in the pipeline.

Related Topic:

Flanges Manufacturers, Suppliers & Exporters In India [Top 10]

Manufacturers & Suppliers of Flanges

Company Name | Member Since |

|---|---|

Niko Steel And Engineering Llp Mumbai, India | 23 Years |

Aim Tech Jalandhar, India | 17 Years |

Indian Iron & Steel Suppliers Kolkata, India | 17 Years |

Fidicon Devices India Private Limited Ankleshwar, India | 16 Years |

Procon Technologies Pvt. Ltd. Ahmedabad, India | 15 Years |

Tube Fit Industries Mumbai, India | 14 Years |

Inder Industries Jalandhar, India | 11 Years |

Nascent Pipes & Tubes Mumbai, India | 11 Years |

H C & Company Pune, India | 11 Years |

Unique Industrials Secunderabad, India | 10 Years |

Popular Products