Autoclaves & Sterilizers

(2639 products)Rectangular Horizontal Autoclave - Capacity: 35-213 Ltr

Price: 685000 INR/Unit

MOQ1 , Unit/Units

Operate MethodManual, Fully Automatic, Semi Automatic

MaterialStainless Steel

Voltage230 Volt (v)

Capacity35-213 Ltr

ColorSliver

UsageIndustrial

Patel Scientific Instruments Pvt. Ltd.

Ahmedabad

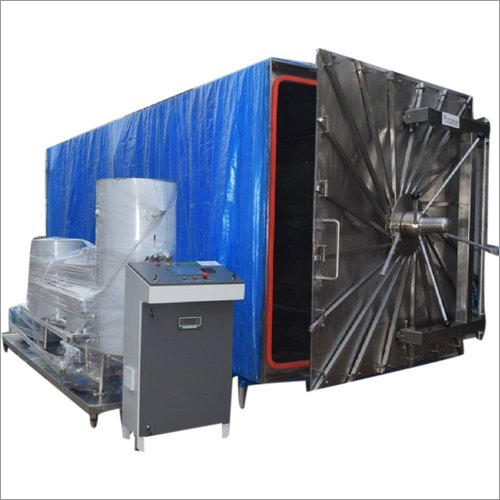

Industrial Autoclave With Quick Opening Doors

MOQ1 Set/Sets

Payment TermsTelegraphic Transfer (T/T), Western Union, Paypal, Others

Delivery Time1 Week

Sample PolicyContact us for information regarding our sample policy

Air Sterilizer - Compact ABS Plastic Design | Noise-Free Operation, Self-Cleaning Filter, High Power Air Ionizer, Easy Mobility

Payment TermsCash on Delivery (COD), Cheque

Sample AvailableYes

Main Export Market(s)Eastern Europe, Asia

Hospital Eto Sterilizer - Chamber Size: 50 To 220 Liter

Price: 350000.00 INR/Set

MOQ1 Set/Sets

UsageHospital, Healthcare & Pharma

MaterialStainless Steel

TypeGas Sterilization Equipments

Chamber Size50 to 220 Liter

Compressed Air6 CFM

Door TypeHinged Type

Industrial Eto Sterilizer Chamber Size: 2-720 Qubic Feet

Price Trend: 305000.00 - 800000.00 INR/Piece

MOQ1 Unit/Units, Unit/Units, Unit/Units

Capacity55 liter, 85 liters, 110 liters

MaterialStainless steel

Dimension (L*W*H)As per customer requirement

Operate MethodFully Automatic

ClassificationETO STERILIZER

ApplicationHospitals

Industrial Eto Sterilizer Chamber Size: 450L

Price: 1800000 INR/Unit

MOQ1 Unit/Units

Product TypeETO Sterilizer

Voltage220 Volt (v)

MaterialSS

ApplicationHospital

TypeOther, Single Phase

Chamber Size450L

Vertical Autoclave Standard - Capacity: 35 Ltr

Price: 165082 INR/Unit

MOQ1 Unit/Units

Capacity35 Ltr

ColorSilver

UsageIndustrial

Operate MethodSemi-Automatic

Dimension (L*W*H)A~12aEUR x 20aEUR Inch (in)

Power220 Volt (v)

High Pressure Autoclave - SS 316 & Hastelloy C | 100 ml to 100 Litre Capacity, Up To 100 Bar Pressure, Advanced Safety Features, Efficient Reaction for R&D Applications

Product DescriptionBanking on the individual requirements of the clients, we are the popular manufacturer and supplier a wide range of High Pressure Autoclaves in Mumbai, Maharashtra, India. These are performance based and are durable in nature. Our entire product range is functionally advanced and is configured with

Hra-Plus Rectangular Autoclave - Color: Silver

Price: 1500000 INR/Unit

MOQ1 Unit/Units

ColorSilver

UsageIndustrial

MaterialMild Steel

Operate MethodAutomatic

Voltage220-440 Volt (v)

World Invent Scientific Technology Private Limited

Vasai

Sterilizers - Superior-Grade Raw Material, Advanced Technology Design | Reliable Performance, Diverse Applications

Product DescriptionOwing to our proficiency in this domain, we have been able to satisfy the variegated requirements of the clients by manufacturing, exporting and supplying a wide array of Sterilizers from Surat, Gujarat, India. Our offered Sterilizers are designed and manufactured using superior-grade raw material

Silver Hmg Ce Slfa Series Single Lever Autoclave

Price Trend: 100000.00 - 700000.00 INR/Unit

MOQ1 Unit/Units

Product TypeSingle Lever Autoclave

ColorSilver

UsageIndustrial

MaterialStainless Steel

Humidity Chamber - High-Performance Stainless Steel, Adjustable Temperature Control, Precision Humidity Regulation

Price: 250000 INR/Number

MOQ1 Number

Product DescriptionHUMIDITY CHAMBER

Meta-lab Scientific Industries

Mumbai

White Eto Sterilizer Machine

Price: 3000000 INR/Unit

MOQ1 Unit/Units

MaterialSS

ColorWhite

Product TypeETO Sterilizer Machine

Storage InstructionsDry Place

SS Vertical Autoclave - 220-440V Silver | Industrial Usage, Durable Design

Price: 60000 INR/Unit

MOQ1 Unit/Units

Voltage220-440 Volt (v)

Product TypeSS Vertical Autoclave

UsageIndustrial

ColorSilver

Adrija Scientific Instrument Company

Kolkata

Medium Deep Tray

Product DescriptionWith immense experience of this domain, we are instrumental in Manufacturer & Supplier, a wide range of Medium Deep Tray in Ahmedabad, Gujarat, India. Our offered products are in high demand in the market. We are cent percent ensure about the product quality, at very affordable price range.\015\012

Vertical Steam Sterilizer, Frequency: 50 Hz

Product DescriptionVertical Steam Sterilizer

White Transformer Drying Autoclave

MOQ10 , Piece/Pieces

Product TypeTransformer Drying Autoclave

UsageIndustrial

Colorwhite

TypePressure Steam Sterilization Equipments

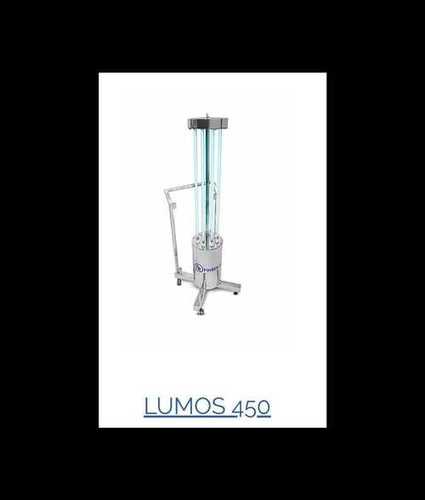

Laboratory Use Ultraviolet Sterilizers - Metal, 1342x453x550 cm | Easy to Operate, Best Quality, Long Life, Superior High Corrosion Resistance

Price: 90600 INR/Unit

MOQ1 Unit/Units

Power450 Watt (w)

Voltage220 Volt (v)

Dimension (L*W*H)1342*453*550 Centimeter (cm)

MaterialMetal

Product TypeLaboratory Use Ultraviolet Sterilizers

ApplicationFor Medical Use

Finsen Ritter Technologies Private Limited

Indore

Eto Sterilizer - Stainless Steel, Compact Design for Efficient Sterilization, User-Friendly Controls

Price Trend: 0.10 - 0.30 USD ($)/Piece

MOQ500000 Piece/Pieces

Supply Ability500000 Per Month

Delivery Time24-40 Days

Hangzhou Riches Import And Export Co. Ltd.

Hangzhou

Trusted Seller

Trusted Seller9 Years

Electric Laboratory Hot Air Oven 220 V 50 Hz, Single Phase, Weight 38 Kg

Price: 40000.00 INR/Unit

MOQ1 Unit/Units

Weight38 Kilograms (kg)

Voltage220 Volt (v)

MaterialMetal

ColorBlue,Grey

UsageLaboratory

Product TypeHot Air Oven

Vertical Autoclave - Stainless Steel, 230 Volts 50 Hz, 15-20 PSI Pressure | Industrial Sterilization with Jointless Silicon Rubber Gasket, 121°C Operating Temperature

Price: 1 INR/Piece

MOQ1 Unit/Units

Voltage220-240 Volt (v)

ApplicationIndustrial

MaterialSS

Yesha Lab Equipments

Ahmedabad

Trusted Seller

Trusted Seller7 Years

Dewaxing Autoclave - Durable Stainless Steel Construction | Efficient Wax Elimination, High-Pressure Capabilities, Optimal Temperature Control

Price: 3000000 INR/Piece

MOQ1 Piece/Pieces

Product DescriptionDewaxing Autoclave

Utech Projects Pvt. Ltd.

Mumbai

Super Seller

Super Seller14 Years

SS Autoclave - Stainless Steel, 220-440 Volt Automatic Operation | Industrial Application, High Efficiency

MOQ1 Unit/Units

MaterialSS

Operate MethodAutomatic

ApplicationIndustrial

Product TypeAutoclave

Power220-440 Volt (v)

Cee Dee Vacuum Equipment Pvt. Ltd.

Pune

Manual Bottle Sterilizer

Price Trend: 500000.00 - 200000.00 INR/Unit

MOQ1 Unit/Units

TypeSteriliser

MaterialStainless Steel

ComputerizedNo

Automatic GradeManual

Voltage220 - 240 Volt (v)

Warranty6 Months

Ss Engineers And Consultants Private Limited

Rajahmundry

ETO Sterilize

Price: 200000.00 INR/Piece

MOQ1 Piece/Pieces

Supply Ability3 Per Week

Delivery Time4 Months

High Grade Bacteriological Incubators

MOQ2 Number

Payment TermsTelegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

Supply Ability50 Per Week

Delivery Time2-3 Days

Krishna Meditech

Ambala Cantt

Trusted Seller

Trusted Seller7 Years

Fully Automatic Vertical Autoclave - Metal Composition, Silver Finish | Ideal for Industrial Applications, Fully Automatic Functionality

Price: 65000 INR/Unit

MOQ1 Unit/Units

UsageIndustrial

ColorSilver

Product TypeFully Automatic Vertical Autoclave

MaterialMetal

Sterilizer

Product DescriptionWe are instrumental in manufacturing, exporting and supplying a broad variety of Sterilizer in Chennai, Tamil Nadu, India. Offered Sterilizer is designed and manufactured according to set industry standards. The offered Sterilizer is manufactured from superior quality raw material with the aid of st

Tavron Engineers

Chennai

Trusted Seller

Trusted Seller12 Years

Explore More Cities

Ready To Ship Autoclaves & Sterilizers

What Are Autoclaves & Sterilizers

Introduction

The words steam sterilizer and autoclave are equivalent and can be used indiscriminately. That stated, an autoclave is generally employed in lab conditions, while a sterilizer is more typically used in hospital or pharmaceutical environments.

Autoclaves are also referred to as steam sterilizers and thus are primarily utilized for healthcare or commercial processes. An autoclave is a device that employs steam under pressure to destroy spores, viruses, fungus, and hazardous bacteria on goods that are deposited from the inside of a pressure vessel. The goods are heated to an appropriate sterilizing temperature for a specific amount of time. The moisture in the steam efficiently heat moves to the goods to destroy the structure of a protein of the bacteria and spores.

Different Types of Autoclaves & Sterilizers

1. Vertical Autoclaves

These autoclaves have a top lid that opens for loading. Particularly well suited for use in confined locations such as laboratories or minor clinics. This means their chamber is smaller as well. Some may have two chambers, each holding anywhere from 500 to 1500 liters.

Manufacturers set the autoclave's capacity. Manufacturers provide large autoclaves with capacities ranging from 510 to 1580 liters. It can be utilized in clinical and research settings as well as healthcare facilities.

2. Horizontal Autoclaves

Larger capacity front-loading steam sterilizers. This one is great for relieving stress on medical professionals when space is not a concern and a high volume of loads needs to be treated each day.

3. Gravity Displacement Autoclaves

Autoclaves that use high-pressure steam to push the air out of the chamber are very frequent. While they can't handle as much as pre vacuum autoclaves can, they're still sufficient for handling simple loads like flat medical instruments and certain biohazard waste.

The autoclave's steam displacement function is sufficient for sterilization because most media or items to be sterilized have a straightforward design that doesn't include spaces or impediments for steam to enter.

Given these considerations, gravity autoclaves have established themselves as the market standard and are the autoclave of choice for the vast majority of applications.

4. Pre-Vacuum Autoclaves (PREVAC)

Gravity autoclaving sometimes called gravity displacement autoclaving, is the simplest form of autoclaving and is sufficient for sterilizing the media most commonly used in labs. Steel cutlery, glassware, and potentially infectious garbage fall under this category.

During a gravity-induced autoclaving process, steam is pumped into the autoclave chamber. This causes the surrounding air to be pushed out through the exhaust valves, leaving just the sterilizing steam within to do its job.

This method helps displace ambient air with steam, and it does so in a straightforward fashion that doesn't rely on any ancillary mechanisms. Increasing the availability and affordability of autoclaves of this type.

5. Vacuum Autoclaves

Where air cannot be readily removed from sterilization media, vacuum autoclaving—also referred to as pre-vacuum autoclaving or sterilizing—is the preferred method of sterilization.

Sterilization of large or porous materials like animal cages and bedding, as well as packaged medical supplies, may fall into this category. When the surrounding air is removed from the autoclave, the high-temperature steam can reach and disinfect places that would typically be filled by ambient air, resulting in a more thorough treatment of the contents.

This is especially useful for sterilizing items with difficult-to-reach interior spaces.

6. S Class Autoclaves

Another form of gravity displacement Autoclaves & Sterilizers, this one employs a wall of thick steam; however, by repeating this procedure three times, all of the air is extracted from the chamber, allowing it to treat bagged instruments and porous loads. Class B autoclaves are still faster and more flexible.

7. Class N Autoclaves

It's best to think of these as basic autoclaves, in which only a fraction of the air in the chamber is evacuated via gravity. It is created to handle lighter loads such as flat medical instruments.

8. Large Steam Sterilizers

Typically, the volume of these autoclaves is between 110 and 880 liters. If I am perfect for major medical facilities such as hospitals that use a lot of medical equipment and generate a lot of waste every day.

9. Medium –Sized Steam Sterilizers

These autoclaves typically have a volume capacity between 75 and 200 liters. Perfect for use in dental offices, other medical clinics, biotech labs, and hospital operating rooms.

10. Benchtop Steam Sterilizers

The average size for an autoclave of this sort is 25 liters. These small steam sterilizers are ideal for clinics and hospitals that don't have a lot of room and don't need to disinfect as many instruments daily.

Applications of Autoclaves & Sterilizers

a. Many fields, including microbiology, veterinary science, mycology, etc., make extensive use of autoclaves.

b. Glassware, equipment, tools, surgical implements, needles, seizures, heat-resistant gloves, containers, and closures are just some of the things that can be sterilized with this method.

c. When it comes to sterilizing biological media, the autoclave is the gold standard.

d. Several pharmacopeial sources advise using autoclaves to sanitize injectable drugs.

e. Pre-disposal treatment and sterilization of waste materials emitted from pathogenic areas, such as hospital waste, is a rising use for autoclaves.

The autoclave chamber can be used to sanitize instruments in medical or laboratory fields by heating them to temperatures over the boiling point. Tabletop autoclaves, about the size of a microwave oven, are standard in most medical facilities. Large horizontal autoclaves are commonly used in hospitals.

Sterilization machines can process a large number of surgical instruments in a single sterilization cycle, allowing them to keep up with the constant need for clean equipment in operating rooms and emergency wards, where they are typically housed.

Components of Autoclaves & Sterilizers

1. Vessel

The autoclave's interior chamber and protective outer jacket make up the vessel. The "jacketed" chamber design used in the laboratory and hospital autoclaves allows for faster sterilization cycles and less condensation buildup inside the chamber.

2. Control System

Like the interfaces on a microwave or oven, modern autoclaves feature a controller. However, autoclaves typically have control systems that are more complex than those of typical home appliances.

The software formula for a sterilization cycle determines the order in which valves and other components are opened and closed.

3. Thermostatic Trap

An autoclave's thermostatic trap or steam trap is a device that lets air and water (condensate) escape from the chamber. Many different kinds of traps may be used in a steam delivery system or steam autoclave, but they all serve the same general purpose of keeping dry steam from escaping.

4. Safety Valve

Since autoclaves run at high pressures (14-45 psi gauge), they must be built with extreme sturdiness and outfitted with various safety elements to safeguard the well-being of their users at all times.

When all other electrical controls on a pressure vessel fail, the safety valve is the last line of defense. Following the guidelines provided by the sterilizer and/or valve manufacturer and local inspection and insurance agencies, the safety valve must be inspected, tested, and verified to be in proper working order.

5. Waste-Water Cooling Mechanism

Effluent (air, steam, and condensate) from many autoclaves is cooled before it is drained. Effluent with a temperature of more than 140 degrees Fahrenheit is often prohibited from draining into the sewer system. Steam must be cooled before it can be poured down the drain to protect the building's drainage pipes.

The most straightforward approach to cooling this steam is to combine it with more cold tap water, however, due to the volume of water needed, an autoclave can be a significant contributor to a building's overall water use.

There are autoclaves available with features that drastically cut down on or remove the need for water altogether.

6. Vacuum System

Assuming a vacuum system is present, replacing the air inside the autoclave chamber with steam is essential for successful sterilization. Porous materials like animal bedding or linen, as well as containers with small apertures like flasks or commodities in bags, have a tendency to retain air pockets after sterilization. The goods will not be sterile if they include any bacteria that survive in an air pocket during the cycle.

7. Steam Generator

Most autoclaves get their steam supply from a central boiler in the home. An electric steam generator (or boiler) is required if one does not have access to or is unable to use domestic steam for the autoclave. Electric heating components are used in these boilers, which are normally located beneath the autoclave chamber.

FAQs: Autoclaves & Sterilizers

Q. How much does an autoclave cost?

Ans. Typically, the cost of an autoclave machine is Rs 10,000- Rs 2.5 lakhs in India.

Q. What is the use of a sterilizer?

Ans. In order to avoid the spread of diseases that can be contracted through using an item, sterilization involves the complete elimination of all bacteria present on or in the fluid making up the item.

Q. Who invented the autoclave machine?

Ans. The famous French microbiologist Charles Chamberland invented the new version of the autoclave machine in 1679.

Q. What are the main types of sterilizers?

Ans. Vacuum Sterilizers, large-sized sterilizers, Peracetic Acid Sterilizers, Gravity displacement autoclaves, and high-speed pre vacuum sterilizers are some common types of sterilizers.

Manufacturers & Suppliers of Autoclaves & Sterilizers

Company Name | Member Since |

|---|---|

Dipesh Engineering Works Mumbai, India | 23 Years |

Meta-Lab Scientific Industries Mumbai, India | 16 Years |

Patel Scientific Instruments Pvt. Ltd. Ahmedabad, India | 15 Years |

Eie Instruments Private Limited Ahmedabad, India | 15 Years |

Bioline Technologies Thane, India | 14 Years |

Utech Projects Pvt. Ltd. Mumbai, India | 14 Years |

Hmg (India) Palghar, India | 13 Years |

Becta Laboratories Surat, India | 12 Years |

Tavron Engineers Chennai, India | 12 Years |

Steri - Techno Fab Ahmedabad, India | 10 Years |

Popular Products