Storage Silos

(759 products)Stainless Steel Silo - 20 Feet Height, Cone Bottom Design | Corrosion-Resistant, Custom Sizes Available, Gray Finish

Price: 95000 INR/Piece

MOQ1 Piece/Pieces

ColorGray

Product TypeStainless Steel Silo

Height20 Foot (ft)

Bottom TypeCone

Voltage110-220 Volt (v)

Parul Engineering Private Limited

Pune

Trusted Seller

Trusted Seller3 Years

Super Premium

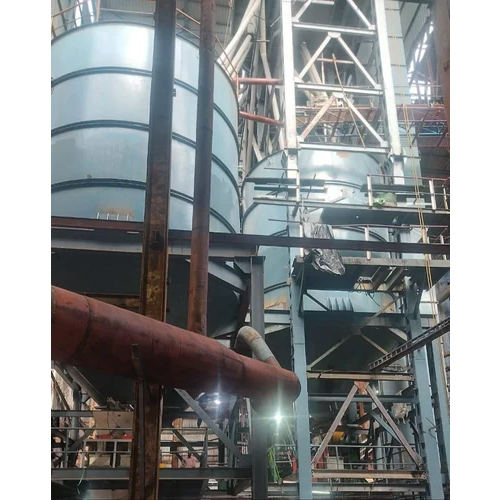

Super PremiumSteel Grain Storage Silo Application: Industrial

Price: 95000 INR/Piece

MOQ1 Piece/Pieces

ColorGray

Product TypeGrain Storage Silo

MaterialSteel

FinishPolished

ApplicationIndustrial

Warranty1 year

Innovative Engineering Works

Ahmedabad

Mild Steel Conical Bottom Silo Capacity: 15000 Liter/Day

Price: 100000 INR/Set

MOQ1 Set/Sets

Colorother

Product TypeMild steel conical bottom silo

MaterialOther, Stainless steel

TypeBroaching, Milling, Turning, Chemical Machining, Other, Drilling, Laser Machining, Etching

Capacity15000 Liter/day

ComputerizedYes

Labh Projects Pvt. Ltd.

Ahmedabad

Super Seller

Super SellerSunrise Process Equipments Private Limited

Mumbai

Trusted Seller

Trusted Seller22 Years

Super Seller

Super SellerSupporting Structure Catwalk - Finish: Galvanized

MOQ1 Unit/Units

Product TypeIndustrial Supporting Structure Catwalk

MaterialSteel

FinishGalvanized

Bottom TypeCylinderical

UsageIndustrial

WarrantyYes

Prominence Systems Pvt Ltd

Bhosari

Trusted Seller

Trusted Seller2 Years

Super Seller

Super SellerCement Silo System

Price Trend: 1000000.00 - 2000000.00 INR/Piece

MOQ1 Piece/Pieces

Supply Ability1 Per Week

Delivery Time1 Week

Kaushik Engineering Works

Ahmedabad

Trusted Seller

Trusted Seller18 Years

Super Seller

Super SellerWheat Storage Tank Application: Industrial

Price: 25000000 INR/Unit

MOQ1 Unit/Units

MaterialSteel

FinishGalvanized

Bottom TypeCylinderical

ApplicationIndustrial

WarrantyYes

Krishna Grain Systems Pvt. Ltd.

Pune

Trusted Seller

Trusted Seller3 Years

Super Seller

Super SellerFarm Storage Silo

Price: 500000 INR/Kilograms

MOQ01 Kilograms/Kilograms

Supply Ability1 Per Month

Delivery Time1 Months

Steel Storage Silo System

Price Trend: 100000.00 - 1000000.00 INR/Piece

MOQ1 Piece/Pieces

MaterialSteel

Warranty1 year

Rcrisp Solutions India Private Limited

Greater Noida

Trusted Seller

Trusted Seller3 Years

Super Seller

Super SellerAdmech Equipment (india) Pvt. Ltd.

Indore

Trusted Seller

Trusted Seller9 Years

Super Seller

Super SellerStorage Silos - Application: Industrial

Price: 735000.0 INR/Unit

MOQ1 Unit/Units

Product TypeStorage Silos

MaterialOther

ColorGrey

Voltage220-440 Volt (v)

UsageIndustrial Storage

ApplicationIndustrial

Sand Storage Silo, Storage Material: Cement, Fly Ash, Limestone, Chemicals, Grains

Product DescriptionSand Storage Silo

Destiny Solution And Engineers

Ahmedabad

Trusted Seller

Trusted Seller6 Years

Premium Seller

Premium SellerSS and MS Storage Silo

Price: 10000 INR/Unit

MOQ1 Unit/Units

FOB PortVadodara

Payment TermsCash Advance (CA), Cash in Advance (CID), Cheque, Others

Supply Ability100 Per Month

Prime Advance Polishing System Pvt. Ltd.

Vadodara

Trusted Seller

Trusted Seller16 Years

Super Seller

Super SellerWhite Milk Storage Tank

Product DescriptionWe are a prominent Exporter, Manufacturer & Supplier of Silos based in Rajahmundry, Andhra Pradesh, India. SS Engineers fabricate bulk milk storage equipment for dairies. These milk storage tanks are available in different models to suit requirements. The standard models include vertical milk storag

Ss Engineers And Consultants Private Limited

Rajahmundry

Galvanized Industrial Grain Storage Silos

MOQ1 Unit/Units

MaterialSteel

FinishGalvanized

Bottom TypeCone

UsageIndustrial

WarrantyYes

Rajdeep Engineering Systems Pune Private Limited

Pune

Super Seller

Super SellerFly Ash Silo - Application: Rmc

Price: 500000 INR/Number

MOQ1 Number

Surface ColorAny Color

ColorAs per client

Thickness5 mm, Bottom Cone - 6 mm Millimeter (mm)

Product TypeMild Steel

MaterialSteel

Surface FinishPowder Coated

Knovocon Private Limited

Kolkata

Trusted Seller

Trusted Seller3 Years

Super Seller

Super SellerZincalume Hopper Bottom Silo Application: Industrial

Price: 7000000.0 INR/Unit

MOQ1 Unit/Units

Product TypeHopper Bottom Silo

MaterialOther

CapacityAvailable in 50 ton to 10000 ton Ton/day

FinishCoated

ColorSilver

HeightCUstomized Foot (ft)

Everyday Steel Storage Private Limited

Greater Noida

Trusted Seller

Trusted Seller7 Years

Premium Seller

Premium SellerPaddy Storage Silo Capacity: 200-250 Ton/Day

Price Trend: 1000000.00 - 1200000.00 INR/Ton

MOQ5 Ton/Tons

Product TypePaddy storage silo

MaterialSteel

Capacity200-250 Ton/day

FinishCoated

ColorGrey

Height50 Foot (ft)

Skf Engineering Pvt. Ltd.

Kurukshetra

Trusted Seller

Trusted Seller9 Years

Premium Seller

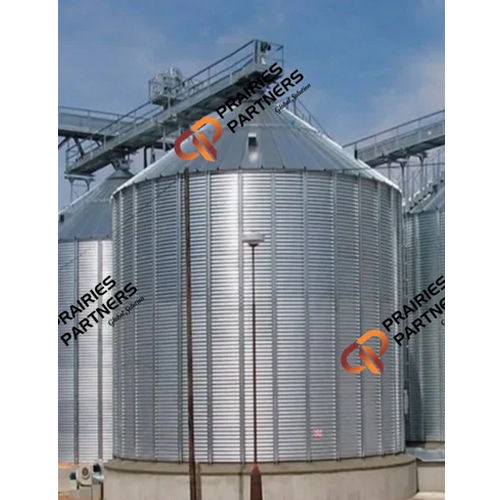

Premium SellerSilver Flat Bottom Storage Silos

Price: 4500000 INR/Unit

MOQ1 Unit/Units

Product Type15m Flat Bottom Storage Silos

FinishPolished

ColorSilver

Height15 Meter (m)

UsageIndustrial

WarrantyYes

Prairies Partners Global Solution

Ghaziabad

2 Kl Mild Steel Tank - Capacity: 2000 Ltr

Price: 348000 INR/Unit

MOQ1 Unit/Units

MaterialSteel

Capacity2000 Ltr

Height40 Foot (ft)

UsageIndustrial

Mechno Tech

Dewas

Trusted Seller

Trusted Seller6 Years

Super Seller

Super SellerSs Milk Silo - Capability: 10000-20000 Ltr

Price: 600000 INR/Unit

MOQ1 Unit/Units

ColorWhite And Silver

Product TypeSS Milk Silo

MaterialSteel

FinishCoated

Capability10000-20000 Ltr

Bottom TypeCylinderical

Dhvani Engineering Works

Ahmedabad

Trusted Seller

Trusted Seller7 Years

Super Seller

Super SellerPolished Mild Steel Storage Silo

Price: 1700000 INR/Unit

MOQ1 Unit/Units

MaterialSteel

FinishPolished

Bottom TypeCylinderical

UsageIndustrial

Nilkanth Machine Tools

Ahmedabad

Trusted Seller

Trusted Seller3 Years

Premium Seller

Premium SellerHeavy Duty Grain Storage Silo - Color: As Per Requirement

MOQ100 Square Foot/Square Foots

MaterialSteel

FinishGalvanized

ColorAs Per Requirement

Bottom TypeCylinderical

UsageIndustrial

Warranty5 Years

Lgs Projects Private Limited

Greater Noida

Trusted Seller

Trusted Seller1 Years

Premium Seller

Premium SellerPolished Industrial Storage Silo

MOQ1 Unit/Units

MaterialSteel

FinishPolished

Bottom TypeCylinderical

UsageIndustrial

WarrantyYes

Uma Techno Fab

Mehsana

Trusted Seller

Trusted Seller2 Years

Premium Seller

Premium SellerSilo Pilot - Color: White

Price: 68000 INR/Unit

MOQ1 Unit/Units

ColorWhite

MaterialOther, Stainless steel

FinishPolished

Voltage220-240 Volt (v)

UsageIndustrial

Warranty1 Year

Mm Despro Engineering Pvt. Ltd.

Delhi

Trusted Seller

Trusted Seller1 Years

Premium Seller

Premium SellerCement Flyash Silo - Finish: Polished

Price: 540000 INR/Unit

MOQ1 Unit/Units

MaterialOther, Mild Steel

FinishPolished

Height50 Foot (ft)

Voltage380-440 Volt (v)

UsageIndustrial

Warranty1 Year

3 Madhura Handling Systems

Bengaluru

Trusted Seller

Trusted Seller7 Years

Premium Seller

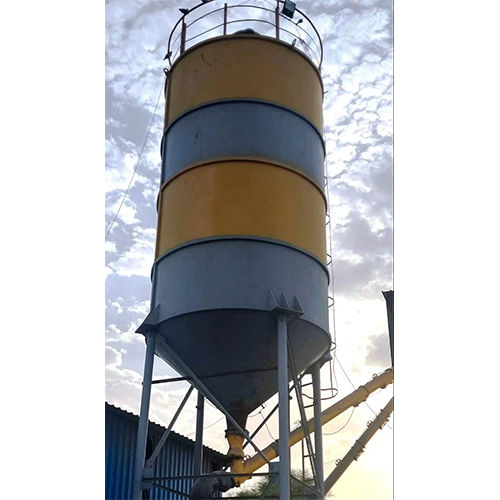

Premium SellerYellow-Grey 100 Mt Cement Silo

Price: 480000 INR/Piece

MOQ1 Piece/Pieces

ColorYellow-Grey

Product Type100 MT Cement Silo

MaterialSteel

FinishPainted

UsageIndustrial

Warranty1 Years

Lh Infracon Private Limited

Greater Noida

Trusted Seller

Trusted Seller6 Years

Premium Seller

Premium SellerMild Steel Cement Storage Silo - Finish: Polished

MOQ1 Unit/Units

Product TypeMild Steel Cement Storage Silo

MaterialSteel

FinishPolished

Bottom TypeCylinderical

UsageCommercial

WarrantyYes

Gyantosh Fabricators Private Limited

Indore

Trusted Seller

Trusted Seller2 Years

Premium Seller

Premium SellerLatest From Storage Silos

Grain Storage Silos

By:

Sidhivinayak Agri And Automation

Zincalum Grain Storage Silos

By:

Prairies Partners Global Solution

Hopper Bottom Storage Silos

By:

Bhupati Engineering

Aluminum Storage Silos

By:

Invoit Plast Machinery Private Limited

Wheat Storage Silo

By:

Prime Solution Silo

Ready To Ship Storage Silos

Storing for the Future: An Overview of Silos

The silos mainly refer to large, independent storage facilities mainly made from stainless steel or mild steel. They are frequently used to store agricultural products like grain, though they can also be used to store other materials like cement or coal. One of the advantages of these silos is that they help in keeping the materials dry and contaminant-free, protected from the outer environment for a longer time. This is particularly important for agricultural products because moisture and dust can spoil the crop and lower its value.

Typically cylindrical in shape, they have a hopper or flat bottom that makes unloading simple. These silos are also designed in different ways to suit the requirements of the industries. Most industrial silos are vertically aligned, but there are horizontally aligned silos as well for storing liquid products, like milk, and dry materials, like sand.

In general, silos are a crucial tool for safeguarding materials in a range of settings.

History and Development of Silos

Ancient civilizations used subterranean pits to store grain, and are known to have used silos. Wooden silos were frequently used to store grain and other agricultural products in medieval Europe. The late 19th century saw the creation of the first modern silos. An improved silo design using reinforced concrete was patented in 1873 by a French engineer by the name of Auguste Génieys, making the silos more robust and able to support heavier loads.

In McHenry County, Illinois, a farmer named Fred Hatch constructed the country's first modern silo in 1875. Hatch's silo was 30 feet tall and constructed of brick.

Early in the 20th century, bigger and more durable silos were built, thanks to the introduction of new materials like steel and reinforced concrete. The ability to automate the loading and unloading of silos had also increased their efficiency and reduced their cost.

Today, storage silos are used in many different industries and are available in a variety of sizes and construction materials. They remain a crucial tool for material storage and protection and are an integral part of many industrial and agricultural operations.

Benefits of Silo Storage for Livestock Feed

Silos are frequently employed in the agricultural sector to store animal feed, and doing so has a number of advantages:

·Offers weather protection

·Feeds quality preservation

·Utilizes farm storage space effectively

·Simple handling of feed

· Reduces feed waste and spoilage

·Helps farmers to save money

Hence, silo storage for livestock feed has a number of benefits, including weather protection, feed quality preservation, effective space utilization, simple handling, and cost savings. Due to these advantages, silo storage is a crucial component of contemporary livestock farming.

Uses of Silos

These offered silos have a lot of uses. Some of these applications are as follows:

· These flat bottom and hopper storage silos are used to store tea, soybeans, maize, wheat, rice, and other crops, in the agriculture industry

· These silos are also used for the storage of livestock feed; by-products of the farming and industrial processes.

· Silos can also be used to store a variety of chemicals, such as pesticides, fertilizers, and other dangerous substances.

· At construction sites, cement and bitumen are also stored in bulk amounts in silos.

· The industrial silos are also designed to be used to store powders that are frequently used in the food industry, such as flour, sugar, and baking soda.

· In wastewater treatment facilities, silos are used to store wastewater and other liquids.

These silos are very crucial structures to have, as they help in protecting the materials for the long term.

Size and Capacity

Silos are available in a variety of shapes, sizes, and capacities to meet a variety of requirements in industrial settings. The type of material being stored, the silo's intended use, and the available space are just a few factors that affect a silo's size and capacity.

A silo's size and capacity can be altered to suit particular requirements. According to shifting storage needs, some manufacturers offer modular silo systems that can be sized up or down.

In conclusion, a silo's size and capacity depend on a number of variables, including the kind of material being stored and the silo's intended use. Silos come in a variety of sizes, from modest residential storage silos to substantial industrial silos, and can be tailored to suit particular requirements.

Types of Silos

There are different types of silos designed for various industries, including manufacturing, construction, and agriculture. The following are a few of the most typical silos:

1. Tower silos: These silos are tall, cylindrical buildings that are frequently used to store grain and silage.

2. Bunker silos: The silos are buried rectangular structures that are low to the ground. They are frequently employed to store agricultural products like silage.

3. Bag silos: The big, flexible bags made of sturdy plastic or other materials refers to as these silos. They are frequently used to store agricultural products like hay, grain, and other. The installation of bag silos is simple, and they can be moved if necessary.

4. Cone-Shaped Silos: These hopper silos are widely used to store cement, chemicals, and other materials. They can be made of steel or concrete and are designed to make it simple to discharge the material that has been stored.

5. Steel silos: They are constructed of galvanized steel and are made to withstand weather conditions like wind and rain. These silos are widely used to store and save grain, cement, and other materials frequently.

6. Concrete silos: These silos are mainly used to store cement, grain, and other materials safely. They are constructed of reinforced concrete and are made to withstand weather conditions like wind and rain.

FAQs: Storage Silos

Q. What are silos, and what are they used for?

Ans. To store bulk materials like grains, cement, chemicals, or food products, these silos are widely used. These structures are commonly used in various industries such as agriculture, construction, and manufacturing. They are widely made from different materials like concrete, steel, or plastic.

These silos come in a range of sizes and capacities. They are mainly designed to protect stored materials from environmental factors such as moisture, insects, and rodents and can also prevent contamination.

In agriculture, silos are used for storing animal feed, grains, and silage. They are also used for storing cement, sand and other building materials, as well as raw materials and finished products for the construction and manufacturing industry.

With the help of these silos, you can reduce storage costs, improve inventory management, and increase efficiency in handling and transporting materials. To have the stored materials in good condition, these silos help in preserving the quality and integrity of these materials.

For providing an efficient and effective way to store bulk materials, these silos act as the best option for many industries.

Q. What factors should be considered when selecting a silo for storage?

Ans. To make sure that the silo chosen for storage satisfies the requirements of a specific application, it is important to take into account a number of factors. Following are some important points to think about:

·Consider the product that will be stored in the silo.

·Determine the storage capacity based on the amount of product to be stored and how frequently the silo needs to be refilled.

·Look at how the product will be lowered into and removed from the silo.

·To construct silos, different types of materials are used. Concrete, steel, plastic, and wood are some examples. Select the silo that is right for the product.

·Silos range in price according to their size, composition, and features. Select the silo as per your budget.

Hence, the right silo selection can guarantee ideal storage conditions, increase the effectiveness of material handling, and lower maintenance costs.

Q. How do silos improve the efficiency and quality of crop storage in agriculture?

Ans. The effectiveness and quality of crop storage in agriculture can be greatly enhanced by silos. Here are some strategies silos can use to accomplish this:

·Silos shield crops from moisture, pests, and rodents as well as other environmental hazards. This lessens the possibility of crop spoilage and preserves the crop's quality.

·Silos allow for better inventory control because farmers can store crops in large quantities and easily keep track of their stock levels. They can now plan their operations and improve their supply chain thanks to this.

·Silos require less labor to load and unload crops than conventional storage methods, which lowers labor costs. As a result, farmers may save time and money and operate more effectively overall.

·Farmers can store crops locally in silos, eliminating the need to transport them frequently to off-site storage facilities. This can lower the risk of crop damage during transport and save farmers money on transportation costs.

·Silos have a greater capacity for storage, allowing farmers to benefit from economies of scale by storing large quantities of crops.

·Silos can aid in the preservation of a crop's nutritional value because they offer a controlled environment for storage.

·Silos can also vastly enhance the effectiveness and calibre of crop storage in agriculture. They help farmers increase their profits and more effectively meet consumer demand for crops by lowering costs, enhancing inventory control, and preserving crop quality.

Q. What is the cost of a silo in India?

Ans. Now let's understand the price of the silo. The price of a silo depends on various factors, including:

·Type of silo

·Capacity

·Construction material

In India, small to medium silos can range between INR 3 Lakhs and INR 15 Lakhs, whereas larger silos can range up to INR 50 Lakhs or more.

So, when planning an overall budget for a silo, there are some additional expenses too, like shipping, installation, and ongoing maintenance and repairs which should be taken into account. A silo's price may also change based on the location, the accessibility of materials, and the need for skilled labor.

For a more precise cost estimate of a silo based on your unique requirements and needs, it is advised to speak with a reputable silo manufacturer or supplier in India.

Manufacturers & Suppliers of Storage Silos

Company Name | Member Since |

|---|---|

Sunrise Process Equipments Private Limited Mumbai, India | 22 Years |

Kaushik Engineering Works Ahmedabad, India | 18 Years |

P-Square Technologies Pune, India | 16 Years |

Prime Advance Polishing System Pvt. Ltd. Vadodara, India | 16 Years |

Admech Equipment (India) Pvt. Ltd. Indore, India | 9 Years |

Ss Engineers And Consultants Private Limited Rajahmundry, India | 9 Years |

Skf Engineering Pvt. Ltd. Kurukshetra, India | 9 Years |

Indoinfy Steelcorp Faridabad, India | 7 Years |

Everyday Steel Storage Private Limited Greater Noida, India | 7 Years |

Dhvani Engineering Works Ahmedabad, India | 7 Years |

Popular Products