Forged Pipe Fittings

(695 products)Round Stainless And Duplex Steel Forged Fitting

MOQ10 Piece/Pieces

MaterialStainless Steel

TypeWelded

ShapeRound

ConnectionSocket joint

FinishingOther, Polished

SizeCustomized

Renaissance Fittings & Piping Inc.

Mumbai

Super Seller

Super Seller8 Years

Stainless Steel Railing Pipes - Shape: Round

Price: 138 INR/Kilograms

MOQ1000 Kilograms/Kilograms

MaterialStainless Steel

TypeOther, Railing Pipes

ShapeRound

FinishingFinished Polished, Other

Size3,1,3/4,2,1/2

Thickness0.5 to 3.25 Millimeter (mm)

Hastelloy C276 Forged Pipe Fittings - ASTM B564 & ASME SB564 | Size 1/8 NB to 4 NB, Socketweld & Screwed-Threaded, Class 2000 to 9000 LBS

Price: 1000.0 INR/Piece

MOQ150 Piece/Pieces

Material', ], ', O, t, h, e, r, , [

StandardO, t, h, ], ', e, r, ', [

Finishingv, a, n, i, ', ], G, z, e, d, [, ', a, l

Size1/8 NB to 4 NB (Socketweld & Screwed-Threaded)

GradeHastelloy C276

Ms Forged Plug Threaded - Material: Iron

Price: 25 INR/Piece

MOQ10 Piece/Pieces

MaterialIron

TypeOther, MS FORGED PLUG THREADED

ShapeRound

Size1/8" aEUR" 3"

Nickel Alloy Forged Fittings - Nickel Material, High Durability | Heavy-Duty Performance, Corrosion Resistance

Price Trend: 250.00 - 350.00 INR/Piece

MOQ25 Piece/Pieces

MaterialNickel

TypeOther

1 Inch Size Forged Technics Made Plumbing Use Female Connection Galvanized Iron Tee Grade: Industrial

MOQ100 Kilograms/Kilograms

Product TypeTee

TypeGalvanized

GradeIndustrial, Domestic

Socket Weld Elbow - Carbon Steel, 2-100 mm Thickness | Galvanized Finish, AISI Standard, High-Pressure Compatibility

Price: 100 INR/Unit

MOQ500 Kilograms/Kilograms

MaterialCarbon Steel

StandardAISI

Surface TreatmentGalvanized

Thickness2-100 Millimeter (mm)

F 61 - Stainless Steel Forged Fittings - Size: 1/8" To 4"

MOQ100 Piece/Pieces

MaterialStainless Steel

UsageIndustrial

TypeSeamless

TechnicsHot Rolled

StandardASME

Size1/8" to 4"

Stainless Steel Forged Reducing Coupling

Price: 100 INR/Piece

MOQ100 Piece/Pieces

UsageIndustrial

Material GradeA

MaterialStainless Steel

ShapeRound

ApplicationIndustrial

TypeOther, Stainless Steel Forged Reducing Coupling

Shakti Forge Industries Pvt. Ltd.

Rajkot

Trusted Seller

Trusted Seller2 Years

Manual Polish Forged Pipe Fittings

Price: 40 INR/Piece

MOQ200 Piece/Pieces

Product TypeElbow

MaterialStainless Steel

ShapeRound

FinishingManual Polish

GradeIndustrial Grade

Mubarak Forging Works

Mumbai

Trusted Seller

Trusted Seller7 Years

Forged Pipe Fittings By Excel Metal & Engg Industries

Price: 99 INR/Number

MOQ10 Number

Product DescriptionForged Pipe Fittings

Excel Metal & Engg Industries

Mumbai

Threaded Half Coupling Grade: Industrial

MOQ10 Piece/Pieces

MaterialOther , Metal

TypeGalvanized

ShapeRound

FinishingOther, Polished

Surface TreatmentGalvanized

SizeDifferent available

Supreme Steel & Engineering Co.

Mumbai

Galvanized Forged Plumbing Pipe Tee

MOQ5000 Piece/Pieces

Product TypeTee

MaterialBrass

TypeSeamless

FinishingGalvanized

SizeStandard

WarrantyYes

Forged Fittings Welded Elbow - Stainless Steel Multigrade, Galvanized Finish with Warranty

MOQ100 Piece/Pieces

Product TypeTee

MaterialStainless Steel

TypeGalvanized

GradeMultigrade

WarrantyYes

Forged Stainless Steel Pipe Fittings

Product DescriptionForged Stainless Steel Pipe Fittings We are the prominent manuf

Galvanized 90 Degree Forged Pipe Elbow

MOQ50 Piece/Pieces

Product TypeElbow

MaterialCarbon Steel

TypeGalvanized

FinishingGalvanized

Surface TreatmentGalvanized

SizeDifferent Available

Carbon Steel Forged Hex Nipples - Shape: Round

Price: 250 INR/Piece

MOQ10 Piece/Pieces

MaterialCarbon Steel

TypeCarbon Steel Forged Hex Nipples

TechnicsHot Rolled

ShapeRound

Surface TreatmentGalvanized

Mild Steel Coupling Hardness: Hard

Price: 50 INR/Piece

MOQ100 Piece/Pieces

ProcessNormal

HardnessHard

Product TypeCoupling

MaterialMild Steel

TechnologyForging

TypeSeamless

Bhavani Steel Forging Industries

Rajkot

Trusted Seller

Trusted Seller2 Years

Tee Forged Pipe Fittings

Product DescriptionOur customers can avail from us superior quality Tee Forged Pipe Fittings. These Tee Forged Pipe Fittings are procured from most trusted and reputed companies that are always preferred to supply flawless and standard products. These products are available in market at most economical rates

Ramdevra Forged Pipe Fittings

Product DescriptionWith the help of our skilled and experienced personnel, we are able to offer a superior quality range of Forged Pipe Fittings. These products are developed from finest quality raw material and advanced technology in compliance with the set industry standards and norms. These products are well known

Socket Weld Elbow

Price: 1500 INR/Piece

MOQ10 Piece/Pieces

Supply Ability1 Per Day

Delivery Time1 Days

Forged Pipe Elbow - Finishing: Galvanized

MOQ100 Piece/Pieces

MaterialOther , MS

TypeSeamless

StandardAISI

FinishingGalvanized

GradeMultiple Available

Warranty1 Year

R K Forged Pipe Fittings

Product DescriptionForged Pipe Fittings that we provide to our customers are precision manufactured carbon and mild steel forged pipe fittings. Our products in this collection are in compliance with ANSI b 16. 11 specifications. We offer these items in various dimensions and numerous grades. In addition, these have sp

Forged Pipe Reducer - Finishing: Mirror Polish

MOQ100 Piece/Pieces

MaterialMild Steel

TypeSeamless

ShapeRound

FinishingMirror Polish

Surface TreatmentOther, Polished

M/s Rakesh Chandra Vishal Chandra

Lucknow

Galvanized Pipe Fittings - Carbon Steel 90 Deg Threaded Elbow, Customized Diameter, Thickness, and Finishing

Price Trend: 80 - 5000 INR/Piece

MOQ50000 Piece/Pieces

Product TypeElbow

FinishingPolished, Other

SizeCustomize

GradeCustomize

DiameterCustomize Millimeter (mm)

ThicknessCustomize Millimeter (mm)

Forged Tee - High-Strength Alloy Steel, Various Sizes and Finishes | Precision Engineered to International Quality Standards

Product DescriptionWe are amongst one of the foremost organization engaged in distributing, trading and supplying an enormous range of Forged Tee in Vadodara, Gujarat, India. Our offered range of forged tee is precisely designed and developed by our vendors' experts in complete compliance with the international qualit

Galvanized Socket Weld 90 Degree Elbow

Price Trend: 200-20000 INR/Piece

MOQAs per order Piece/Pieces

Product TypeElbow

MaterialStainless Steel

TechnicsHot Rolled

ConnectionWelding

StandardASTM

FinishingGalvanized

Latest From Forged Pipe Fittings

Forged Pipe Fittings

By:

Shakti Industries

Stainless Steel Forged Pipe Fittings

By:

Neptune Metal Industries

SHUBHAM Forged Pipe Fittings

By:

Shubham Tubes & Engineers

SHIKHAR Forged Pipe Fittings

By:

Shikhar Steel Corporation

Alloy Steel Forged Fittings

By:

National Enterprises

SEA Forged Pipe Fittings

By:

Sea Rock Steels

Stainless Forged Fittings

By:

A Metalex Industrial Corporation

SS Forged Fittings

By:

R. B. Metal & Tubes

SRI JAGANNATH Forged Pipe Fittings

By:

Sri Jagannath Enterprise

Explore More Cities

Ready To Ship Forged Pipe Fittings

All About Forged Pipe Fittings

Introduction

There are forged pipe fittings that conform to MSS-SP-79, BS3799, -83, -95, and -97, and the American Society of Mechanical Engineers' standard, B16.11. Nominal bore pipes can be joined with ease using these fittings. A105 carbon steel and SS316 stainless steel are used in their construction. These connections can range in size from 1/8 inch to 4 inches.

The term "forged fitting" refers to the method by which these components are produced. These fittings are made by heating the raw material, typically a steel alloy or carbon alloy, and shaping it to the manufacturer's specifications.

Weld socket pipe fittings and threaded pipe fittings are the two common types of forged pipe fittings. A105 carbon steel, stainless steel, and nickel alloy are all used in the production of these pipe fittings. Pipe fittings can be easily fabricated from any of these materials. Pipe fittings that have been forged are thicker, heavier, and designed for more substantial use.

Manufacturing of Forged Pipe Fittings

Manufacturers must adhere to a strict set of guidelines when creating pipe fittings with a particular brand name. Every forged fixture has a stamp on the collar that verifies its authenticity. This labeling is for the express purpose of identifying the specification of pipe fittings and informing the user.

It also facilitates the orderly execution of buying and choosing procedures. Marks on forged pipe fittings often include the manufacturer's name and logo, along with details on the product's place of origin, standards, size, work pressure capacity, material, and pressure.

Forged pipe fittings typically have a maximum allowable pressure of between 3000 and 6000 lbs. As a general rule, carbon steel is a reliable standard material. A different substance, like SS 316, leaves a mark on the body of the fitting.

Types of Forged Pipe Fittings

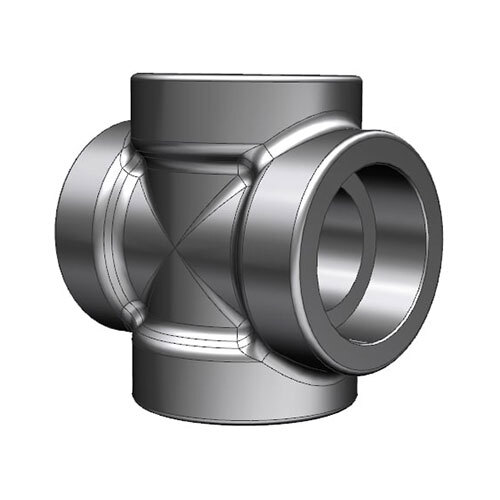

1. Cross

A cross is a 4-way forged steel fitting with either one inlet and three outlets or three outlets and one inlet. These connectors are also known as 4-way tees.

2. Plug

Plugs, which are forged steel fittings fitted into the pipe's end like caps, come with a variety of head shapes like hex, square, and round.

3. Caps

Caps are forged steel fittings that are inserted over the end of the pipe to stop the passage of fluids.

4. Bushings

In order to change the diameter of a pipe, forged steel fittings called reducing inserts and bushings are used. Hex head bushings, like the one seen above, are extremely popular.

5. Unions

Unions are a type of forged steel fitting that can be disassembled and reassembled easily; they have a nut, a female end, and a male end. They make it possible to connect and disconnect two pipe sections without inflicting any damage on the pipes themselves.

6. Couplings

One end of a half-coupling is designed to be snugly inserted into, or welded onto, the opposite end of a pipe or vessel, and it is screwed into the pipe to complete the connection. Reducing couplings allow smaller pipes to be connected to bigger ones, while standard couplings feature female threads or open sockets at both ends.

7. Elbows

Pipe elbows are steel fittings used to reverse the direction of two lengths of pipe or tube, typically by 90 degrees or 45 degrees. Reducing elbows, like reducing tees, are used to do the same thing, but they do so by reducing the width of the pipe at the same time as redirecting the flow. To facilitate installation without a pipe nipple, Street Elbows feature a male end threaded to the same size as the pipe at the female end.

8. Tee

Forged steel tees and reducing tees are used to join or separate fluid streams in industrial applications. In addition, Forged Pipe Fittings tees provide a modification in the diameter of the pipe. Two of the tee's exits are inline and one is a branch. In a reducing tee, the outlet at the branch is the one that is reduced.

Features & Specifications of Forged Pipe Fittings

Specifications:

1. Standard

Fittings for pipes that are forged in accordance with SH3410, BS3799, ASME B16.11, GB/T14383,and other specifications. Forged pipe fittings are available from a number of manufacturers to meet the needs of the diverse clientele. Every one of their goods is manufactured to the highest possible specifications.

2. Size

Forged pipe fittings from DN6 to DN100 are available from the supplier.

It comes in a wide range of sizes. As a rule, they are diminutive in stature. That depends on the volume of output. Each size has a unique function in the process of forging. Customer requests for a certain keyboard layout are taken into consideration.

3. Pressure

The manufacturers are pressed to produce at 3000, 6000, 9000, and 10000 PSI. The PSI pressure rating for the forged pipe fittings is expressed in English as pounds per square inch.

4. Materials

Alloy Steel, Stainless Steel, Carbon Steel, A105, 20#, A350LF2, F347, F9, F22, F91, F304L, F11, F316L, 20Mn, ASTM A182 F5, F51, and so on may be used to make the forged pipe fittings.

5. Thickness

5-10mm, 10-15mm, 15-20mm

Features:

While titanium fittings are an excellent alternative to more traditional forged steel fittings, their higher price tag can quickly increase overall project expenses. What you get from forged steel:

- Superior strength and resilience

- Connections with no leaks

- Efficiency in spending

Get the long life expectancy of your pipes that you require without breaking the bank. You already know how crucial it is to save costs wherever possible when working with materials. Titanium pipe fittings are quite inexpensive individually, but the cost quickly adds up when you need many of them for a single job.

Applications of Forged Pipe Fittings

Forged fittings made from premium materials can be put to many different uses. Longevity, pressure, and flawlessness are all guaranteed by the forged fittings' one-of-a-kind reliability and uniformity in finish.

Such fittings find additional use in the pharmaceutical, chemical, oil refining, and other related sectors.

Chemical fertilizer, instrumentation, nuclear thermal, heat exchanger, oil gas, pharmacy & surgery, water gas pipe, and petrochemical refineries are just some of the many fields that benefit from these fittings.

A wide variety of uses call for High Pressure Forged Fittings to withstand extreme heat. It is put to use in the distribution of pressurized liquids and gases.

This quality accounts for its widespread application in the petrochemical and gas manufacturing industries. It's perfect for numerous operations that need to be done at temperatures above 500 degrees Celsius due to its exceptional welding and forming capabilities at those temperatures. As with the construction of vessels and oil refining machinery, pharmaceutical equipment manufacturing is just one possible use.

Best Quality Forged Pipe Fittings with Price

Buyers can check the range of forged pipe fittings online. There are various forged pipe fittings manufacturers available online dealing in a vast range of forged metal fittings. The fittings are made for application in pipeline system. Buyers can also have the option of forged steel pipe fittings for buying as per their needs. Check all details, such as dimensions, sizes, technical specifications and other needed information available online.

Buyers are also advised to check the features and other details, such as:

A. Quality standards

B. Raw material quality

C. Quality certifications

D. Tensile strength

E. Durability

F. Price

G. Delivery time

H. Minimum order quantity

Buy Forged Metal Fittings Online

Customers looking forward to buy Forged Metal Fittings online can get in touch with various manufacturers and suppliers dealing in high quality products. Online buying has become very convenient since the buyers can all specific and sundry details available.

When buying the buyers can also check other related sub-categories, such as:

- Mild steel forging tee

- Ms forged pipe fittings

- SS butt welded pipe fitting

- MS forged pipe fittings

- Aluminium forged pipe fittings

- Mild steel forged threaded pipe fittings

- Forged steel pipe fitting

- Nickel alloy forged pipe fittings

Interested buyers may check the contact details of forged metal manufacturers and suppliers, and share their order details with them.

FAQs: Forged Pipe Fittings

Q. What is metal forging?

Ans. Metal forging is a technique by which metals, generally iron and different grades of steel, are heated till it becomes softer to be hammered or casted into different types of pipe fittings.

Q. What is a 90o elbow?

Ans. A 90o elbow is used to turn the pipe direction at the right angle. The arc of the elbow forms one quarter of a circle and change the flow of direction there.

Q. In what types of joining mechanism are forged metal fittings made?

Ans. Forged metal fittings are made in threaded fittings and socket weld fittings.

Q. What is the difference between socket weld and threaded forged metal fittings?

Ans. Threaded forged metal fittings are fittings that are threaded (male and female or both) at the ends for connecting pipes, valves, pumps and others. Socket weld fittings are those fittings which have sockets for welding together two pipes or a pipe with other pipe fittings.

Q. . What are the advantages of forged metal fittings?

Ans. Forged metal fittings are strong, ensure uniformity of structure and composition in the finished components.

Related Blog Topic:

Best 10 Forged Pipe Fittings Manufacturers, Suppliers & Exporters in India

Manufacturers & Suppliers of Forged Pipe Fittings

Company Name | Member Since |

|---|---|

Mahavir Forge & Fittings Mumbai, India | 12 Years |

Jai Jirawal Metal & Alloys Mumbai, India | 10 Years |

Renaissance Fittings & Piping Inc. Mumbai, India | 8 Years |

Excel Pipe Fitting Co. Mumbai, India | 8 Years |

Shree Rajlaxmi Forge Mumbai, India | 7 Years |

Mubarak Forging Works Mumbai, India | 7 Years |

R K Trading Co Mumbai, India | 7 Years |

Rajdhan Metal Mumbai, India | 7 Years |

Triton Alloys Inc Mumbai, India | 6 Years |

Sagar Steel Corporation Mumbai, India | 6 Years |

Popular Products